摘 要

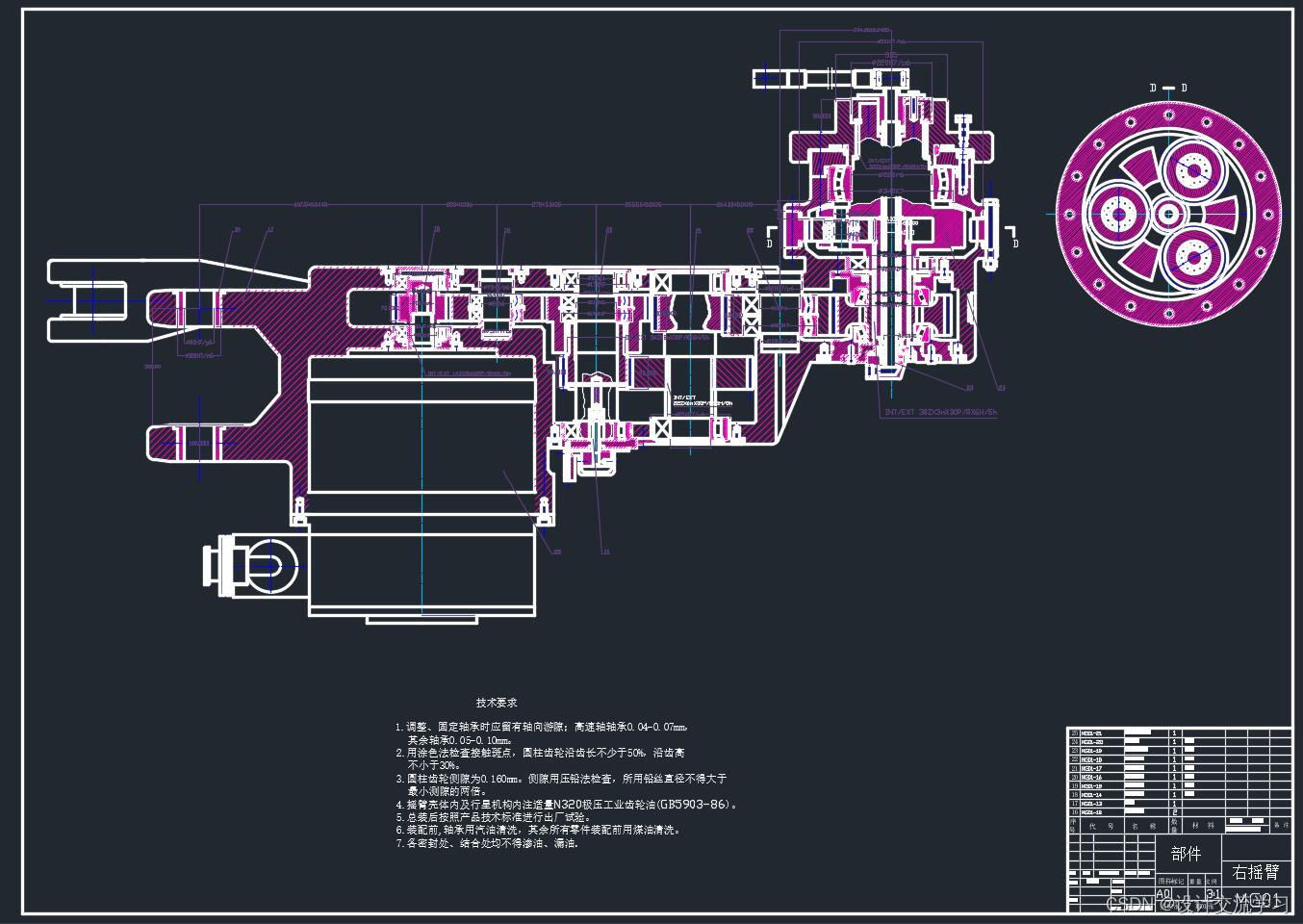

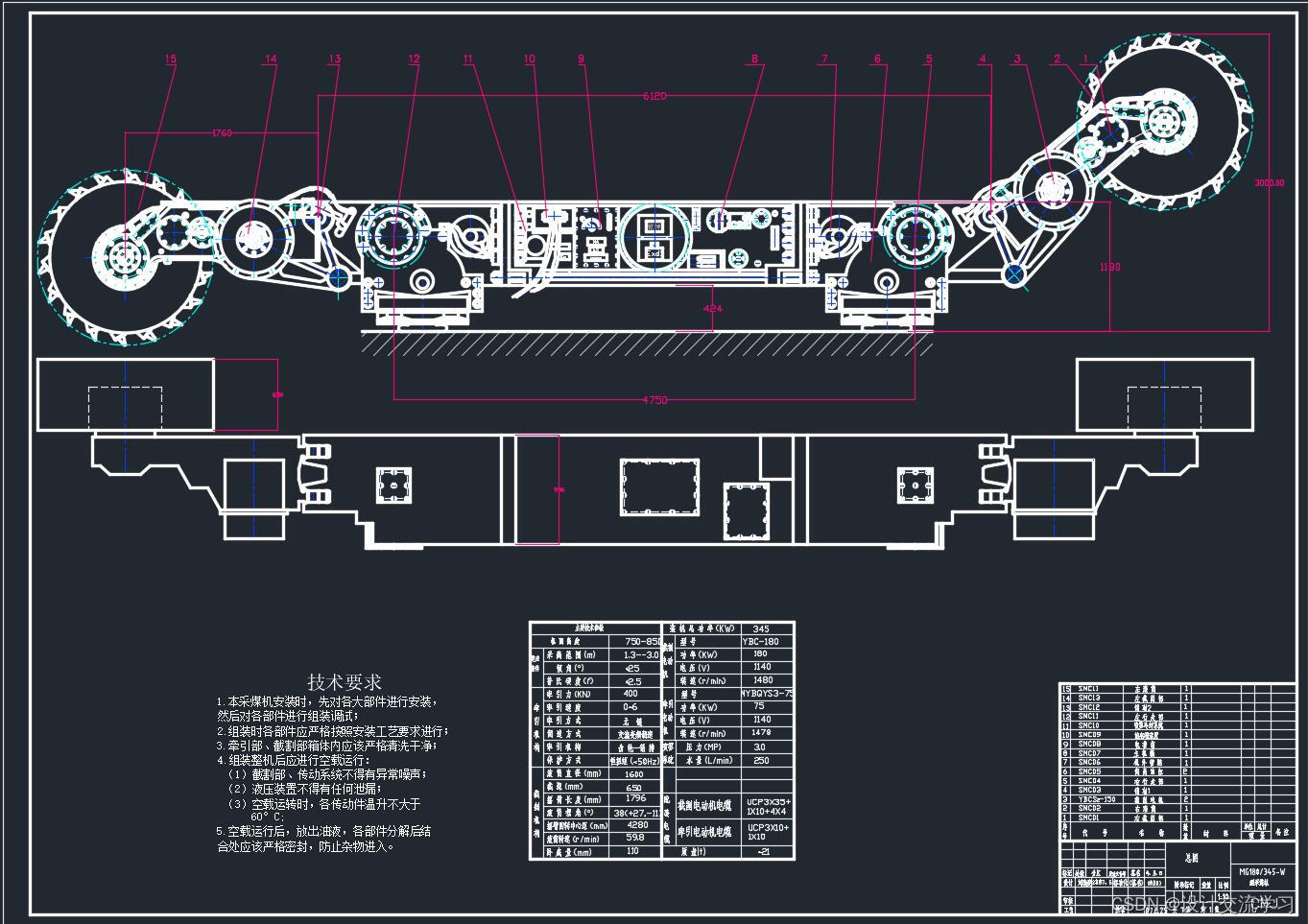

在参考国内外有关中厚煤层采煤机的情况下,完成了截割电机功率为180KW总装机功率为450KW的截割式滚筒液压牵引采煤机的整机方案设计及对采煤机截割部进行了重点设计。主机身采用整体结构形式,取消了长螺柱及传统意义上的螺栓联接;此结构简单、可靠,且尺寸小,大大的降低了采煤机的机身高度。截割部采用四级传动前三级为直齿传动,第四级为行星传动。在前三级的直齿传动利用直齿传动设计的一般原理,设计出适合截割部的齿轮传动依次分为截一轴系,惰一轴系,截二轴系,截三轴系,,惰二轴系;采用了两个惰轴系是本设计的创新点,它即满足了传动强度的要求又满足了截割高度对截割部长度的要求。在第四级行星传动中,用运2KH行星减速器设计的原理,设计出适合截割部的一级2KH型行星减速器,并将它和滚筒直接联结,大大简化了截割部的设计,节省了材料、空间。此外对截割部上的其它部分如离合器,内喷雾系统也进行了详细设计及校合。

关键词:

采煤机 截割部 行星轮减速器

ABSTRACT

Reference to the domestic and international thick seam Shearer circumstances, Cutting completed the electrical power of 180 KW total installed power of 450 KW of cutting-cylinder hydraulic traction Shearer Whole program design and right shearer cutting focus of the Department of Design. Host overall body structure, eliminating a long stud, and the traditional sense of the bolt; This structure is simple, reliable, and small size, greatly reducing the height of Shearer's fuselage. Cutting Part 4 used to drive before three straight tooth drive, the fourth level of planetary transmission. The former three straight drive gear teeth through the direct transmission of the general design principles, designed for cutting the Department of Gear were divided into a closed shaft, the shaft an inert, as of two shaft, up 3 shaft, and inert two shafts; using two inert shaft is the innovation in design, It is a drive to meet the strength to meet the demands of the cutting height on the cutting Minister degree requirements. In the fourth grade planetary transmission, and use Win two KH planetary reducer design principle, designed for cutting the Department of a two-KH planetary reducer, and it will directly link drum, greatly simplified the cutting of the design, saving materials and space. In addition to cutting the Department of the other parts such as clutch, which spray system also carried out a detailed design and a calibration.

Keywords:

