摘 要

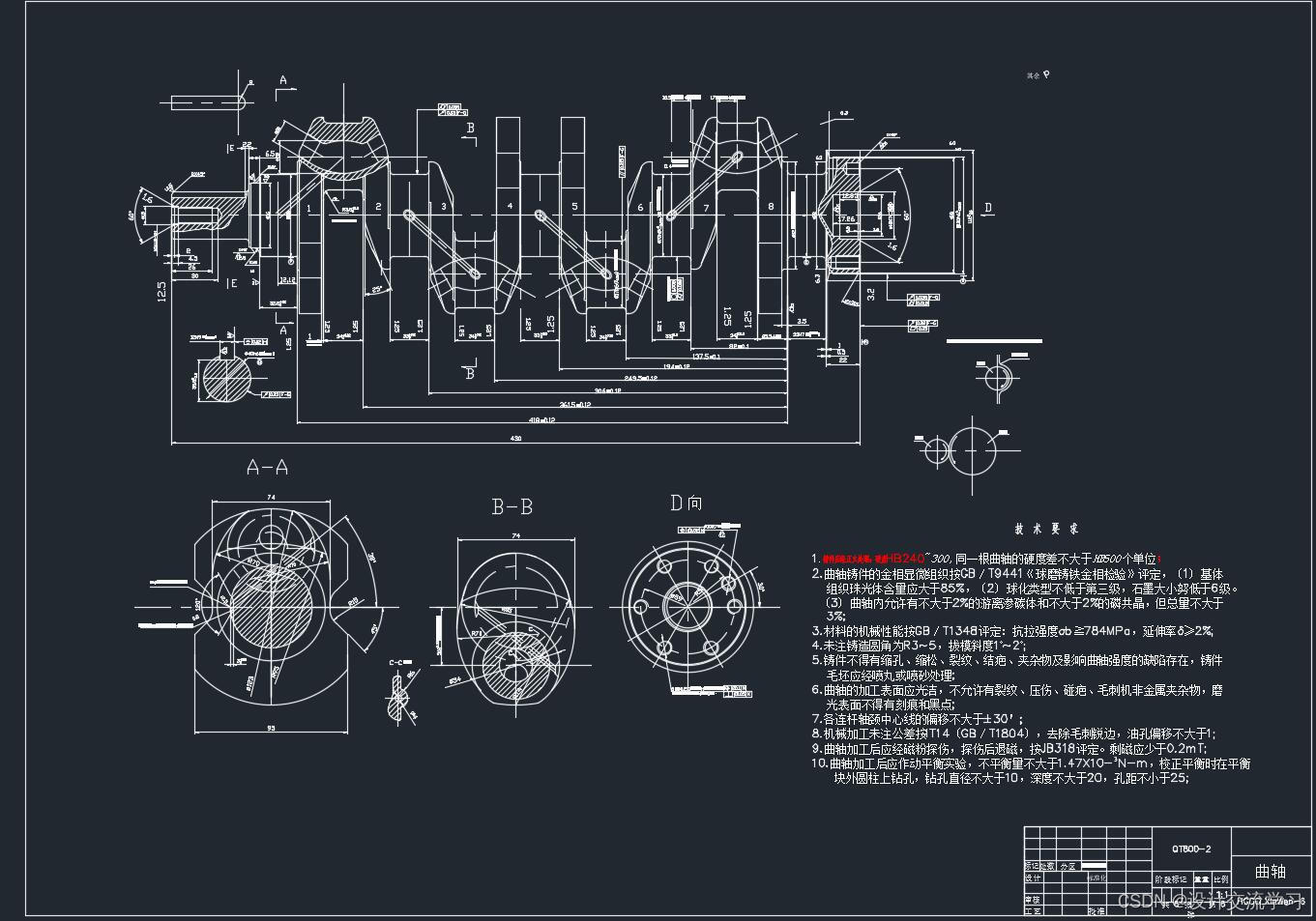

