新人写帖子,仅供内部人员参照,使用大疆A型板,2006电机,c610电调,4s电池

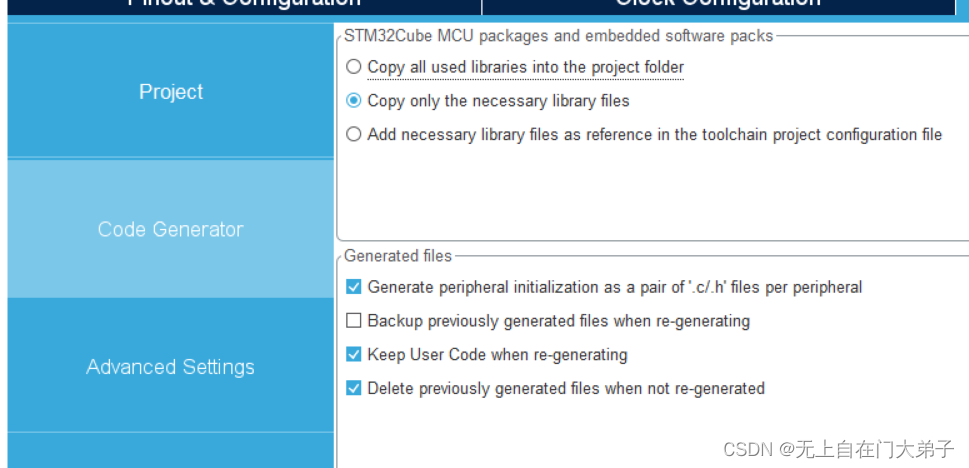

cubemx配置如图

基本配置

注意 HSE 设置为12MHz

配置can

注意将手动将PD0和PD1设置为can1

使用fifo0邮箱作为接收,所以使能RX0

配置工程名

即可生成

keil5代码部分

LSS_PID.c

#include "LSS_PID.h"

PID M3508_spid[8];

PID M3508_apid[8];

float abs_limit(float a, float ABS_MAX)

{

if(a > ABS_MAX)

a = ABS_MAX;

if(a < -ABS_MAX)

a = -ABS_MAX;

return a;

}

/**

三个用户自定义参数:

pp->Proportion比例

pp->Integral比例积分

pp->Derivative比例微分

**/

void PID_Position_Calc( PID *pp, float CurrentPoint, float NextPoint ) //位置式PID

{

pp->Error = NextPoint - CurrentPoint; //误差

pp->SumError += pp->Error; //积分项:误差累积

pp->DError = pp->Error - pp->LastError; //微分项:误差变化

pp->output = pp->Proportion * pp->Error + \

abs_limit(pp->Integral * pp->SumError, pp->Integralmax ) + \

pp->Derivative * pp->DError ; //pid输出

if(pp->output > pp->outputmax ) pp->output = pp->outputmax; //?

if(pp->output < - pp->outputmax ) pp->output = -pp->outputmax;//?

// pp->PrevError = pp->LastError; //上次误差保存

pp->LastError = pp->Error;//这次误差保存

}

void PID_Incremental_Calc( PID *pp, float CurrentPoint, float NextPoint ) //增量式PID

{

pp->Error = NextPoint - CurrentPoint;

pp->SumError += pp->Error;

pp->DError = pp->Error - pp->LastError;

pp->output += pp->Proportion * ( pp->Error - pp->LastError )+ \

abs_limit(pp->Integral * pp->Error, pp->Integralmax ) + \

pp->Derivative * ( pp->Error + pp->PrevError - 2*pp->LastError);

if(pp->output > pp->outputmax ) pp->output = pp->outputmax;

if(pp->output < - pp->outputmax ) pp->output = -pp->outputmax;

pp->PrevError = pp->LastError;

pp->LastError = pp->Error;

}

void PIDInit(PID *pp, float Kp , float Ki , float Kd , float outputmax, float Integralmax)

{

pp->Integralmax = Integralmax;//积分阈值?

