CA10B解放牌汽车变速叉工艺规程和工艺装备的设计

学生姓名:

指导教师:

所在学院:

专 业:机械设计制造及其自动化

年 月

摘 要

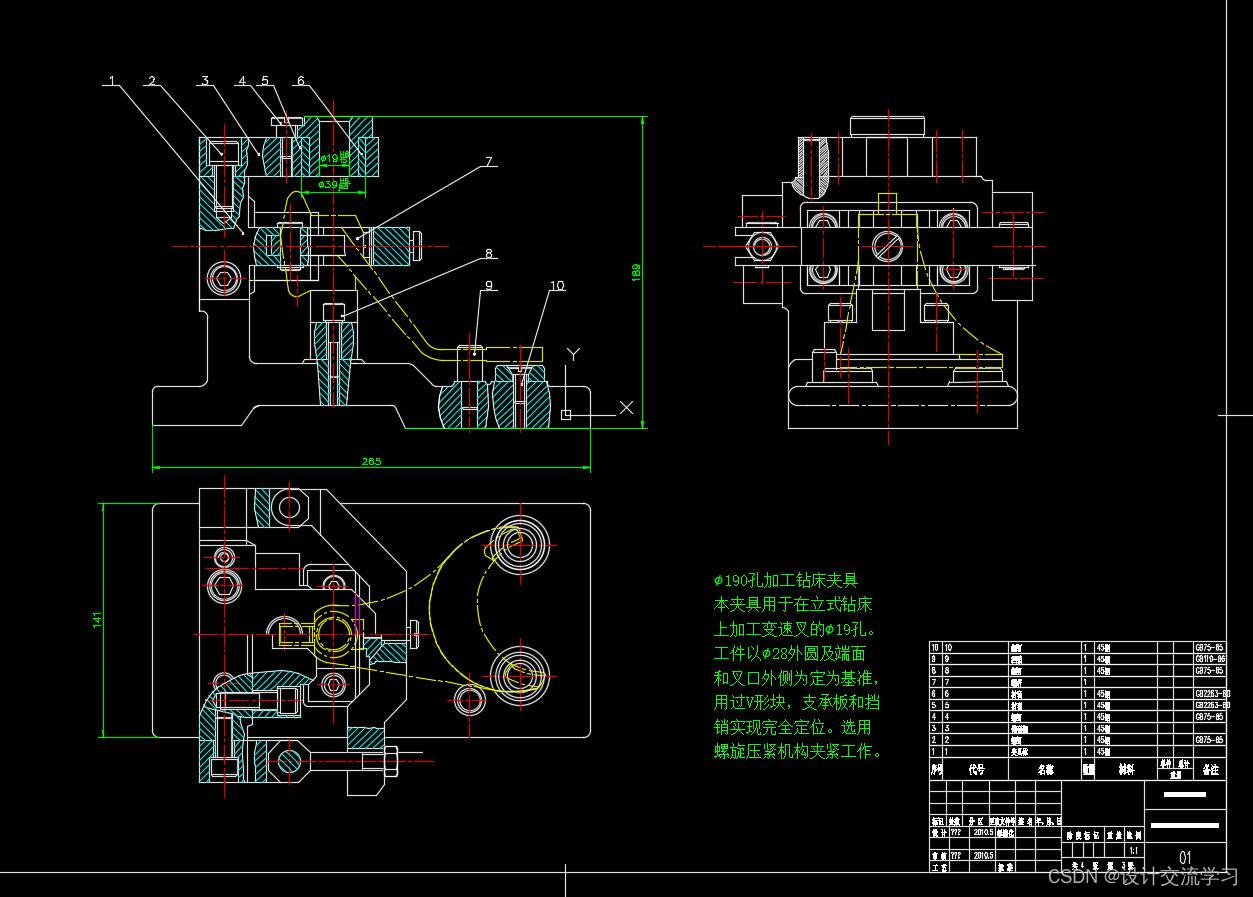

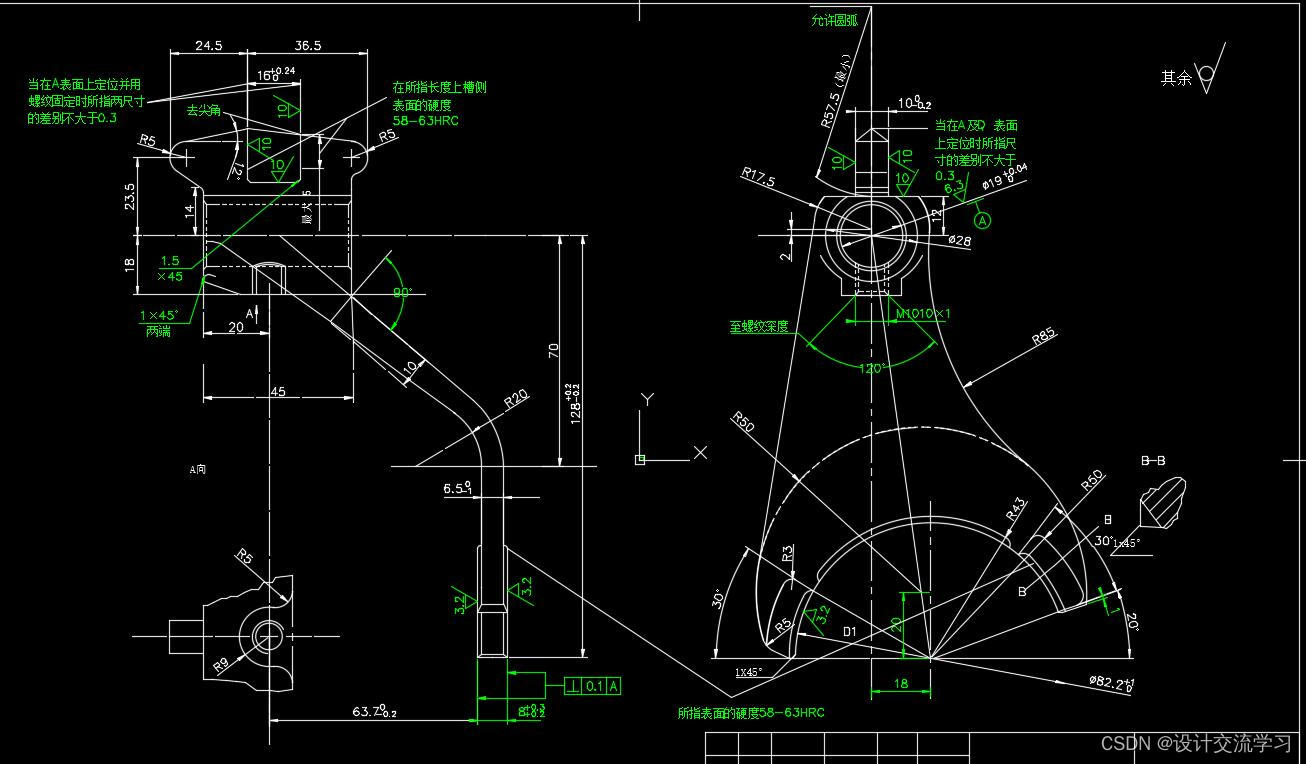

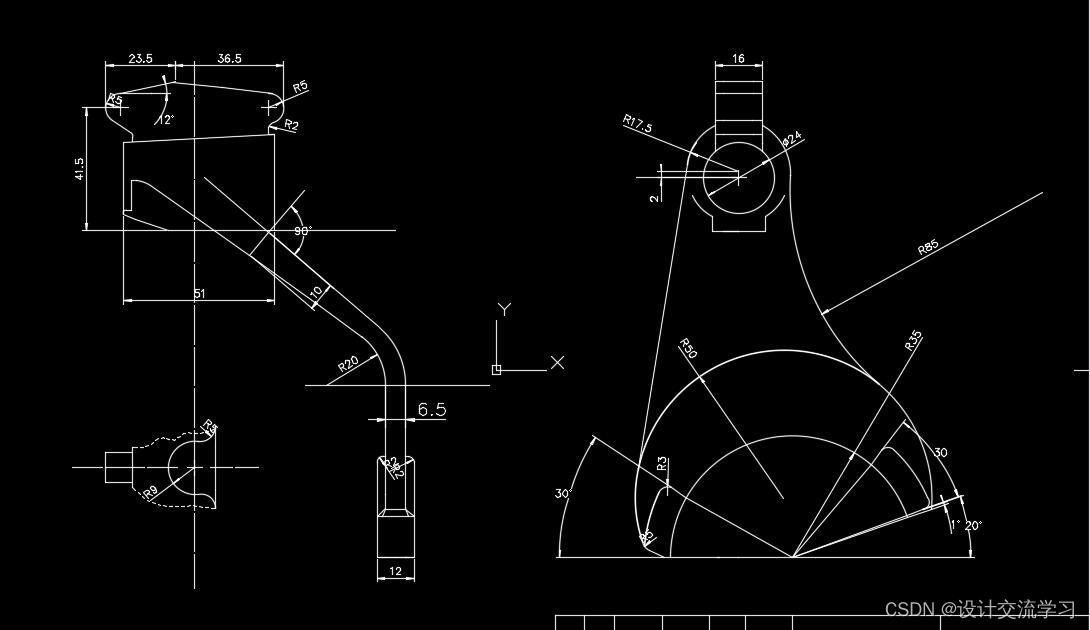

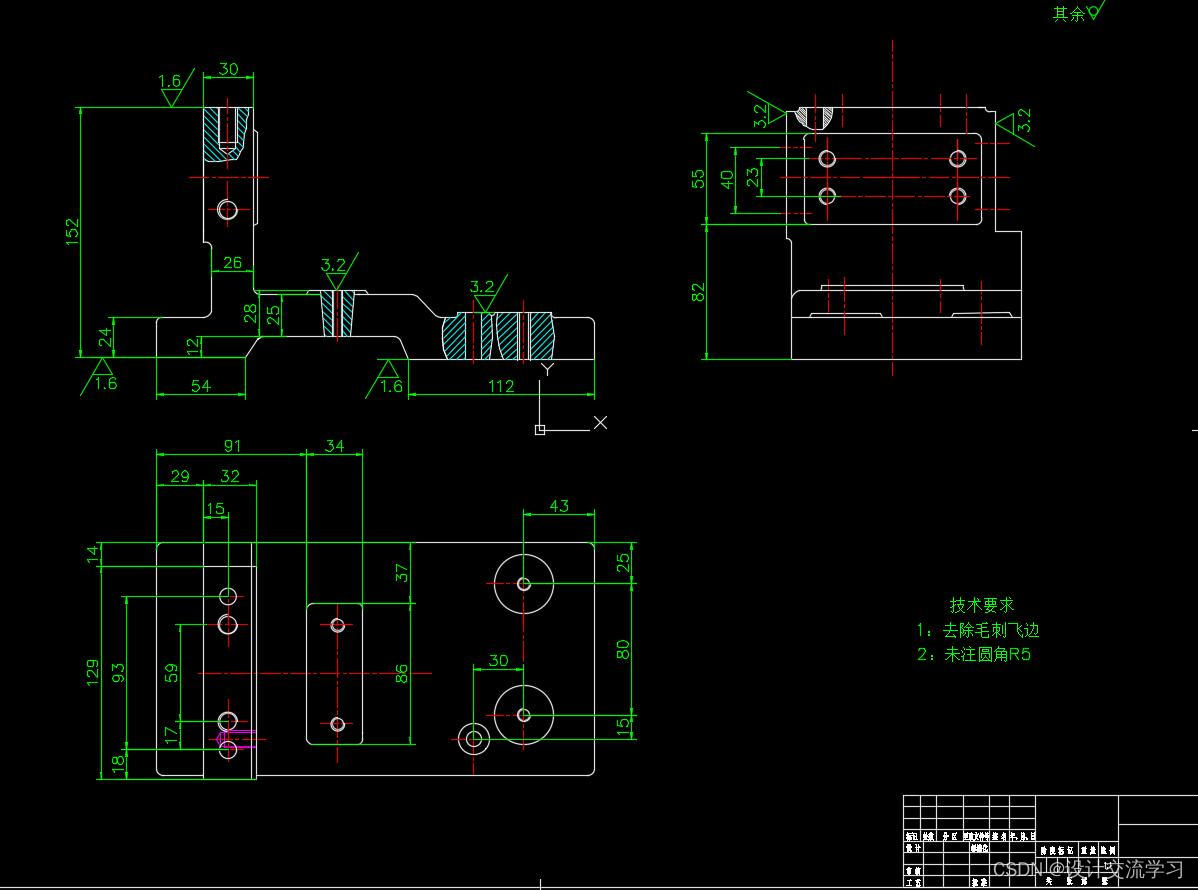

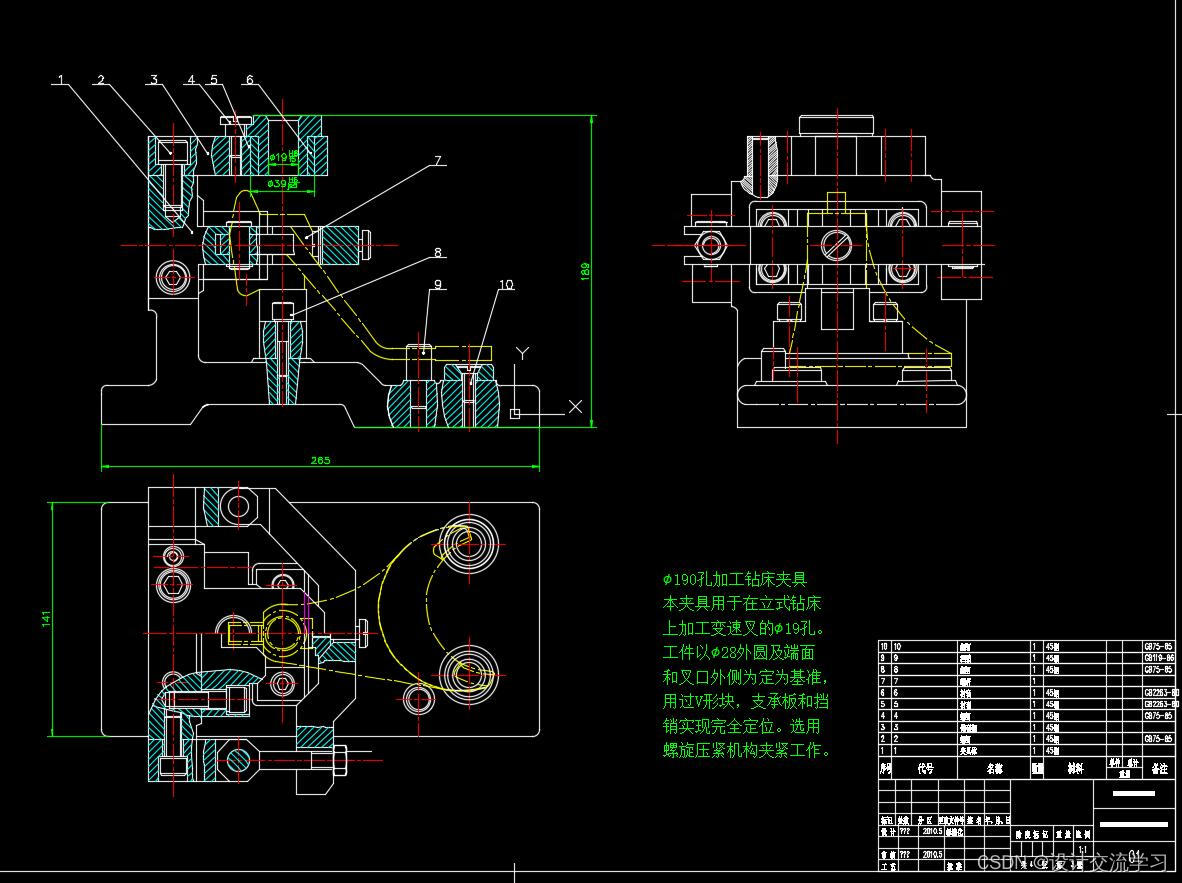

本次设计是汽车变速箱中变速叉零件的加工工艺规程及一些工序的专用夹具设计。此变速叉零件的结构较为复杂,其加工的地方主要是孔和平面。本设计先加工孔后加工面。将孔与平面的加工明确划分成粗加工和精加工阶段以保证它们的加工精度。基准选择以变速叉右面的最大的平面作为粗基准,来加工中间的通孔,然后以此加工过的孔作为精基准。主要加工工序安排是先以中心孔定位加工出顶平面和右侧平面以及下面的大孔的两平面,再以中心孔定位加工出下端的大孔。加工时是用镗床镗孔。最后以这两个孔为基准,分别加工右侧的槽和顶面的螺纹底孔。