| Reusable Artifact | Descriptions |

|---|---|

| Artifact Type | Enhancement - BADI |

| Functional Area | MM |

| Functional Sub-Area | IM, QM |

| SAP System | ECC |

Objective:

This document is for creation of automatic usage decision upon specific business scenario.

In any business process regarding vendor transactions there will be trusted material in each transaction. There is a common scenario that need of QA inspection for this material from that particular vendor (or trusted vendor) is null. This scenario is not available or executed in standard SAP installation. The proposed approach as described below will allow businesses to go for automatic inventory update under specific conditions.

Target Audience:

Both functional (MM & QM) and technical (ABAP developer) can use this document.

Requirement & Overview:

Normally vendor sends their finished goods as part of business process (like vendor consignment process). Later on, inspection will be done on the goods either manually or automatically by a third-party system. After the inspection is completed, they post the Goods receipt (GR) using the MIGO transaction. For trusted vendor and trusted material, inspection will be done automatically and MIGO is posted. (But, UD update must be done automatically)

Needs to be created or Pre requisites:

- Custom table ZAUTO_UD needs to be created. (To store trusted material and vendor details along with mapping them).

- Custom Function module ‘ZUPDATE_UD’ needs to be created. (To update Usage decision for inspection lot)

Technical design or steps to achieve a functionality:

In a standard SAP process, Inspection lot number (I-L no) and Material document number (M-doc-no) will be generated once MIGO is done. During Quality inspection, I.L no will be accepted in IL02 transaction.

In our customer business process as per business requirement, Quality inspection will be automated once M-doc-no is generated. To achieve this, we need to enhance the BADI "MB_DOCUMENT_BADI" in the interface “IF_EX_MB_DOCUMENT_BADI”.BADI details:

| BADI | Description |

|---|---|

| BAdI Definition | MB_DOCUMENT_BADI |

| Description | BAdIs During Creation of a Material Document |

| Interface | IF_EX_MB_DOCUMENT_BADI |

| Implementation Name | ZMB_DOCUMENT_BADI |

| Description | MB_DOCUMENT_BADI - QM Enhancement for auto UD for trusted Parts |

Method:

| Method Name | Description |

|---|---|

| MB_DOCUMENT_BEFORE_UPDATE | Exit After Writing a Material Document. Not in 'update task' |

Functionality: Implement below logic into method MB_DOCUMENT_BEFORE_UPDATE.

Get inspection lot number, material number and vendor number from the importing parameter of (XMSEG –QPLOS, XMSEG-MATNR, and XMSEG-LIFNR). Call custom update Function module ‘ZUPDATE_UD’ using below parameters via Update task.(CALL FUNCTION 'ZUPDATE_UD' IN UPDATE TASK) Below function module needs to be created:Function module: ZUPDATE_UDDescription: UD update for inspection lot in MIGOImporting parameters:

| Parameter Name |

| Description and Mandatory |

|---|---|---|

| I_NUMBER | BAPI2045UD-INSPLOT | Inspection Lot |

| I_MATNR | QALS-MATNR | Material Number |

| I_LIFNR | QALS-LIFNR | Vendor Number |

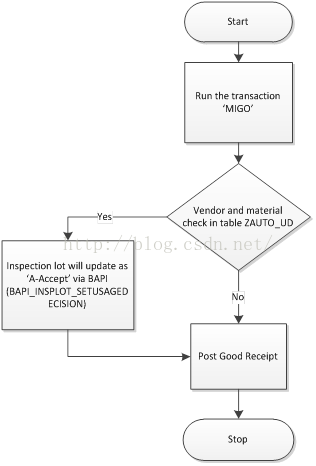

Function module: ZUPDATE_UD Check if material and vendor exist in custom table ZAUTO_UD. If material and vendor combination has found in the table then it’s a trusted transaction else normal transaction.Note:Custom table ZAUTO_UD will hold the trusted material and vendor combination details.If it’s a trusted transaction then call BAPI ‘BAPI_INSPLOT_SETUSAGEDECISION’ to updated Usage Decision as A (A = Accept) else don’t update.Process Flowchart:

Additional information:

- We can use email functionality to trigger email to manager after User decision update.

- We can trigger workflow for approvals.

Code snippet:

BADI Implementation : ZMB_DOCUMENT_BADI

************************************************************************************************************

* Title : QM Enhancement for auto UD for Req.Parts *

* BADI Definition Name : MB_DOCUMENT_BADI *

* Implementation Short Text : MB_DOCUMENT_BADI - QM Enhancement for auto UD for Req.Parts *

* BADI Implementation Name : ZMB_DOCUMENT_BADI *

* Method : MB_DOCUMENT_BEFORE_UPDATE (IF_EX_MB_DOCUMENT_BADI~MB_DOCUMENT_BEFORE_UPDATE) *

*----------------------------------------------------------------------------------------------------------*

*......next change..... *

************************************************************************************************************

METHOD if_ex_mb_document_badi~mb_document_before_update.

