之前在STM32F103上移植过PMBus从机程序,这次要设计服务器数字电源,PMBus不可少。这次使用的是TI的TMS320F280049C系列,以TI的TIDA-010062设计参考为基础,结合技术手册熟悉相关外设的配置后(最主要就是EPWM、ADC及CMPSS模块),也趁硬件PCB还没有完成,PFC+LLC还不能调试,就开始验证PMBus这一块。正好手头上有一块之前学习BUCK数字电路购买的LAUNCHXL-F280049C Development Kit,就拿它做试验。我还是使用原来的TI参考样例,下载地址如下:

http://www.ti.com/lit/zip/SPRABJ6

我的测试项目截图如下:

其中最主要是用到PMBusSlave.c,PMBusSlave.h,PMBus.h及main.c文件,主程序如下:

//#############################################################################

//

// FILE: i2c_ex1_slave.c

//

// TITLE: I2C Example Slave.

//

//! \addtogroup bitfield_example_list

//! <h1>I2C master slave communication using bit-field and without FIFO </h1>

//!

//! This program shows how to use I2CA in slave configuration.

//! This example uses I2C interrupts and doesn't use FIFO.

//!

//! \b Requires two Control Cards - one configured as Master and other as Slave \n

//! \b Master will run the binary generated from "i2c_ex1_master.projectspec" \n

//! \b Slave will run the binary generated from "i2c_ex1_slave.projectspec" \n

//! \b External \b Connections on Control Cards should be made as shown below \n

//! --------------------------------------------------------------

//! Signal | I2CA on Board1 | I2CA on Board 2

//! -----------------------------------------------------------------

//! SCL | GPIO_PIN_SCLA | GPIO_PIN_SCLA

//! SDA | GPIO_PIN_SDAA | GPIO_PIN_SDAA

//! GND | GND | GND

//! ---------------------------------------------------------------

//!

//! \b Watch \b Variables in memory window\n

//! - \b I2CA_TXdata

//! - \b I2CA_RXdata

//!

//

//#############################################################################

// $Copyright:

// Copyright (C) 2024 Texas Instruments Incorporated - http://www.ti.com/

//

// Redistribution and use in source and binary forms, with or without

// modification, are permitted provided that the following conditions

// are met:

//

// Redistributions of source code must retain the above copyright

// notice, this list of conditions and the following disclaimer.

//

// Redistributions in binary form must reproduce the above copyright

// notice, this list of conditions and the following disclaimer in the

// documentation and/or other materials provided with the

// distribution.

//

// Neither the name of Texas Instruments Incorporated nor the names of

// its contributors may be used to endorse or promote products derived

// from this software without specific prior written permission.

//

// THIS SOFTWARE IS PROVIDED BY THE COPYRIGHT HOLDERS AND CONTRIBUTORS

// "AS IS" AND ANY EXPRESS OR IMPLIED WARRANTIES, INCLUDING, BUT NOT

// LIMITED TO, THE IMPLIED WARRANTIES OF MERCHANTABILITY AND FITNESS FOR

// A PARTICULAR PURPOSE ARE DISCLAIMED. IN NO EVENT SHALL THE COPYRIGHT

// OWNER OR CONTRIBUTORS BE LIABLE FOR ANY DIRECT, INDIRECT, INCIDENTAL,

// SPECIAL, EXEMPLARY, OR CONSEQUENTIAL DAMAGES (INCLUDING, BUT NOT

// LIMITED TO, PROCUREMENT OF SUBSTITUTE GOODS OR SERVICES; LOSS OF USE,

// DATA, OR PROFITS; OR BUSINESS INTERRUPTION) HOWEVER CAUSED AND ON ANY

// THEORY OF LIABILITY, WHETHER IN CONTRACT, STRICT LIABILITY, OR TORT

// (INCLUDING NEGLIGENCE OR OTHERWISE) ARISING IN ANY WAY OUT OF THE USE

// OF THIS SOFTWARE, EVEN IF ADVISED OF THE POSSIBILITY OF SUCH DAMAGE.