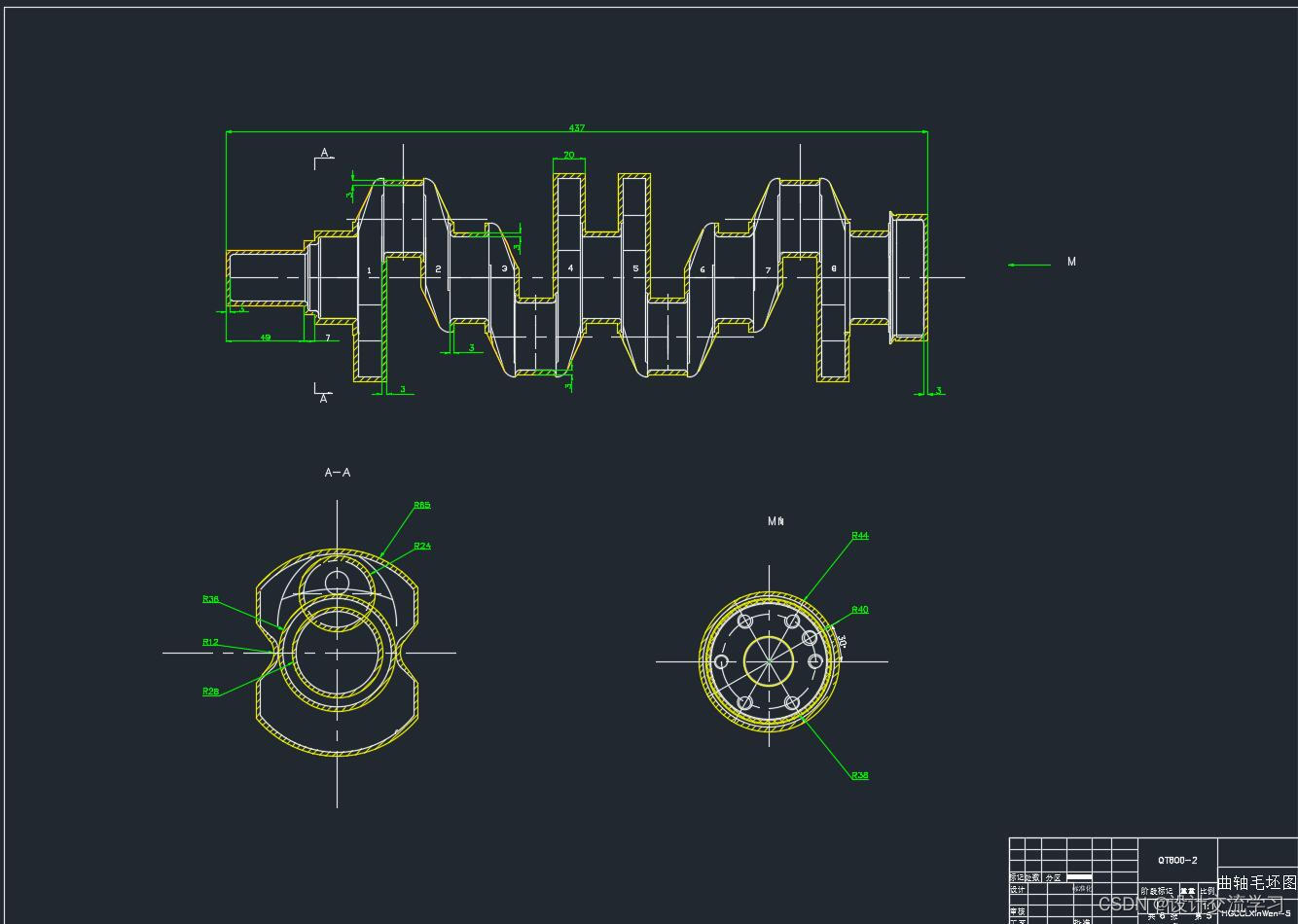