pp->outputmax = outputmax;//输出阈值

pp->Proportion = Kp;

pp->Integral = Ki;

pp->Derivative = Kd;

pp->DError = pp->Error = pp->output = pp->LastError = pp->PrevError = 0;

}

LSS_PID.h

#ifndef __LSS_PID_H

#define __LSS_PID_H

typedef struct PID {

float Proportion; // Proportional Const

float Integral; // Integral Const

float Derivative; // Derivative Const

float PrevError; // Error[-2]

float LastError; // Error[-1]

float Error;

float DError;

float SumError; // Sums of Errors

float Integralmax;

float output;

float outputmax;

} PID;

extern PID M3508_spid[8];

extern PID M3508_apid[8];

float abs_limit(float a, float ABS_MAX);

void PID_Position_Calc( PID *pp, float CurrentPoint, float NextPoint);

void PID_Incremental_Calc( PID *pp, float CurrentPoint, float NextPoint);

void PIDInit(PID *pp, float Kp , float Ki , float Kd , float outputmax, float Integralmax);

#endif

LSS_3508.c

#include "LSS_3508.h"

//1-5 can1

//6-8 can2

//偏航角 ID 5

//俯仰角 ID 2

//翻转角 ID 3

//推进 ID 4

struct M3508_Fback_Inf m3508_fback_inf[1] =

{

{0x201,1,0,0,0,0,0,0,0,0,0,0,0,0,0,0,0,0,0},

};

//初始化m3508控制接口

void init_m3508_can(void)

{

CAN_FilterTypeDef hCAN_Filter;

//CAN1滤波器

hCAN_Filter.FilterBank = 0;

hCAN_Filter.SlaveStartFilterBank = 0;

hCAN_Filter.FilterMode = CAN_FILTERMODE_IDMASK;

hCAN_Filter.FilterScale = CAN_FILTERSCALE_32BIT;

hCAN_Filter.FilterIdHigh = 0;

hCAN_Filter.FilterIdLow = 0;

hCAN_Filter.FilterMaskIdHigh = 0;

hCAN_Filter.FilterMaskIdLow = 0;

hCAN_Filter.FilterFIFOAssignment = CAN_RX_FIFO0;

hCAN_Filter.FilterActivation = ENABLE;

if(HAL_CAN_ConfigFilter(&hcan1, &hCAN_Filter) != HAL_OK){

Error_Handler();

}

if(HAL_CAN_ActivateNotification(&hcan1, CAN_IT_RX_FIFO0_MSG_PENDING) != HAL_OK){

Error_Handler();

}

if(HAL_CAN_Start(&hcan1) != HAL_OK){

Error_Handler();

}

}

//执行时间5us

//发送m3508控制电流

void send_m3508_control_current(void)

{

uint8_t can_tx_buffer[8];

uint32_t CAN_TX_BOX0;

CAN_TxHeaderTypeDef hCAN_TxHeader;//CAN发送消息

hCAN_TxHeader.StdId = 0x200;

hCAN_TxHeader.IDE = CAN_ID_STD;

hCAN_TxHeader.RTR = CAN_RTR_DATA;

hCAN_TxHeader.DLC = 8;

can_tx_buffer[0] = m3508_fback_inf[0].control_current >> 8;

can_tx_buffer[1] = m3508_fback_inf[0].control_current;

can_tx_buffer[2] = 0;

can_tx_buffer[3] = 0;

can_tx_buffer[4] = 0;

can_tx_buffer[5] = 0;

can_tx_buffer[6] = 0;

can_tx_buffer[7] = 0;

HAL_CAN_AddTxMessage(&hcan1, &hCAN_TxHeader, can_tx_buffer, &CAN_TX_BOX0);

}

void HAL_CAN_RxFifo0MsgPendingCallback(CAN_HandleTypeDef *hcan)

{

uint8_t can_rx_buffer[8];

CAN_RxHeaderTypeDef hCAN_RxHeader;

if(hcan->Instance == hcan1.Instance)

{

HAL_CAN_GetRxMessage(hcan, CAN_RX_FIFO0, &hCAN_RxHeader, can_rx_buffer);

switch(hCAN_RxHeader.StdId)

