摘 要

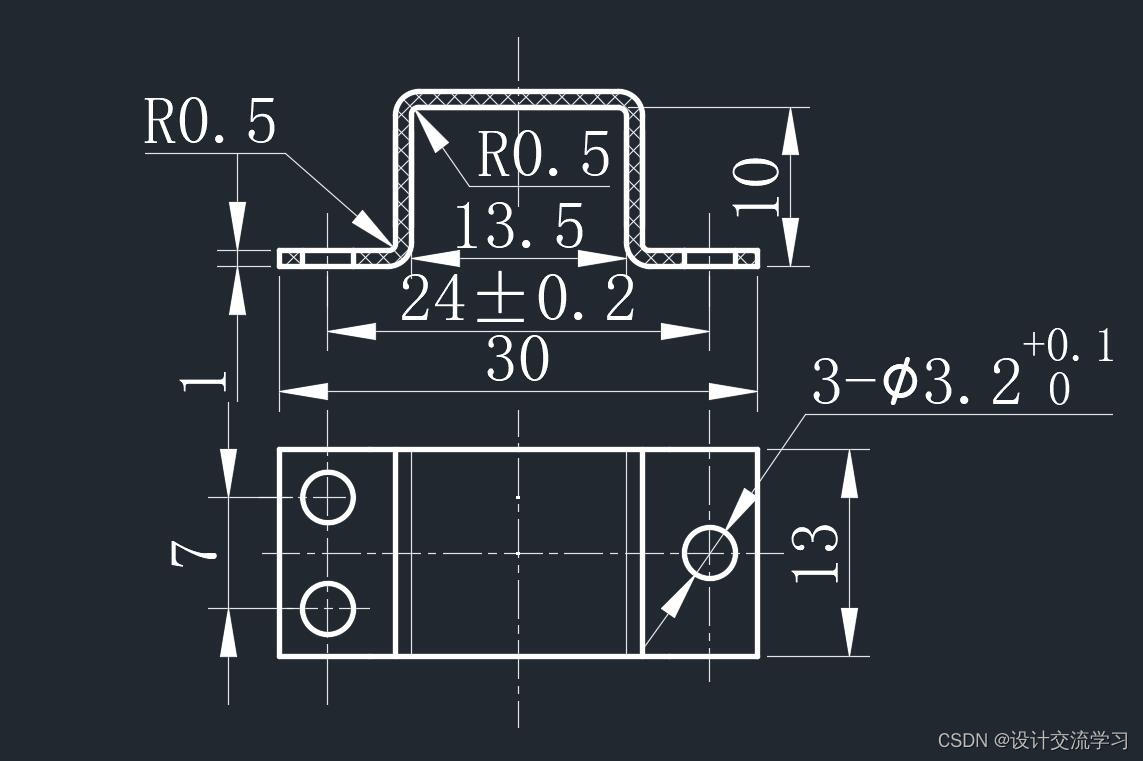

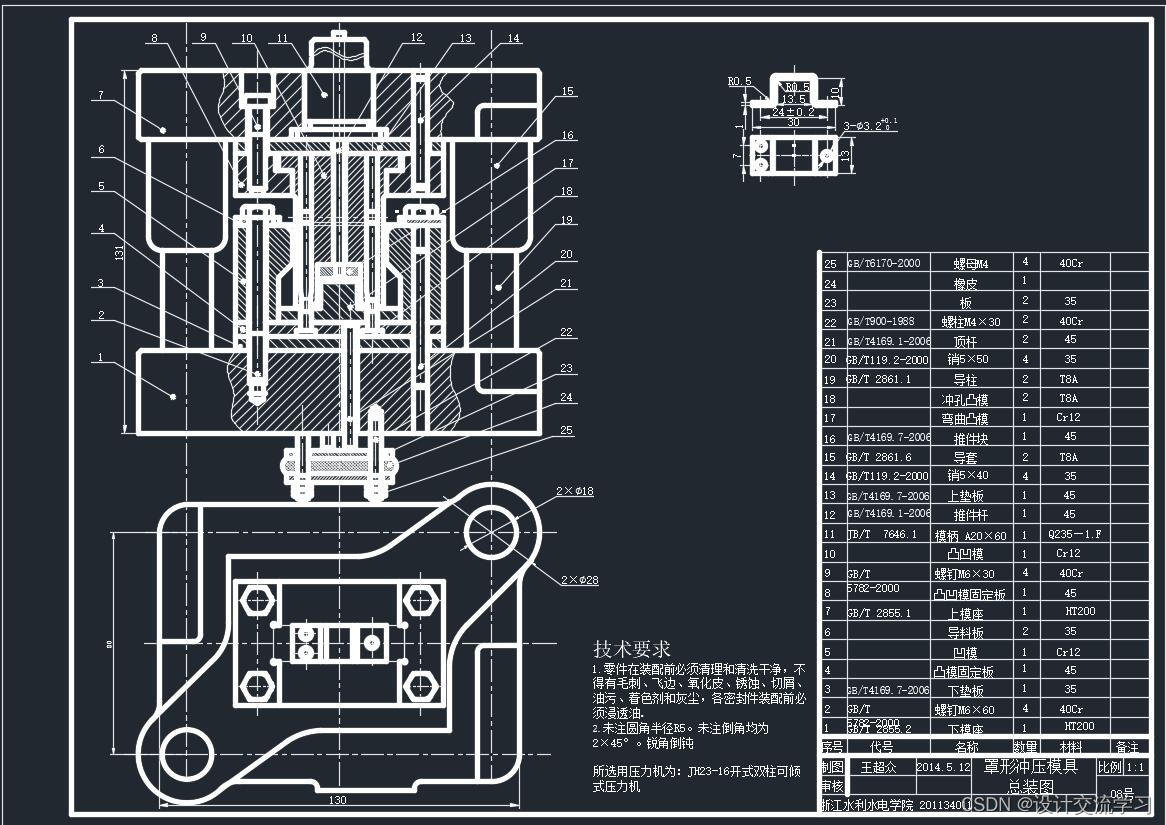

随着中国工业不断地发展,模具行业也显得越来越重要。本文针对罩形弯曲件的冲裁工艺性和弯曲工艺性,分析比较了成形过程的三种不同冲压工艺(单工序、复合工序和连续工序),确定用一幅复合模完成冲孔和弯曲的工序过程。介绍了罩形件冷冲压成形过程,经过对批量生产、零件质量、零件结构以及使用要求的分析、研究,按照不降低使用性能为前提,将其确定为冲压件,用冲压方法完成零件的加工,且简要分析了坯料形状、尺寸,排样、裁板方案,冲压工序性质、数目和顺序的确定,进行了工艺力、压力中心、模具工作部分尺寸及公差的计算,并设计出模具。还具体分析了模具的主要零部件(如冲孔凸模、卸料装置、弯曲凸模、垫板、凸模固定板等)的设计与制造,冲压设备的选用,凸凹模间隙调整和编制一个重要零件的加工工艺过程。列出了模具所需零件的详细清单,并给出了合理的装配图。通过充分利用现代模具制造技术对传统机械零件进行结构改进、优化设计、优化工艺方法能大幅度提高生产效率,这种方法对类似产品具有一定的借鉴作用。

关键词

罩形件;模具设计;复合模;冲孔;弯曲

ABSTRACT

As China's industrial development unceasingly, mould industry also appears more and more important. In the light of the blanking cover shape bending parts manufacturability and bending manufacturability, comparative analysis the forming process of the three different stamping process (single process, composite process and continuous process), determine the complete the punch with a picture of a composite modulus and bending processes. Cover cold stamping forming process is introduced, through to mass production, the quality of parts, parts structure as well as the use requirement analysis, the study, according to not reduce the usability for the premise, to be sure for stamping parts, complete parts processing, with stamping method and the brief analysis of the blank shape, size, layout, cutting