// $

//#############################################################################

//

// Included Files

//

#include "f28x_project.h"

#include "PMBusSlave.h"

#include "sci.h"

#include "watchdog.h"

#define RUN_LED_GPIO 23

#define RUN_LED_PIN_CONFIG GPIO_23_GPIO23

#define RUN_LED_PRESCALE ((uint16_t)5)

void HAL_setupRunLed(void)

{

//

// GPIO23 requires additional configuration on F28004x

//

#if(RUN_LED_GPIO == 23)

//GPIO_setAnalogMode(RUN_LED_GPIO, GPIO_ANALOG_DISABLED);

#endif

//GPIO_setDirectionMode(RUN_LED_GPIO, GPIO_DIR_MODE_OUT);

//GPIO_setPinConfig(RUN_LED_PIN_CONFIG);

//GPIO_SetupPinMux(RUN_LED_GPIO, GPIO_MUX_CPU1, 0);

//GPIO_SetupPinOptions(RUN_LED_GPIO, GPIO_PUSHPULL, GPIO_PULLUP);

GPIO_SetupPinMux(RUN_LED_GPIO, GPIO_MUX_CPU1, 0);

GPIO_SetupPinOptions(RUN_LED_GPIO, GPIO_OUTPUT, GPIO_PUSHPULL);

}

void LED_Run(void)

{

GPIO_WritePin(RUN_LED_GPIO, 0);

DELAY_US(500000);

GPIO_WritePin(RUN_LED_GPIO, 1);

DELAY_US(500000);

}

void main(void)

{

//

// Initialize System Control: PLL, WatchDog, enable Peripheral Clocks

//

InitSysCtrl();

//

// Initialize GPIO

//

InitGpio();

//

// Initialize the PIE control registers to their default state.

// The default state is all PIE interrupts disabled and flags are cleared.

//

InitPieCtrl();

//

// Disable CPU interrupts and clear all CPU interrupt flags

//

IER = 0x0000;

IFR = 0x0000;

//

// Initialize the PIE vector table with pointers to the shell Interrupt Service Routines (ISR)

//

InitPieVectTable();

// Initialize I2C Module

PMBusSlave_Init(I2C_SLAVE_ADDR);

HAL_setupRunLed();

Watchdog_Init();

SCI_FIFO_Init();

while (1)

{

PMBus_Error_Detect();

ServiceDog();

//SCI_Run();

}

}

主要是LED配置(系统运行提示)、PMBus从机初始化,看门狗和SCI模块可忽略。主要看下PMBusSlave_Init函数的配置底层I2C驱动(TI原来提供的模板代码我没有注释,实际用到的GPIO分别是:SDA: GPIO35, SCL: GPIO37),PMBusSlave_Init函数和I2CSlave_Init函数代码分别如下:

PMBusSlave_Init函数:

/***************************************************************************//**

* @brief Configure the C2000 device as a PMBus slave.

* @param PMBusSlave_DeviceAddress The slave device's own address.

* @return None

******************************************************************************/

#warn "Change the GPIOs used for Alert and Control lines to match the desired GPIOs for the application."

void PMBusSlave_Init(unsigned char PMBusSlave_DeviceAddress)

{

//GPIO配置我保持了原来的,没有注释,但实际上用的的GPIO35和GPIO37

StatusRegs.StatusWord.all = 0; //Clear status bits for the status registers we are using

StatusRegs.StatusCml.all = 0;

// Control Line functionality GPIO0

GpioCtrlRegs.GPAPUD.bit.GPIO0 = 0; //Enable pullup on GPIO0

GpioDataRegs.GPASET.bit.GPIO0 = 1; //Drive line high

GpioCtrlRegs.GPAQSEL1.bit.GPIO0 = 0; //SYNC to SYSCLKOUT

GpioCtrlRegs.GPACTRL.bit.QUALPRD0 = 0;//no qualification (SYNC to SYSCLKOUT)

