![]() Warehouse Management with Lean WM

Warehouse Management with Lean WM

Use

When you implement the Warehouse Management System (WMS), you manage goods movements and stock changes in the warehouse at storage bin level. However, if you implement Lean WM, inventory management takes place solely at storage location level. The system does not update the stock data at storage bin level using the quants.

当你实施WMS仓库管理系统时,你的仓库是在仓位级别进行货物移动和库存改变的。然而,如果你实施了Lean WM,库存管理只单独发生在库存地点级别。系统不会在仓位级别上使用份对库存数据进行更新。

You use Lean WM solely for processing goods receipts and goods issues. Using Lean WM, you process the warehouse movements in basically the same way as if using the Warehouse Management System: you work with deliveries, and you create transfer orders for these deliveries. These transfer orders serve as pick lists (see also Using the Transfer Order as a Pick List in Lean WM). We recommend that you implement Lean WM if you wish to pick deliveries in a warehouse that you are not managing using WMS.

你可以使用Lean WM单独地处理发货或及收货。使用Lean WM,你处理货物移动基本上跟WMS一样:处理交货,并对这些交货创建转储订单。这些转储订单可作为拣配清单来使用。如果你希望在仓库中对交货单进行拣配,但又不使用WMS进行管理的话,我们推荐你实施Lean WM。

The use of transfer orders in Lean WM provides the following advantages:

- You can reprint transfer orders at any time.

在任何时候你都可能打印转储订单。 - You can split transfer orders and thus distribute the workload better among the staff in your warehouse.

你可以对转储订单进行拆分,从而可以在你的仓管人员之间更好地分配工作量。 - You can pass on the transfer order target data and the names of those who process transfer orders to the HR application component, where this data can be used to calculate incentive wage.

If you do no wish to update stocks in your fixed bin warehouse at storage bin level, Lean WM provides you with the option of using the advantages of warehouse management through transfer orders in the same way as warehouse management using the WMS.

If you are already using the standard WM system, we recommend that you implement Lean WM in a further warehouse where no updating of stocks at storage bin level is necessary. In this way, you ensure that the processes for warehouse management are uniform in all warehouses.

Since Lean WM does not update stocks at storage bin level, you can display the stock quantities solely in Inventory Management (IM) and not with the stock overview function in WM. Also, you cannot process possible stock differences that occur in the warehouse using Lean WM, only using Inventory Management (MM-IM):

Prerequisites

You can only implement Lean WM in a fixed bin warehouse; random storage is not possible.

你只能在固定仓位的仓库上实施Lean WM,而不能在随意仓储的仓库上进行。

Before you can implement Lean WM, you need to make the following configuration changes in Customizing:

- Assign a (newly defined) storage location to a warehouse number.

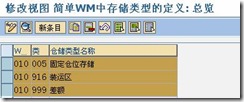

分配或新定义一个库存地点给一个仓库号 - Set up at least two storage types:

建立至少2个存储类型:

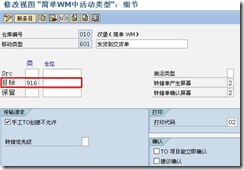

- a picking storage type as the source storage type

一个拣配存储类型作为源发存储类型(固定仓位005) - A shipping area as the destination storage type for deliveries

一个装运区作为交货的目标存储类型(装运区916)

- a picking storage type as the source storage type

For more information, refer to the section Setting up Lean-WM.

Use

In order to be able to use Lean WM in your warehouse, you must first execute the following settings in Customizing for Shipping.

Procedure

In Customizing for Shipping, choose Picking ® Lean-WM.

| Customizing Activity | Path | What You Should Know |

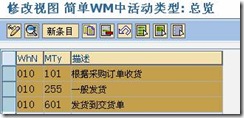

| Defining control parameters and number ranges for the warehouse number | ® Define control parameters and number ranges for the warehouse number | In the SAP standard version, warehouse number 010 is preset for Lean WM. We recommend that you always use warehouse number 010 as a warehouse to copy when you implement Lean WM. |

| Defining storage type for Lean WM | ® Define storage type | In the SAP standard version, different examples of Lean WM storage types are preset in warehouse number 010. We recommend setting up, as a minimum, the following storage types:

|

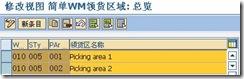

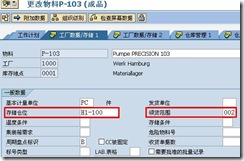

| Defining the picking area | ® Define picking areas | Lean WM is a prerequisite for implementation of picking areas. In the material master, a picking area must be assigned to the material in the view Plant data / Storage 1. In the SAP standard version, two picking areas are preset. |