整个加工过程选用了钻床、铣床和镗床。工件在机床上定位夹紧选用专用夹具,夹紧方式为手动夹紧,夹紧可靠,操作方便。因此生产效率较高,适用于中批量、流水线上加工。能够满足设计要求。

关键词: 加工工艺 定位 夹紧 专用夹具

This design is a lather to become soon an appropriation for inside pulling out fork spare parts processing craft rules distance and some work prefaces tongs design.This pull out the construction of the fork spare parts than for complicacy, its the place that process is a peaceful in bore primarily.This design processes after processing first the bore.Process with flat surface the clear and definite dividing the line the bore the coarseness processes to process with the nicety the stage to guarantee their process the precise degree.The basis choice to pull out rough basis of conduct and actions of the biggest flat surface of the right in fork, process the in the center in general use bore, then be used as the precise basis with the bore that processed.Processing primarily work preface arrangement is first to process a flat surface with the center bore fixed position with the right side flat surface and below big bore of two flat surface, again with center bore the fixed position processes the big bore that carry down.While processing is to use the boring machine boring bore.Regard these two bores as the basis finally, process the right-hand slot respectively with the thread bottom bore of the a.Whole processes the process chose to use to the drill machine, miller with the boring machine .The tongs chooses to use the appropriation tongs, clipping tight way as to move to clip tight, clip tight and dependable, operation convenience.Therefore produce the efficiency higher, be applicable to the middle quantity measures, the flowing water is on-line to process.Can satisfy the design request.

Keywords Process the craft,Fixed position,Clip tight,Appropriation tongs

目录

……

该设计详细阐述了汽车变速箱变速叉的加工工艺流程,包括从粗加工到精加工的步骤,基准选择和工序安排。使用钻床、铣床和镗床进行加工,并设计了专用夹具以确保定位和夹紧的精度,适合中批量生产。整个工艺旨在满足精度要求并提高生产效率。

该设计详细阐述了汽车变速箱变速叉的加工工艺流程,包括从粗加工到精加工的步骤,基准选择和工序安排。使用钻床、铣床和镗床进行加工,并设计了专用夹具以确保定位和夹紧的精度,适合中批量生产。整个工艺旨在满足精度要求并提高生产效率。

623

623

被折叠的 条评论

为什么被折叠?

被折叠的 条评论

为什么被折叠?