The Oracle Order Management Suite consists of:

- Oracle Order Management

- Oracle Shipping Execution

- Basic Pricing

Order Management implementation involves several phases, including setting up other integrated applications, which include Oracle General Ledger, Oracle Receivables, and Oracle Inventory. Some setup steps are optional, depending on whether you have the integrating applications installed and whether you use the associated feature. For example, if your business supports drop shipments, you should also set up Oracle Purchasing. If you sell models and kits, set up Oracle Bills of Material and Oracle

Configurator.

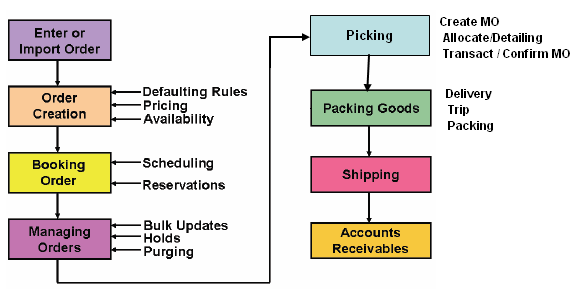

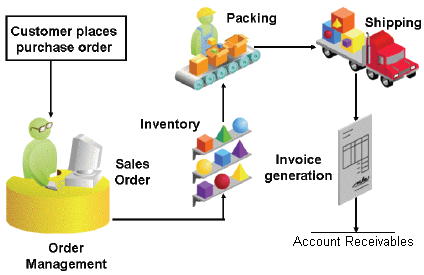

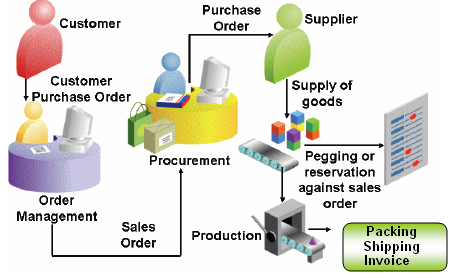

1. A detailed process of order to cash cycle is shown below

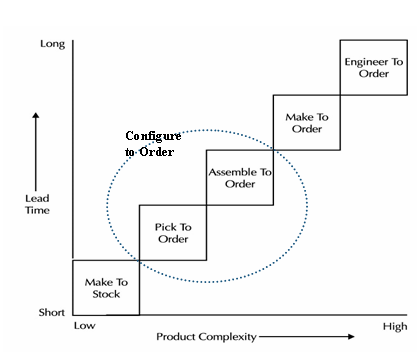

2. Oracle Manufacturing and Supply Chain Applications enable customers to operate using various supply-chain stocking strategies. The term stocking strategy denotes a process that identifies and maintains the optimum level of your bills of material at which you should maintain your inventory, so that your inventory investment is a minimum. For example, in the ship building industry, you would not keep any inventory, whereas you would have to keep inventory in your retail outlets if you were selling shoes.

The amount of time a customer is willing to wait to buy a product (delivery lead-time) is a very important determinant of the supply-chain stocking strategy. As the delivery lead-time decreases, the finished goods inventory moves closer to the consumption point. To a certain extent, product complexity can also be an important determinant of a supply-chain stocking strategy. Below Figure shows the typical position of each of these strategies in a lead-time–product complexity graph.

- Ship from stock (MTS make to stock) : You have sufficient inventory items in stock and the order is directly fullfilled from inventory. In an MTS environment, you produce your products and stock them in anticipation of customer orders. A good forecasting system is very important to this environment because most of the material and capacity planning is done using forecasts rather than actual demand. Examples include stereo systems and television sets.

- Make to order: After entering the sales order the schedule and planning process creates a job to fulfill the order. Once the job is completed the on hand of that particular customer ordered item is increased in the inventory and later is shipped to the customer.

Standard products are designed and published in catalogs. The actual product is built on receipt of the customer order. Customers might be able to choose certain characteristics optionally. An example of this would be machine building. Each customer order may have an associated project to manage the production and delivery schedule.

- Configure to order(ATO, PTO, CTO):

Pick-To-Order (PTO)

Under this strategy, a variety of shippable components are stocked. Customers order “kits” or collections of these parts under a single item number; kits can be either predefined or configured by the customer during the order entry process. The components of the kit are picked and shipped from stock; there is no additional value added after the customer order, other than perhaps packing the components for shipment. A computer system (including the central processing unit, monitor, and printer) is an example of this.

Assemble-To-Order (ATO)

These are also standard products and are often configured by customers. You don’t wait until the order is received to build an ATO product. Subassemblies are manufactured prior to receiving the order and when the order is received, the subassemblies are assembled to make the finished product. Automobiles and computers are examples of this type of production.

Configure to order(CTO)

It includes both the ATO and PTO.Similar to the above processes but here the customer has the facility of configuring the items on the basis of its requirement.

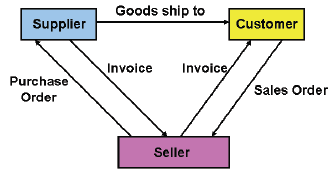

- Dropship to customer: Drop shipments is a method of fullfilling sales order by selling products without the order taker handling, stocking, or delivering them. The seller buys a product and the supplier ships the product directly to the seller's customer. Drop shipments are done because of the following reasons

Customer requires an item that is not normally stocked

Customer requires a large quantity of the item which is not available with you

It is more economical when the supplier ships directly to the customerIn drop ship cycle, the seller receives a sales order from the customer and sends a purchase order to the supplier. The supplier ships directly to the customer. The seller receives an invoice from the supplier and sends an invoice to the customer. The seller receives an invoice from the supplier and sends an invoice to the customer.

- Internal Order: When the material required in one organization is available in another org we create an internal requisition and oracle converts that to a SO in the org where the item is available. The complete process is as shown below.

- Back to Back order: It involves the concept of soft-pegging.

Important setups

Reference: http://www.oracleug.com/user-guide/order-management/introduction-om

308

308

被折叠的 条评论

为什么被折叠?

被折叠的 条评论

为什么被折叠?