{

case 0x201 :

{

m3508_fback_inf[0].angle = can_rx_buffer[0] << 8 | can_rx_buffer[1];//电机角度

m3508_fback_inf[0].speed = can_rx_buffer[2] << 8 | can_rx_buffer[3];//电机速度

m3508_fback_inf[0].torque_current = (can_rx_buffer[4] << 8 | can_rx_buffer[5]);//反馈转矩电流

// m3508_fback_inf[0].temperature = can_rx_buffer[6];//电机温度

if(m3508_fback_inf[0].frist_flag == 1)//上电标志为1

{

if(m3508_fback_inf[0].frist_cnt ++ <= 150)//上电计数

{

m3508_fback_inf[0].fris_angle = m3508_fback_inf[0].angle;//上电角度等于电机角度值

m3508_fback_inf[0].frist_flag = 0;//上电标志为0

}

if(m3508_fback_inf[0].angle > 4096)//bug 初始值大于4096 会轮转一圈

m3508_fback_inf[0].round_cnt = 1;

}

else

{

if(m3508_fback_inf[0].angle - m3508_fback_inf[0].last_angle > 4096)//电机角度 - 上一次电机角度

m3508_fback_inf[0].round_cnt --;//电机旋转圈数自减

else if(m3508_fback_inf[0].angle - m3508_fback_inf[0].last_angle < -4096)

m3508_fback_inf[0].round_cnt ++;//电机旋转圈数自加

m3508_fback_inf[0].last_angle = m3508_fback_inf[0].angle;//上一次电机角度等于电机角度

m3508_fback_inf[0].total_angle = m3508_fback_inf[0].round_cnt * 8192 + m3508_fback_inf[0].angle - m3508_fback_inf[0].fris_angle;//电机总转角度

}

}break;

}

}

}

/***输入角度输出脉冲数****/

int32_t m3508_Ang2Cnt(float ang)

{

int32_t cnt = CNT_PER_ROUND_OUT / 360.0f * ang;

return cnt;

}

/****输入脉冲数输出角度****/

float m3508_Cnt2Ang(int32_t cnt)

{

return (float) ((cnt * 360.0f) / CNT_PER_ROUND_OUT);

}

LSS_3508.h

#ifndef _LSS_3508_H_

#define _LSS_3508_H_

#include "stm32f4xx_hal.h"

#include "can.h"

#define CNT_PER_ROUND 8192 //外转子转一圈的脉冲数

#define REDUCTION_RATIO 19.0f //减速比

#define CNT_PER_ROUND_OUT (CNT_PER_ROUND * REDUCTION_RATIO) //电机轴转一圈的脉冲数

#define CNT_PER_ROUND1 8192 //外转子转一圈的脉冲数

#define REDUCTION_RATIO1 36.0f //减速比

#define CNT_PER_ROUND_OUT1 (CNT_PER_ROUND1 * REDUCTION_RATIO1) //电机轴转一圈的脉冲数

#define MIN(a,b) (((a)<(b))?(a):(b))

#define MAX(a,b) (((a)>(b))?(a):(b))

#define CLAMP(x, lower, upper) (MIN(upper, MAX(x, lower)))

#define lift_max 100

#define lift_min 0

#define close_max 90

#define close_min -90

struct M3508_Fback_Inf

{

uint32_t id;//电机id

uint8_t frist_flag;//上电标志

uint16_t frist_cnt;//上电计数

int16_t fris_angle;//上电角度

int16_t angle;//电机角度

int16_t last_angle;//上一次电机角度

int32_t round_cnt;//电机旋转圈数

int64_t total_angle;//电机总转角度

int64_t set_angle;//设置电机目标角度

uint8_t speed_cnt_time;

uint8_t speed_cnt;

int32_t last_total_angle[2];//上一次电机总转角度

int16_t speed;//电机速度

int16_t torque_current;//反馈转矩电流

int16_t torque_rated;//设定转矩电流

int16_t set_speed;//设置速度

int16_t control_current;//电机控制电流

uint8_t temperature;//电机温度

};

extern struct M3508_Fback_Inf m3508_fback_inf[];