*Local Structures

DATA : ls_xvm07m LIKE LINE OF xvm07m, " Fields: Update Control of Module Pool SAPMM07M

ls_xmseg LIKE LINE OF xmseg, " Segment of Material Document

*Clear Variables

CLEAR: ls_xvm07m, ls_xmseg.

*Read Inspection lot number

READ TABLE xvm07m INTO ls_xvm07m INDEX 1.

*Read material and vendor number

READ TABLE xmseg INTO ls_xmseg INDEX 1.

*Update Usage Decision as 'A - Accept'

CALL FUNCTION 'ZUPDATE_UD' IN UPDATE TASK

EXPORTING

i_number = ls_xvm07m-qplos

i_matnr = ls_xmseg-matnr

i_lifnr = ls_xmseg-lifnr.

IF sy-subrc <> 0.

MESSAGE 'Error while calling update function module' TYPE 'E'.

ENDIF.

ENDIF.

ENDMETHOD.

*******************************************************************************************

Function module: ZUPDATE_UD

FUNCTION zupdate_ud.

*"----------------------------------------------------------------------

*"*"Update Function Module:

*"

*"*"Local Interface:

*" IMPORTING

*" VALUE(I_NUMBER) TYPE BAPI2045UD-INSPLOT

*" VALUE(I_MATNR) TYPE QALS-MATNR

*" VALUE(I_LIFNR) TYPE QALS-LIFNR

*" EXCEPTIONS

*" E_ERROR

*" E_SUCESS

*"----------------------------------------------------------------------

************************************************************************

* Title : QM Enhancement for auto UD for Req.Parts *

* Author : Akshath L.T *

* Creation Date : 24/11/2014 *

* Description : UD update for insp.lot from MIGO *

************************************************************************

* Local Structures

DATA: ls_ud_data TYPE bapi2045ud, " Data for making the usage decision

ls_ud_return_data TYPE bapi2045ud_return," Return structure after the usage decision is made

ls_stock_data TYPE bapi2045d_il2, " Stock Data for Inspection Lot

ls_return TYPE bapireturn1, " Return Parameter

* Local Internal Tables

lt_system_status TYPE STANDARD TABLE OF bapi2045ss, " Inspection lot system status

lt_user_status TYPE STANDARD TABLE OF bapi2045us, " Inspection lot user status

l_insp_num TYPE bapi2045ud-insplot, " Inspection Lot Number

l_lifnr TYPE lifnr, " Vendor

l_matnr TYPE matnr. " Material

* Constants

CONSTANTS : lc_ud_selected_set TYPE bapi2045ud-ud_selected_set VALUE '01', " Selected Set of the Usage Decision

lc_ud_code_group TYPE bapi2045ud-ud_code_group VALUE '01', " Code Group of the Usage Decision

lc_ud_code TYPE bapi2045ud-ud_code VALUE 'A', " Accept Usage Decision

lc_language TYPE bapi2045la VALUE 'E', " Language

lc_msgtyp_e TYPE c VALUE 'E', " Error

lc_werks TYPE werks VALUE '9999'.

* Clear variables

CLEAR:l_matnr,

l_lifnr,

l_insp_num,

ls_ud_data.

IF i_matnr IS NOT INITIAL AND

i_lifnr IS NOT INITIAL.

* Fetch Material and Vendor data from the table ZAUTOUD

SELECT SINGLE matnr

lifnr

FROM zauto_ud

INTO (l_matnr, l_lifnr)

WHERE matnr = i_matnr

AND lifnr = i_lifnr.

if sy-subrc = 0.

* Remove leading-zero of Vendor number

CALL FUNCTION 'CONVERSION_EXIT_ALPHA_OUTPUT'

EXPORTING

input = i_lifnr

IMPORTING

output = l_lifnr.

* Populate data for BAPI updation

ls_ud_data-insplot = i_number.

ls_ud_data-ud_selected_set = lc_ud_selected_set.

ls_ud_data-ud_plant = lc_werks.

ls_ud_data-ud_code_group = lc_ud_code_group .

ls_ud_data-ud_code = lc_ud_code .

ls_ud_data-ud_stock_posting = abap_true.

l_insp_num = i_number.

* Update usage decision as Accept in inspection lot

CALL FUNCTION 'BAPI_INSPLOT_SETUSAGEDECISION'

EXPORTING

number = l_insp_num

ud_data = ls_ud_data

language = lc_language

IMPORTING

ud_return_data = ls_ud_return_data

stock_data = ls_stock_data

return = ls_return

TABLES

system_status = lt_system_status

user_status = lt_user_status.

IF ls_return-type = lc_msgtyp_e.

MESSAGE 'Error while updating Usage Decision' TYPE 'E'.

ENDIF.

ENDIF.

ENDIF.

ENDIF.

ENDFUNCTION.

2万+

2万+

被折叠的 条评论

为什么被折叠?

被折叠的 条评论

为什么被折叠?