board, the determination of nature of the stamping process, the number and order the technology force, pressure center, the calculation of working parts of die dimension and tolerance, and mold design. Also analyzes the mold of the main components (such as punching punch, discharging device of punch, bending, plate, punch plate, etc.) on the design and manufacturing, the selection of stamping equipment, convex concave die clearance adjustment and an important component of machining process. Lists the mold the detailed list of parts required, and gives the reasonable assembly drawing. By making full use of modern mould manufacturing technology to the traditional mechanical parts for structural improvement, optimization design, optimization of process method can greatly improve the production efficiently, this method has a certain reference value to the similar products.

Keywords

cover shape parts; mold design;compound die;punch;bend

目 录

……

文章分析了罩形弯曲件的冲裁和弯曲工艺,对比了单工序、复合工序和连续工序,确定采用复合模完成冲孔和弯曲。通过研究批量生产、零件质量和结构要求,进行了工艺设计,包括坯料尺寸、排样和工序顺序的确定,计算了工艺力和模具尺寸,并详细介绍了模具主要零部件的设计与制造,以及压力机的选择。利用现代模具技术提高了生产效率,对同类产品设计有参考价值。

文章分析了罩形弯曲件的冲裁和弯曲工艺,对比了单工序、复合工序和连续工序,确定采用复合模完成冲孔和弯曲。通过研究批量生产、零件质量和结构要求,进行了工艺设计,包括坯料尺寸、排样和工序顺序的确定,计算了工艺力和模具尺寸,并详细介绍了模具主要零部件的设计与制造,以及压力机的选择。利用现代模具技术提高了生产效率,对同类产品设计有参考价值。

623

623

被折叠的 条评论

为什么被折叠?

被折叠的 条评论

为什么被折叠?