//初始化m3508控制接口

void init_m3508_can(void);

//发送m3508控制电流

void send_m3508_control_current(void);

/***输入角度输出脉冲数****/

int32_t m3508_Ang2Cnt(float ang);

/****输入脉冲数输出角度****/

float m3508_Cnt2Ang(int32_t cnt);

#endif

main.c

/* USER CODE BEGIN Header */

/**

******************************************************************************

* @file : main.c

* @brief : Main program body

******************************************************************************

* @attention

*

* Copyright (c) 2022 STMicroelectronics.

* All rights reserved.

*

* This software is licensed under terms that can be found in the LICENSE file

* in the root directory of this software component.

* If no LICENSE file comes with this software, it is provided AS-IS.

*

******************************************************************************

*/

/* USER CODE END Header */

/* Includes ------------------------------------------------------------------*/

#include "main.h"

#include "can.h"

#include "gpio.h"

/* Private includes ----------------------------------------------------------*/

/* USER CODE BEGIN Includes */

#include "LRJ_3508.h"

#include "LRJ_PID.h"

/* USER CODE END Includes */

/* Private typedef -----------------------------------------------------------*/

/* USER CODE BEGIN PTD */

int16_t ref_speed,inf_speed;

int16_t pid_output;

/* USER CODE END PTD */

/* Private define ------------------------------------------------------------*/

/* USER CODE BEGIN PD */

/* USER CODE END PD */

/* Private macro -------------------------------------------------------------*/

/* USER CODE BEGIN PM */

/* USER CODE END PM */

/* Private variables ---------------------------------------------------------*/

/* USER CODE BEGIN PV */

/* USER CODE END PV */

/* Private function prototypes -----------------------------------------------*/

void SystemClock_Config(void);

/* USER CODE BEGIN PFP */

/* USER CODE END PFP */

/* Private user code ---------------------------------------------------------*/

/* USER CODE BEGIN 0 */

/* USER CODE END 0 */

/**

* @brief The application entry point.

* @retval int

*/

int main(void)

{

/* USER CODE BEGIN 1 */

/* USER CODE END 1 */

/* MCU Configuration--------------------------------------------------------*/

/* Reset of all peripherals, Initializes the Flash interface and the Systick. */

HAL_Init();

/* USER CODE BEGIN Init */

/* USER CODE END Init */

/* Configure the system clock */

SystemClock_Config();

/* USER CODE BEGIN SysInit */

/* USER CODE END SysInit */

/* Initialize all configured peripherals */

MX_GPIO_Init();

MX_CAN1_Init();

/* USER CODE BEGIN 2 */

//ref_speed = 1000;

init_m3508_can();//开启过滤器

PIDInit(&M3508_spid[0],5,0,0,15000,15000);//速度环设置和限幅 spid:15 0.5 0

/* USER CODE END 2 */

/* Infinite loop */

/* USER CODE BEGIN WHILE */

while (1)

{

PID_Incremental_Calc(&M3508_spid[0], m3508_fback_inf[0].speed, ref_speed);//速度环

m3508_fback_inf[0].control_current = M3508_spid[0].output;

send_m3508_control_current();

HAL_Delay(5);//有bug必须搞个5ms延时,或者开个定时器中断丢中断里头

/* USER CODE END WHILE */

/* USER CODE BEGIN 3 */

}

/* USER CODE END 3 */

}

/**

* @brief System Clock Configuration

* @retval None

*/

void SystemClock_Config(void)

{

RCC_OscInitTypeDef RCC_OscInitStruct = {0};

RCC_ClkInitTypeDef RCC_ClkInitStruct = {0};

/** Configure the main internal regulator output voltage

*/

__HAL_RCC_PWR_CLK_ENABLE();

__HAL_PWR_VOLTAGESCALING_CONFIG(PWR_REGULATOR_VOLTAGE_SCALE1);

/** Initializes the RCC Oscillators according to the specified parameters

* in the RCC_OscInitTypeDef structure.