GpioCtrlRegs.GPAMUX1.bit.GPIO0 = 0; //GPIO0 = GPIO0

GpioCtrlRegs.GPADIR.bit.GPIO0 = 0; //GPIO0 = input

// SMBUS Alert functionality (GPIO2 = Alert line)

GpioCtrlRegs.GPAPUD.bit.GPIO2 = 0; //Enable pullup on GPIO2

GpioDataRegs.GPASET.bit.GPIO2 = 1; //Drive line high

GpioCtrlRegs.GPAMUX1.bit.GPIO2 = 0; //GPIO2 = GPIO2

GpioCtrlRegs.GPADIR.bit.GPIO2 = 1; //GPIO2 = output

slave_address = PMBusSlave_DeviceAddress;

I2CSlave_Init(slave_address); // Initialize USCI module

}I2CSlave_Init函数:

该函数配置内容如下:

1、I2C用到的GPIO即SDA和SCL;

2、timer0和timer1的配置及对应的ISR;

3、I2C的中断配置及对应的ISR;

TI示例中原来的方案是采用轮询的方式来运行PMBus协议,也就是在主循环中调用PMBusSlave函数,这里我使用的是中断方式,每次产生I2C中断时就调用StartCpuTimer0函数启动timer0,如果数据正确则调用StopCpuTimer0函数关闭timer0,否则执行超时机制,一般是重置I2C模块。

timer1用于1毫秒定时,产生LED灯闪烁,另外用于监测I2C从机的状态,特别是SDA信号被长时间拉低导致总线卡死,这时就需要重置I2C,监测的函数是PMBus_Error_Detect,在主循环中调用。实际调试我使用TOOMOSS的USB转I2C设备,故意使用错误的数据长度,不按PMBus规范发送数据,确实会产生这种错误,即使没有产生错误,或者通过I2C主机也可以解决I2C死锁问题,但是为了程序的健壮和可靠,也需要做一些预防措施确保总线的稳定。

图1显示了在TOOMOSS设备中的测试画面,以0x21指令为例,测试结果收到的数据和图2中的RWWORD命令组发送的数据一致:

图1:

在I2C的中断处理函数__interrupt void I2CISR(void)中,我增加了一个函数i2c_sent_timeout,用于发送超时处理,实际运行时发现在执行RWWORD指令时while(I2caRegs.I2CSTR.bit.BYTESENT != 0x1)有时出现死循环,因此增加了超时处理机制。测试中我使用的是自定义数据,当然用户可根据实际应用结合PMBus协议在函数PMBusSlave_DecodeCommand中设置PMBusSlave_TransmitBuffer数组成员值,如图2和图3所示:

/***************************************************************************//**

* @brief Initialize I2C module in slave mode.

* @param I2CSlave_OwnAddress The slave device's own address.

* @return None

******************************************************************************/

void I2CSlave_Init(Uint16 I2CSlave_OwnAddress)

{

GPIO_SetupPinMux(GPIO_PIN_SDAA, GPIO_MUX_CPU1, 3); //Technical reference manual of page 45 for the alternate function of GPIO35 and GPIO37

GPIO_SetupPinOptions(GPIO_PIN_SDAA, GPIO_OUTPUT, GPIO_PULLUP);

GPIO_SetupPinMux(GPIO_PIN_SCLA, GPIO_MUX_CPU1, 3);

GPIO_SetupPinOptions(GPIO_PIN_SCLA, GPIO_OUTPUT, GPIO_PULLUP);

//Setup CPU Timer 0 interrupt

EALLOW; // This is needed to write to EALLOW protected registers

PieVectTable.TIMER0_INT = &cpu_timer0_isr;

PieVectTable.TIMER1_INT = &cpu_timer1_isr;

