摘 要

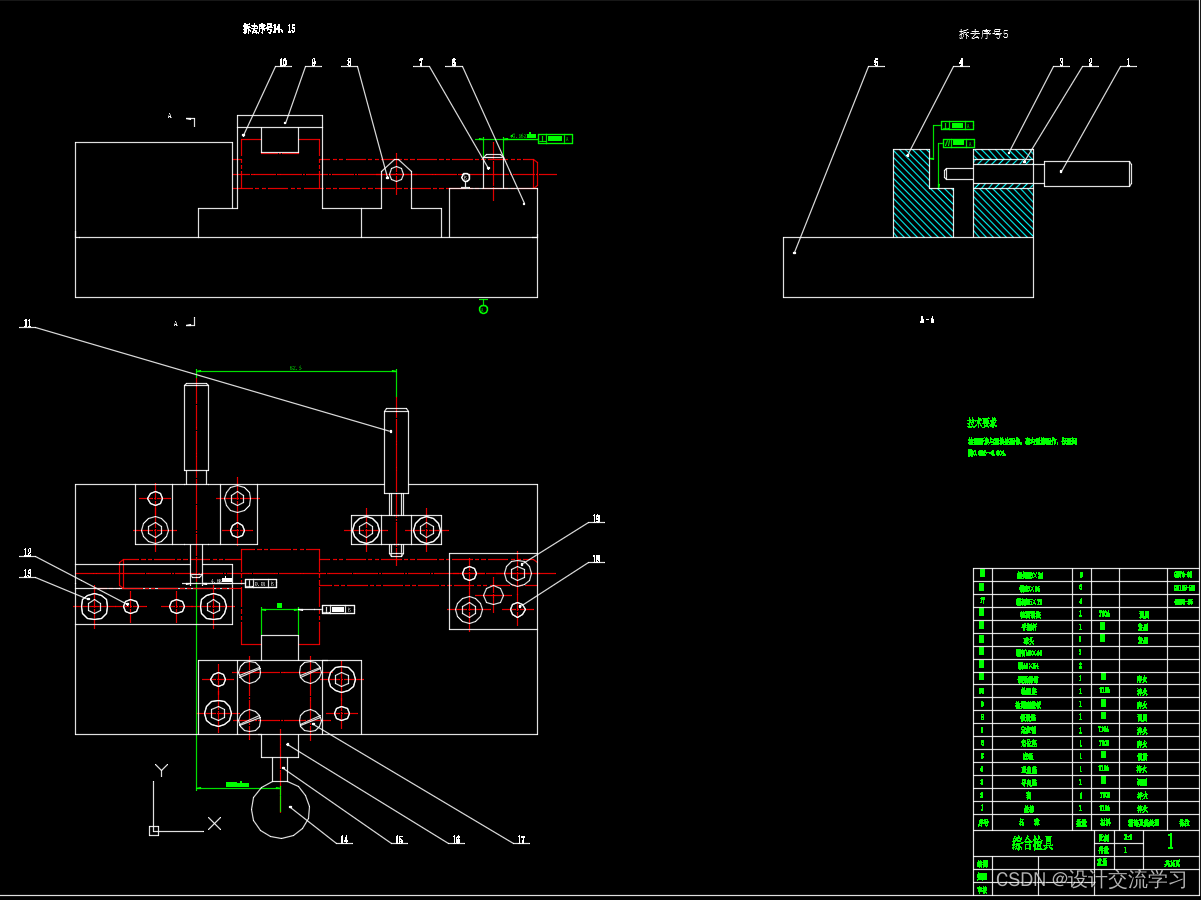

根据连接轴尺寸设计出SC63311-2综合检具,制订该综合检具总体设计。在分析产品零件图,对综合检具总体部件进行设计,并通过连接轴设计出综合检具安装定位的定位公差来,以保证完成连接轴的定位和检测。对SC6331-2综合检具的设计总要包括一下三部分,根据连接轴的零件图与工艺简要分析,设计综合检具的部件,根据设计要求对综合检具的部件进行选材。设计说明书主要内容:设计说明书主要由以下几部分组成。首先对连接轴的工艺性作适当分析,然后对综合检具的部件尺寸进行设计。其次对综合检具的部件选材及做出加工要求作详尽的分析说明,明确设计思路。再次,具体说明所设计综合检具的工作原理,并综合定位误差、夹紧力等方面的分析计算来进一步论证利用此综合检具是否能达到检测要求。

关键词:综合检具 连接轴 定位 精饰及热处理

ABSTRACT

In designing the coupling shaft of the size of flights if sc63311 comprehensive.,the preparation of the comprehensive if the processing procedure using. We has drawn up the processing technical process of this crankcase , To be comprehensive if the overall component design, and by coupling shaft to design a comprehensive if the installation location of tolerance in order to ensure the completion of the parts of the location and testing. Sc6331 flights to be comprehensive if it is designed to include three parts, in accordance with parts of the process or a brief analysis, designing the parts, if based on the design calls for comprehensive if component timber assortment. Design specifications contained: Design specifications of the following parts. Firstly , the products to the process of analysis and synthesis of the components of the size of a design. Secondly , be comprehensive if the parts and make the processing requirement timber assortment a detailed analysis and design. Thirdly, the concrete expression of the comprehensive if the working principles and general orientation, the force for further analysis of the arguments of this comprehensive if it can to detect.

Key words: function go gage , coupling shaft , allocation , a decorative and heat treatment

目 录

中文摘要...........................................................I

英文摘要......................................................... .II第一章 绪论.........................................................1

1.1 选题背景....................................................1

1.2 综合检具概述................................................1

1.3 研究该题目的意义............................................2

1.4 综合检具国内外现状和发展趋势................................3

1.5 综合检具工作原理............................................6

第二章 综合检具总体设计.............................................7

2.1 综合检具设计要求............................................7

2.2 综合检具零件设计原则........................................8

2.3 定位装置设计................................................9

2.3.1 定位座与定位销..........................................9

2.3.2 直角座.................................................11

2.3.3 导向座、套和量棒.......................................12

2.4 夹紧装置设计...............................................14

2.5 检测装置设计...............................................16

2.6 底板设计...................................................18

第三章 零件加工工艺流程及工艺分析..................................21

3.1 工艺流程分析...............................................21

3.2对连接轴制定出的加工顺序...................................21

总结...............................................................23

参考文献...........................................................24

致谢...............................................................26

…………

文章详细介绍了SC63311-2连接轴的综合检具设计过程,包括部件设计、选材、定位和检测装置的构建。通过对连接轴的工艺性分析,设计了满足检测要求的检具,并探讨了其工作原理。此外,还涵盖了工艺流程和加工顺序的制定。

文章详细介绍了SC63311-2连接轴的综合检具设计过程,包括部件设计、选材、定位和检测装置的构建。通过对连接轴的工艺性分析,设计了满足检测要求的检具,并探讨了其工作原理。此外,还涵盖了工艺流程和加工顺序的制定。

634

634

被折叠的 条评论

为什么被折叠?

被折叠的 条评论

为什么被折叠?