摘 要

压缩机曲轴轴颈及曲轴销是动配合,要求表面粗糙度通常在Ra0.4以下,常用磨削的方法加工及抛光。由于其形状不规则,安装复杂,产量低,加工成本高,设备昂贵。提出采用振动抛光机专用设备进行抛光。

抛光是超精密加工中一种重要加工方法,其优点是加工精度高,加工材料范围广。抛光机是用嵌入磨料的研具对工件表面进行研磨的工具,是保证研磨加工的重要条件。由于传统研磨存在加工效率低、加工成本高、加工精度和加工质量不稳定等缺点,这使得传统研磨应用受到了一定限制,为了提高研磨加工效率,机械研磨机已经取代了传统的手工研磨。

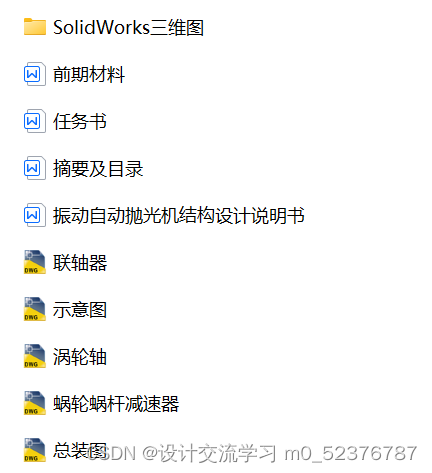

本文主要是合理的分析了振动抛光机的传动系统和抛光原理,本振动抛光机设计由电动机、减速装置、振动马达、振动盘等组成,并设计了减速装置。为了使其具有足够的刚度、强度和稳定性,对蜗轮蜗杆减速器上的主要零部件进行了寿命校。

关键词:曲轴;振动抛光;蜗轮蜗杆;

Abstract

Compressor crank journal and crank pin is moving with the surface roughness is usually in the following Ra0.4 commonly grinding machining and polishing. Because of its irregular shape, installation complexity, low-yield, high processing costs, expensive equipment. Proposed special equipment vibration polishing machine polishing.

Polishing is an ultra-precision machining processing method, the advantage of high precision machining and processing a wide range of materials. The polishing machine is embedded abrasive lap on the workpiece surface grinding tool, is an important condition to ensure that the abrasive machining. Traditional grinding low processing efficiency, processing costs, unstable machining precision and quality shortcomings, which makes traditional grinding application subject to certain restrictions, in order to improve the efficiency of grinding, mechanical polishing machine has replaced the traditional hand-grinding.

This paper is reasonable analysis of vibration polishing machines the drivetrain and polishing principle, the vibration polishing machine design by the motor, deceleration device, vibration motor, vibration disk, and the design of the deceleration device. In order to have a sufficient rigidity, strength and stability of the main parts of the worm gear reducer school life.

【Key word】Crankshaft; vibration polishing; worm

目 录

…………

763

763

被折叠的 条评论

为什么被折叠?

被折叠的 条评论

为什么被折叠?