EDIS; // This is needed to disable write to EALLOW protected registers

// Enable TINT0 in the PIE: Group 1 interrupt 7, 请参考技术手册第90页表格的第一行

PieCtrlRegs.PIEIER1.bit.INTx7 = 1;

//PieCtrlRegs.PIEIER1.bit.INTx13 = 1;

//Interrupt_enable(INT_TIMER1);

CpuTimer0Regs.TCR.all = 0x4000;

CpuTimer1Regs.TCR.all = 0x4000;

//

// Enable CPU int1 which is connected to CPU-Timer 0

// CPU int13: which is connected to CPU-Timer 1

// CPU int14: which is connected to CPU-Timer 2

//

IER |= M_INT1;

IER |= M_INT13; //Timer1 interrupt is enabled

//IER |= M_INT14;

InitCpuTimers();

ConfigCpuTimer(&CpuTimer0, 60, 35000); //CPU Timer 0 interrupt after 35 ms (at 60MHz CPU freq.)

ConfigCpuTimer(&CpuTimer1, 100, 1000); //CPU Timer 1 interrupt after 1 ms (at 100MHz CPU freq.)

//

// Register the interrupt ISR for I2C interface

//

EALLOW; // This is needed to write to EALLOW protected registers

PieVectTable.I2CA_INT = &I2CISR;

EDIS; // This is needed to disable write to EALLOW protected registers

//

// Enable Interrupts

//

PieCtrlRegs.PIEIER8.bit.INTx1 = 0x1; // Enable PIE Group 8 INT8,I2CA的中断允许位,请参考技术手册第90页表格中的INT8.y

IER |= M_INT8; // Enable CPU INT8

EINT;

// Enable Global Interrupts

ERTM;

EnableInterrupts();

EALLOW;

I2caRegs.I2CMDR.all &= ~(0x20U); // Reset the I2C Module

I2caRegs.I2CMDR.bit.MST = 0x0U; // Configure I2C as slave in Receive mode

I2caRegs.I2CMDR.bit.TRX = 0x0U;

I2caRegs.I2CMDR.bit.BC = 0x0U; // Set the bit count to 8 bits per data byte

I2caRegs.I2CMDR.bit.FREE = 0x1; // Set emulation mode to FREE

I2caRegs.I2COAR.all = I2CSlave_OwnAddress; // Configure I2C own address

I2caRegs.I2CSTR.all = 0xFFFF; //Clear all status

I2caRegs.I2CIER.all = 0x78; // Enable I2C Interrupts- AAS, STOP, XRDY and RRDY

I2caRegs.I2CMDR.all |= 0x0020; // Take I2C out of reset

EDIS;

//Initialize I2C

//I2caRegs.I2COAR.all = I2CSlave_OwnAddress; // Own address

//I2caRegs.I2CPSC.all = 9; // Prescaler - need 7-12 Mhz on module clk

//I2caRegs.I2CCLKL = 10; // NOTE: must be non zero

//I2caRegs.I2CCLKH = 5; // NOTE: must be non zero

//I2caRegs.I2CIER.all = 0x00; // Clear interrupts - polling based method

//I2caRegs.I2CMDR.all = 0x0020; // Take I2C out of reset

// Stop I2C when suspended

StartCpuTimer1();

return;

}图2:发送的示例数据

图3:在函数PMBusSlave_DecodeCommand中根据指令设置要发送的数据

这次的PMBus从机程序我没有使用PEC,这个只是数据包装和解析不同,其他的都是一样的,在此就不多说,完整工程可以从以下链接下载(不需要积分):

【免费】TMS320F280049CPMBus从机实现资源-CSDN文库

使用的软件版本信息如下:

