When doing on-site services or training, I am often asked: When should one use the derivative control mode of a PID controller? Although there is no black & white division between when to use it or not, I have a few guidelines that should help your decision. But let’s take a step back first and review the derivative control mode and its role in a PID controller.

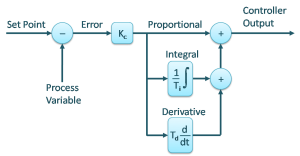

Figure 1. PID Controller

What is Derivative?

You can think of derivative control as a crude prediction of the error in future, based on the current slope of the error. How far into the future? That’s what the derivative time (Td) is for. It is the prediction horizon. (Derivative control actually uses extrapolation, not prediction. But hey, we all understand how prediction works, so I’ll just go with that.) Once the derivative mode has predicted the future error, it adds an additional control action equal to Controller Gain * Future Error.

For example, if the error changes at a rate of 2% per minute, and the derivative time Td = 3 minutes, the predicted error is 6%. If the Controller Gain, Kc = 0.2, then the derivative control mode will add an additional 0.2 * 6% = 1.2% to the controller output.

You don’t Absolutely Need Derivative

The first point to consider when thinking about using derivative is that a PID control loop will work just fine without the derivative control mode. In fact, the overwhelming majority of control loops in industry use only the proportional and integral control modes. Proportional gives the control loop an immediate response to an error, and the integral mode eliminates the error in the longer term. Hence – no derivative is needed.

Why Use Derivative

The derivative control mode gives a controller additional control action when the error changes consistently. It also makes the loop more stable (up to a point) which allows using a higher controller gain and a faster integral (shorter integral time or higher integral gain).

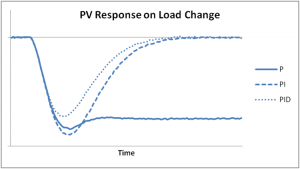

These have the effect of reducing the maximum deviation of process variable from set point if the process receives and external disturbance. For a typical temperature control loop, you can expect a 20% reduction in the maximum deviation. Figure 2 shows how a loop with derivative (PID) control recovers quicker from a disturbance with less deviation than a loop with P or PI control.

Figure 2. P versus PI versus PID control.

Obviously you don’t want to use derivative to speed up a loop if the control objective is slow response, like a surge tank, for example. But for loops where fast response is the objective, derivative could help. But do read on for information on when not to use derivative.

Noisy PV

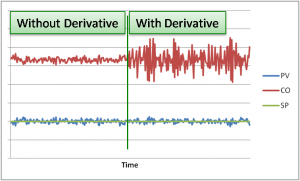

Using the derivative control mode is a bad idea when the process variable (PV) has a lot of noise on it. ‘Noise’ is small, random, rapid changes in the PV, and consequently rapid changes in the error. Because the derivative mode extrapolates the current slope of the error, it is highly affected by noise (Figure 3). You could try to filter the PV so you can use derivative, as long as your filter time constant is shorter than 1/5 of your derivative time.

Figure 3. Effect of Noise on Derivative.

Process Dynamics

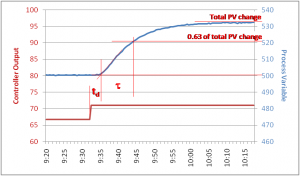

On dead-time dominant processes, PID control does not always work better than PI control (it depends on which tuning method you use). If the time constant (tau) is equal to or longer than the dead time (td), like in Figure 4, PID control easily outperforms PI control.

Figure 4. Process Dynamics.

Temperature and Level Loops

Temperature control loops normally have smooth measurements and long time constants. The process variable of a temperature loop tends to move in the same direction for a long time, so its slope can be used for predicting future error. So temperature loops are ideal candidates for using derivative control – if needed. Level measurements can be very noisy on boiling liquids or gas separation processes. However, if the level measurement is smooth, level control loops also lend themselves very well to using derivative control (except for surge tanks and averaging level control where you don’t need the speed).

Flow Control Loops

Flow control loops tend to have noisy PVs (depending on the flow measurement technology used). They also tend to have short time constants. And they normally act quite fast already, so speed is not an issue. These factors all make flow control loops poor candidates for using derivative control.

Pressure Control Loops

Pressure control loops come in two flavors: liquid and gas. Liquid pressure behaves very much like flow loops, so derivative should not be used. Gas pressure loops behave more like temperature loops (some even behave like level loops / integrating processes), making them good candidates for using derivative control.

Final Words

Derivative control adds another dimension of complexity to control loops. It does have its benefits, but only in special cases. If a loop does not absolutely need derivative control, don’t bother with it. However, if you have a lag-dominant loop with a smooth process variable that needs every bit of speed it can get, go for the derivative.

To learn more about controllers and tuning, contact OptiControls to for on-site process control training.

Stay tuned!

Jacques Smuts – Author of the book Process Control for Practitioners

![]() Posted in 3. PID Controllers |

Posted in 3. PID Controllers | ![]() Tags: Controller Tuning, Derivative Control

Tags: Controller Tuning, Derivative Control

6 Responses to “Derivative Control Explained”

-

Garcier LaCamppiello:

I used this as a refresher-review and found it very helpful. You have done a fine job at describing the derivative control mode and I recommend it to all readers. I am an Instrumentation Technician formerly with Alyeska Pipeline Service Co., Alaska, retired but still functional.

Thank you,

-

abdul wahab:

nice, i am very happy to learn this

-

Sivasankar:

Really useful…since im an inst engineer, having long time doubt about usage of derivative control…i searched lot n didn’t convince any answers…but here i really got wat i wanted..thanks a lot.

-

Osama:

Very Helpful. Explanation is clear and really one of the best posts on this subject. Good job

Thanks a lot -

arch:

Really great write ups…thanks so much!

If you had a noisy PV that you were only using PI control on, could you use filtering to smooth out the noise on the PV, and then incorporate some derivative control to regain some or all of the loss in loop responsivity?

-

Arch: Not really. Noise affects the derivative control mode much more than it affects proportional control. So once you add a bit of derivative to regain performance, you will have to increase the amount of filtering to smooth down the controller output. That will probably negate the use of derivative.

PID控制器:导数控制详解

PID控制器:导数控制详解

本文详细解释了PID控制器中导数控制模式的作用及应用条件。导数控制能够预测误差变化并加速控制响应,尤其适用于长滞后过程。然而,在过程变量存在大量噪声或不需要快速响应的情况下,使用导数控制可能弊大于利。文章还讨论了不同类型控制回路(如温度、液位、流量和压力控制)在使用导数控制时的考量。

本文详细解释了PID控制器中导数控制模式的作用及应用条件。导数控制能够预测误差变化并加速控制响应,尤其适用于长滞后过程。然而,在过程变量存在大量噪声或不需要快速响应的情况下,使用导数控制可能弊大于利。文章还讨论了不同类型控制回路(如温度、液位、流量和压力控制)在使用导数控制时的考量。

1544

1544

被折叠的 条评论

为什么被折叠?

被折叠的 条评论

为什么被折叠?