*/

RCC_OscInitStruct.OscillatorType = RCC_OSCILLATORTYPE_HSE;

RCC_OscInitStruct.HSEState = RCC_HSE_ON;

RCC_OscInitStruct.PLL.PLLState = RCC_PLL_ON;

RCC_OscInitStruct.PLL.PLLSource = RCC_PLLSOURCE_HSE;

RCC_OscInitStruct.PLL.PLLM = 6;

RCC_OscInitStruct.PLL.PLLN = 180;

RCC_OscInitStruct.PLL.PLLP = RCC_PLLP_DIV2;

RCC_OscInitStruct.PLL.PLLQ = 4;

if (HAL_RCC_OscConfig(&RCC_OscInitStruct) != HAL_OK)

{

Error_Handler();

}

/** Activate the Over-Drive mode

*/

if (HAL_PWREx_EnableOverDrive() != HAL_OK)

{

Error_Handler();

}

/** Initializes the CPU, AHB and APB buses clocks

*/

RCC_ClkInitStruct.ClockType = RCC_CLOCKTYPE_HCLK|RCC_CLOCKTYPE_SYSCLK

|RCC_CLOCKTYPE_PCLK1|RCC_CLOCKTYPE_PCLK2;

RCC_ClkInitStruct.SYSCLKSource = RCC_SYSCLKSOURCE_PLLCLK;

RCC_ClkInitStruct.AHBCLKDivider = RCC_SYSCLK_DIV1;

RCC_ClkInitStruct.APB1CLKDivider = RCC_HCLK_DIV4;

RCC_ClkInitStruct.APB2CLKDivider = RCC_HCLK_DIV2;

if (HAL_RCC_ClockConfig(&RCC_ClkInitStruct, FLASH_LATENCY_5) != HAL_OK)

{

Error_Handler();

}

}

/* USER CODE BEGIN 4 */

/* USER CODE END 4 */

/**

* @brief This function is executed in case of error occurrence.

* @retval None

*/

void Error_Handler(void)

{

/* USER CODE BEGIN Error_Handler_Debug */

/* User can add his own implementation to report the HAL error return state */

__disable_irq();

while (1)

{

}

/* USER CODE END Error_Handler_Debug */

}

#ifdef USE_FULL_ASSERT

/**

* @brief Reports the name of the source file and the source line number

* where the assert_param error has occurred.

* @param file: pointer to the source file name

* @param line: assert_param error line source number

* @retval None

*/

void assert_failed(uint8_t *file, uint32_t line)

{

/* USER CODE BEGIN 6 */

/* User can add his own implementation to report the file name and line number,

ex: printf("Wrong parameters value: file %s on line %d\r\n", file, line) */

/* USER CODE END 6 */

}

#endif /* USE_FULL_ASSERT */

结束,挺简单的,有代码直接往上套用即可,不需要配置其他乱七八糟的东西,为了凑字数,随便唠点开发事故吧。为什么文章标题叫做A板杀手,因为吾有一友,拿4s电池怼到12v输出接口,霎时间,烟雾弥漫在我的工位上..........顾不上手上窜着的火花,立马将电池从分电板上拔下,索性,A版的防反接保护起作用了,要不然就不只是烧两根电线这么简单的事了。一阵喧嚣过后,我那兄弟手还不断颤抖,嘴里不停念叨着,完了完了,昨天烧电机,今天烧板子(我当时绷不住了)。那兄弟接反这个A板的电源,倒是也情有可原,之前他用的都是c板,a板没怎么用过,c板上的xt30都是相互导通的,没有什么输入端输出端之分,相当于集成了一个分电板,所以也没这么多讲究,这原罪还是得怪在DJI头上,搞这么多的坑钱东西在板子上,A板和C板在差异化上又这么不明显,就像是A板是初代,C板才是改进过的版本一样。好在还有个保护电路的设计,这一点确实不错。好了就说这么些了,下一篇我就跟新速度环和位置环的串级PID,敬请期待

被折叠的 条评论

为什么被折叠?

被折叠的 条评论

为什么被折叠?