Shearer;Cutting Department;Planetary gear reducer

…………

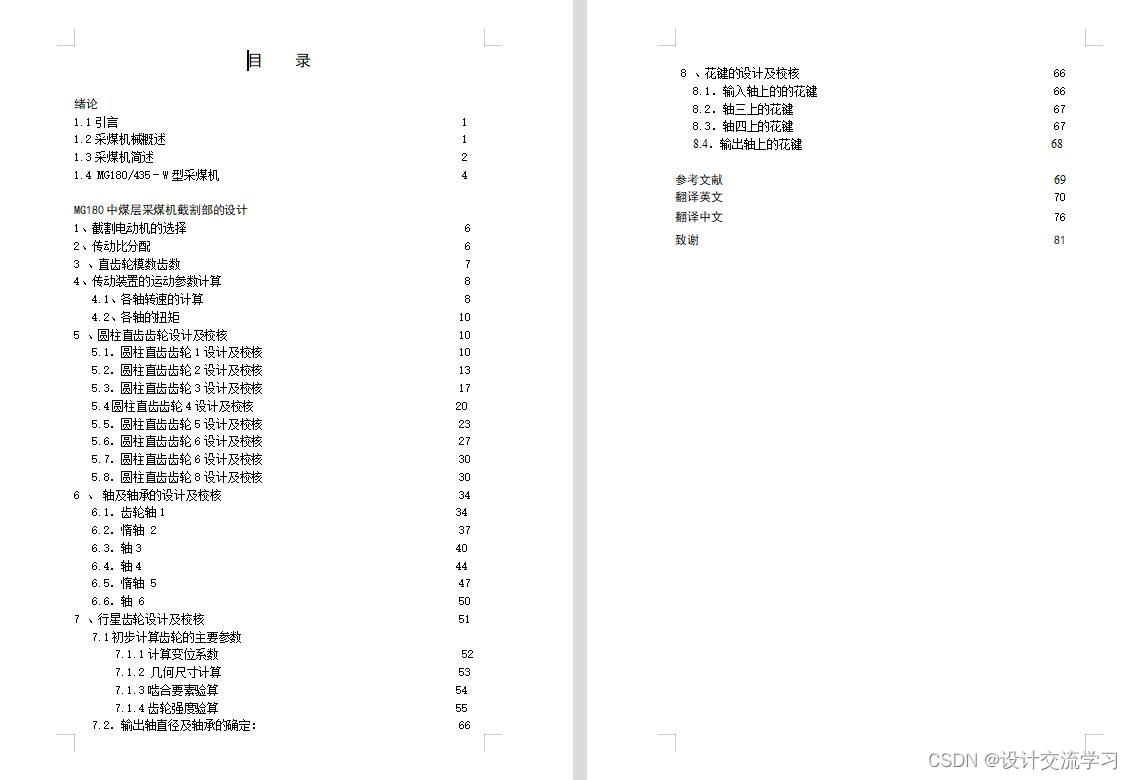

目 录

绪论

1.1引言 1

1.2采煤机械概述 1

1.3采煤机简述 2

1.4 MG180/435-W型采煤机 4

MG180中煤层采煤机截割部的设计

1、截割电动机的选择 6

2、传动比分配 6

3 、直齿轮模数齿数 7

4、传动装置的运动参数计算 8

4.1、各轴转速的计算 8

4.2、各轴的扭矩 10

5 、圆柱直齿齿轮设计及校核 10

5.1.圆柱直齿齿轮1设计及校核 10

5.2.圆柱直齿齿轮2设计及校核 13

5.3.圆柱直齿齿轮3设计及校核 17

5.4圆柱直齿齿轮4设计及校核 20

5.5.圆柱直齿齿轮5设计及校核 23

5.6.圆柱直齿齿轮6设计及校核 27

5.7.圆柱直齿齿轮6设计及校核 30

5.8.圆柱直齿齿轮8设计及校核 30

6 、 轴及轴承的设计及校核 34

6.1.齿轮轴1 34

6.2.惰轴 2 37

6.3.轴3 40

6.4.轴4 44

6.5.惰轴 5 47

6.6.轴 6 50

7 、行星齿轮设计及校核 51

7.1初步计算齿轮的主要参数

7.1.1计算变位系数 52

7.1.2 几何尺寸计算 53

7.1.3啮合要素验算 54

7.1.4齿轮强度验算 55

7.2.输出轴直径及轴承的确定: 66

8 、花键的设计及校核 66

8.1.输入轴上的的花键 66

8.2.轴三上的花键 67

8.3.轴四上的花键 67

8.4.输出轴上的花键 68

参考文献 69

翻译英文 70

翻译中文 76

致谢 81

…………

本文详细介绍了设计一台总装机功率为450KW的截割式滚筒液压牵引采煤机的过程,特别是其截割部的设计。采用了四级传动系统,包括直齿传动和行星齿轮减速器,创新地使用了两个惰轴系以满足强度和截割高度要求。此外,还涉及了齿轮、轴、轴承、花键等部件的设计与校核,旨在优化结构、节省材料和空间。

本文详细介绍了设计一台总装机功率为450KW的截割式滚筒液压牵引采煤机的过程,特别是其截割部的设计。采用了四级传动系统,包括直齿传动和行星齿轮减速器,创新地使用了两个惰轴系以满足强度和截割高度要求。此外,还涉及了齿轮、轴、轴承、花键等部件的设计与校核,旨在优化结构、节省材料和空间。

241

241

被折叠的 条评论

为什么被折叠?

被折叠的 条评论

为什么被折叠?