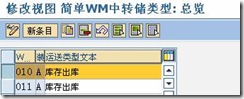

| Defining transfer types | ® Define transfer types | In the SAP standard version, transfer type A (outbound delivery) is preset for warehouse number 010 (Lean WM). We recommend keeping this transfer type. |

| Defining movement types | ® Define movement types | The movement type for Lean WM supplies the information that is required for inbound and outbound deliveries.

Movement types 101, 601, and 255 are preset for Lean WM. We recommend keeping these movement types. |

| Defining difference indicator | ® Define difference indicator | Via the difference indicator, you can classify stock differences. This indicator is used in Lean WM for evaluation purposes only. In the SAP standard version, difference indicators for Lean WM are stored in warehouse number 010. We recommend using difference indicator " " (blank) only. |

| Defining print control | ® Define print control | For further information, refer to the Implementation Guide (IMG) for Shipping under the path Picking ® Lean-WM ® Define print control. |

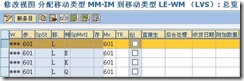

| Synchronizing movement types between Inventory Management (MM-IM) and the Warehouse Management System (Lean WM) | ® Interface Inventory Management | In the SAP standard version, all the relevant movement types are preset. We recommend working with the standard version. |

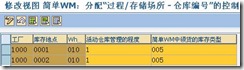

| Defining degree of activation for Warehouse Management (selection between Lean WM and full WM) | ® Control Plant / Storage Location / Warehouse Number Assignment | Decide which feature you want to implement for Warehouse Management and define the control for assignment Plant / Storage Location / Warehouse Number. In the SAP standard version, Lean WM is preset with activation degree 1 in warehouse number 010. |

![]() Using a Transfer Order as a Pick Order in Lean WM

Using a Transfer Order as a Pick Order in Lean WM

Purpose

In Lean-WM, you create transfer orders (TO) for deliveries to pick stock from fixed bins in the warehouse that are not managed by the WM system.

使用Lean-WM,你可以在没有WMS管理的情况下,为交货单创建转储订单来从固定仓位上拣配库存。

Transfer orders created with Lean WM instead of normal WM have the following characteristics:

- Confirmation of transfer orders is not required.

不需要对转储订单进行确认。 - Stock differences are reported to IM for processing. Handling differences is not possible in WM.

库存差异提报给IM来进行处理,而不在WM中处理。 - You can transmit Lean WM transfer order data to external systems.

你可以传输Lean WM的转储订单数据到外部系统。 - Recording performance data, such as assignment to a picker, return confirmation of actual times or determining planned times is possible for this type of TO.

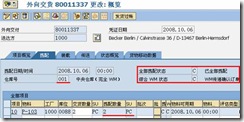

- If a transfer order has been created, subsequent changes to the delivery can be made in the Pick Quantity field. This is not possible in standard WM.

如果转储订单已经创建,可以更改后续交货单的拣配数量字段,然而这在标准WM中是不可能的。

Prerequisites

You have set up Lean WM in your SAP System. For more information, refer to Setting up Lean WM. See Logistics Execution ® Shipping ® Picking ® Lean WM in Customizing for a description of the different activities.

Process Flow

Generally, the processes used in Lean WM are similar to those in normal WM. There are deliveries and transfer orders are created for the deliveries. However, with Lean WM, it is much easier to create the transfer order.

一般地,使用Lean WM的步骤跟标准WM是相似的:都有交货和对交货创建转储订单。然而,对于Lean WM来讲,创建转储订单会更简单得多。

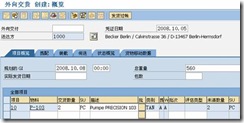

- Create a delivery as the prerequisite for the transfer order.

创建一个交货作为转储订单的先决条件。

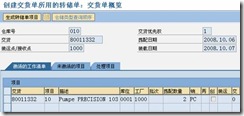

- Create a transfer order for the delivery.

为交货创建一个转储订单。

- Post the goods issue.

发货过帐。

被折叠的 条评论

为什么被折叠?

被折叠的 条评论

为什么被折叠?