25马力拖拉机最终传动及驱动轴设计

摘 要

随着拖拉机工业的发展,我国拖拉机产品的科研与设计水平逐步提高。拖拉机是用与牵引和驱动各种配套机具,完成农业田间作业、各种土石方工程作业、运输作业和固定作业等的动力机械。拖拉机必须和各种作业机具组成拖拉机机组才能完成各种作业。拖拉机最终传动是用来进一步增加传动系的传动比,履带拖拉机和某些轮式拖拉机的最终传动还用来提高后桥的离地间隙。最终传动要有适当的传动比;保证后桥处有足够的离地间隙;齿轮油足够的承载能力和支承刚度;靠近驱动轮的最终传动尤其要求有可靠的密封,最终传动一般采用外啮合圆柱齿轮传动或行星齿轮传动。外啮合圆柱齿轮最终传动按所处的位置分为内置式和外置式两种。

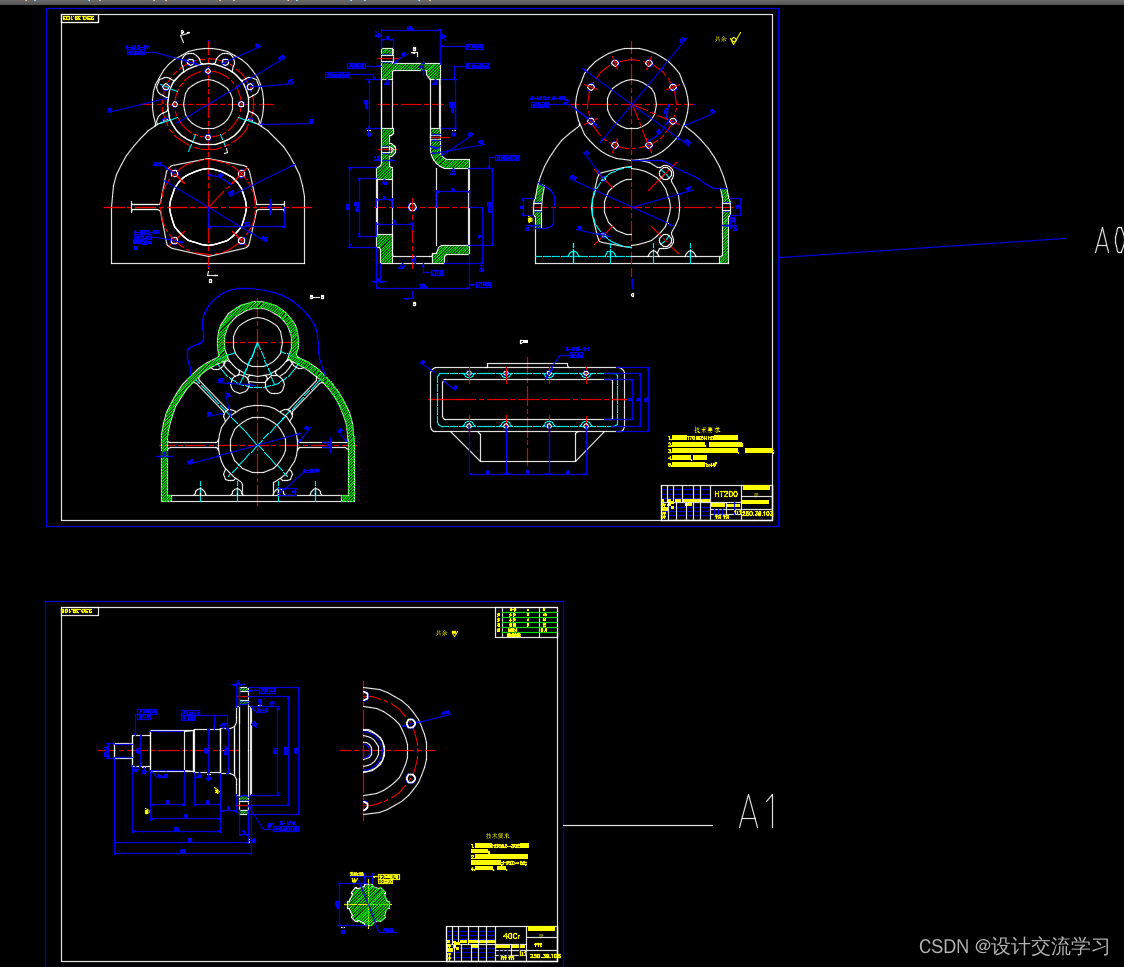

本次设计的最终传动采用了外啮合直齿圆柱齿轮最终传动,轴采用了矩形花键轴,轴承采用了圆柱滚子轴承和圆锥滚子轴承。

关键词: 拖拉机,最终传动,外啮合,圆柱齿轮,花键轴

DESIGN OF FINAL TRANSMISSION AND DRIVE SHAFTS OF 25 HP TRACTOR

ABSTRACT

Along with the tractor industry development, our country tractor product scientific research and the design level gradually enhance.The tractor is with with tows and actuates each kind of necessary machines and tools, completes the agricultural field work, each kindof cubic meter of earth and stone engineering work, the transportationwork and the fixed work and so on the power generator The tractor must be able to complete each kind of work with each kindof work machines and tools composition tractor unit. The tractor finaltransmission is uses for further to increase transmission system the velocityratio, the caterpillar tractor and certain wheeled tractors final transmissions also uses for to enhance the rear axle of car the groundclearance. The final transmission must have the suitable velocity ratio;Guaranteed the rear axle of car place has the enough ground clearance; gear oil enough bearing capacity and supporting rigidity ; Approaches the driving gear the final transmission especiallyto request to have the reliable seal outside, the final transmission generally uses meshes the cylindrical gears transmission or the planetgear biography In outside meshes the position which the cylindrical gears finaltransmission presses locates to divide into sets at the type andoutside sets at the type two kinds.

This design final transmission used outside meshed thecylindrical gears final transmission, the axis uses the rectangularspline shaft, the bearing has used the gulley ball bearing and thecircular cone roller bearings.

Key words: tractor,final transmission,outside meshes,cylindrical gears,spline shaft

目 录

第一章 前 言...................................1

- 拖拉机最终传动结构方案分析...............3

§2.1 最终传动的功用和要求.....................3

§2.2 最终传动的分类 ...........................3

§2.2.1 外啮合圆柱齿轮最终传动 ................3

§2.2.2 内啮合圆柱齿轮最终传动 .................7

§2.2.3 行星齿轮最终传动 .......................7

第三章 最终传动的主要参数确定...................9

§3.1 最终传动直齿圆柱齿轮的中心距 ............9

§3.1.1 对最终传动的基本要求是 ................9

§3.1.2 求中心距................................9

§3.2 齿轮各参数的选择与计算.... ............11

第四章 圆柱齿轮的结构强度计算..................14

§4.1 齿轮的校核................................14

§4.2 齿轮的强度应力计算........................14

§4.2.1 齿轮表面接触强度.......................14

§4.2.2 齿根弯曲强度校核.......................16

第五章 轴的确定与计算..........................19

§5.1 输入轴校核..........................19

§5.2 驱动轴(输出轴)设计与计算 .................22

第六章 轴承的校核...............................26§7.1 输入轴圆柱滚子轴承的校核..................26

§7.2 输出轴圆锥滚子轴承的校核..................26

第七章 总结 ....................................28

参考文献........................................29

致谢............................................30

…………

241

241

被折叠的 条评论

为什么被折叠?

被折叠的 条评论

为什么被折叠?