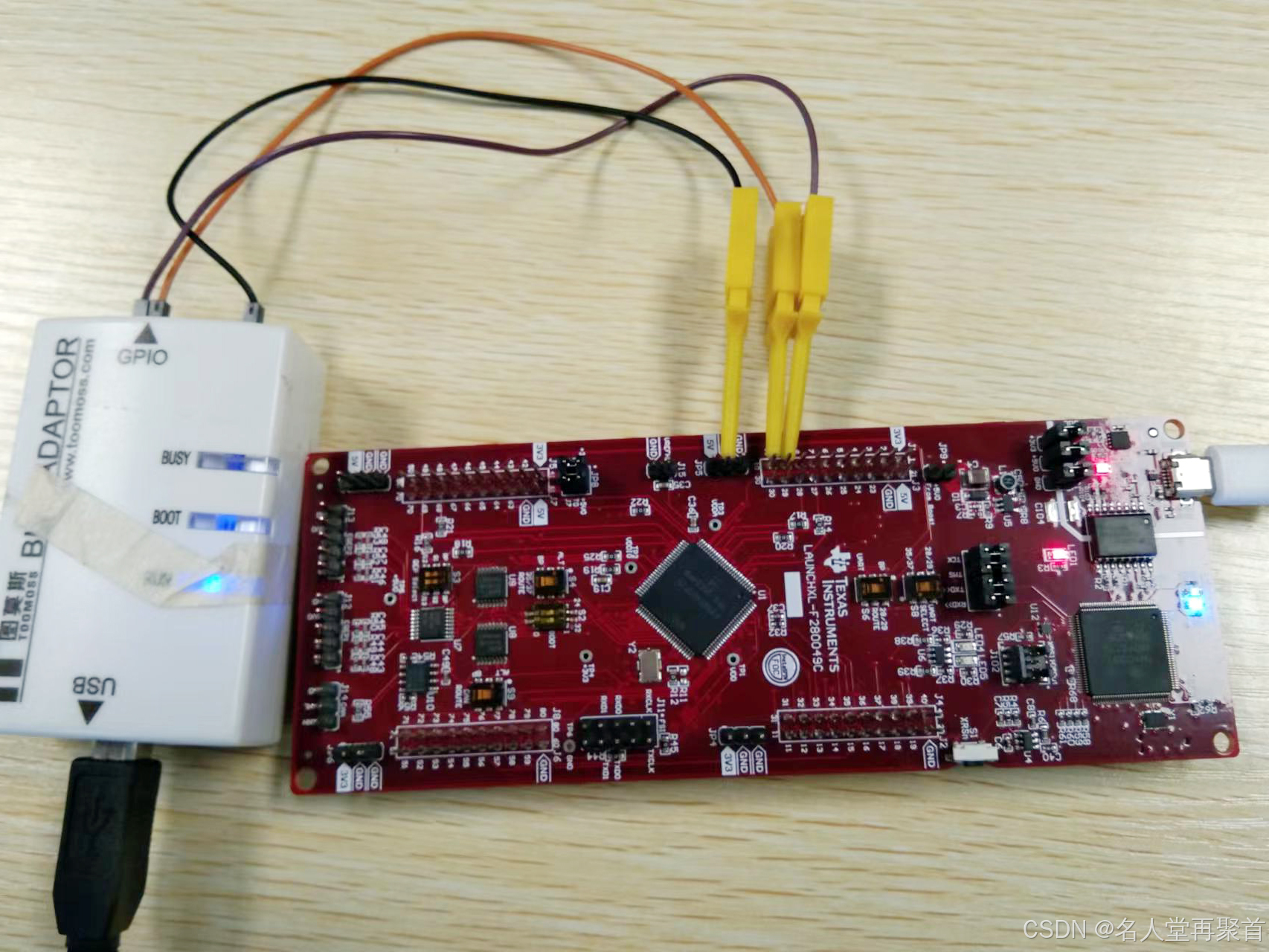

实验的硬件连接如下图所示:

1万+

1万+

被折叠的 条评论

为什么被折叠?

被折叠的 条评论

为什么被折叠?