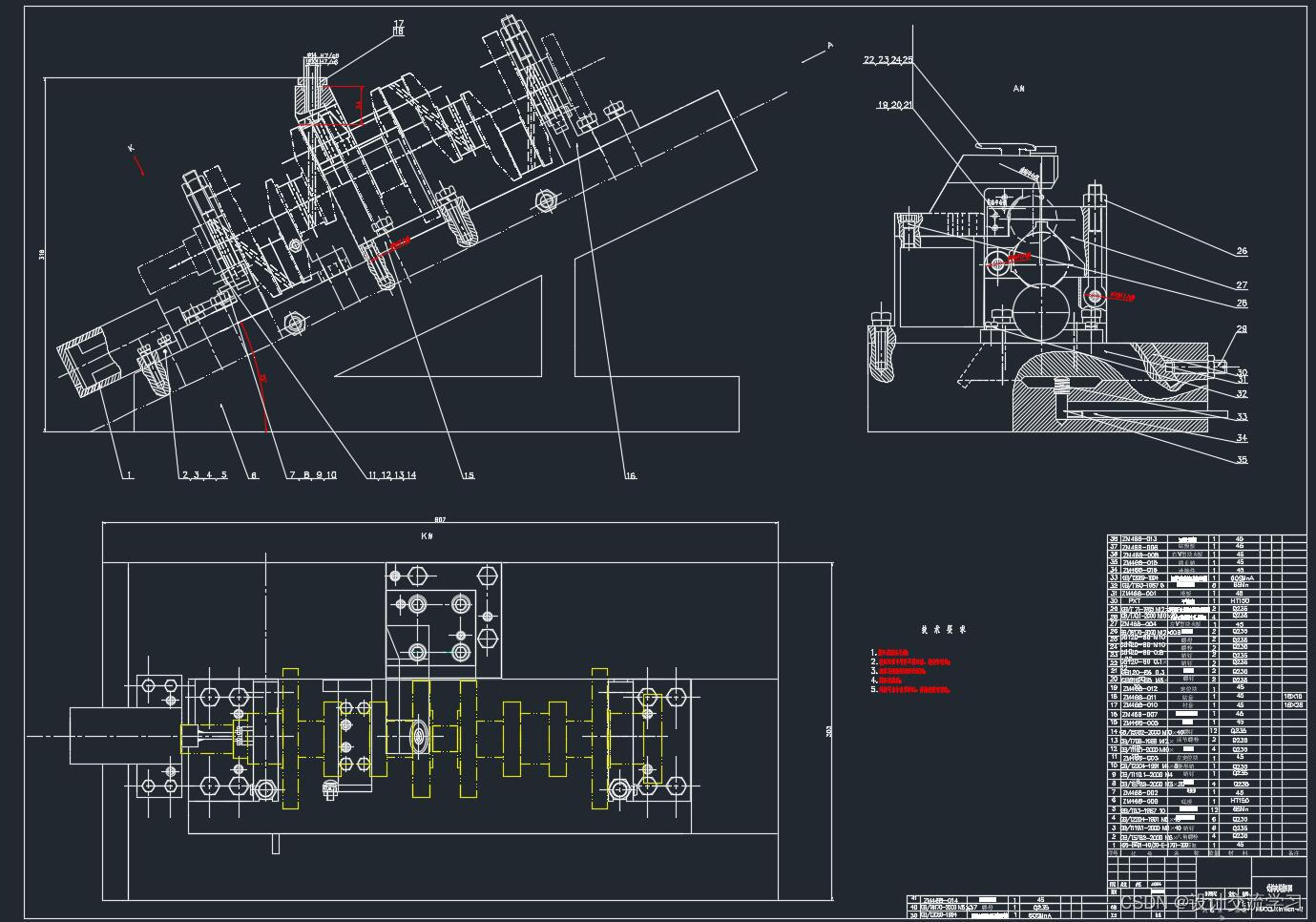

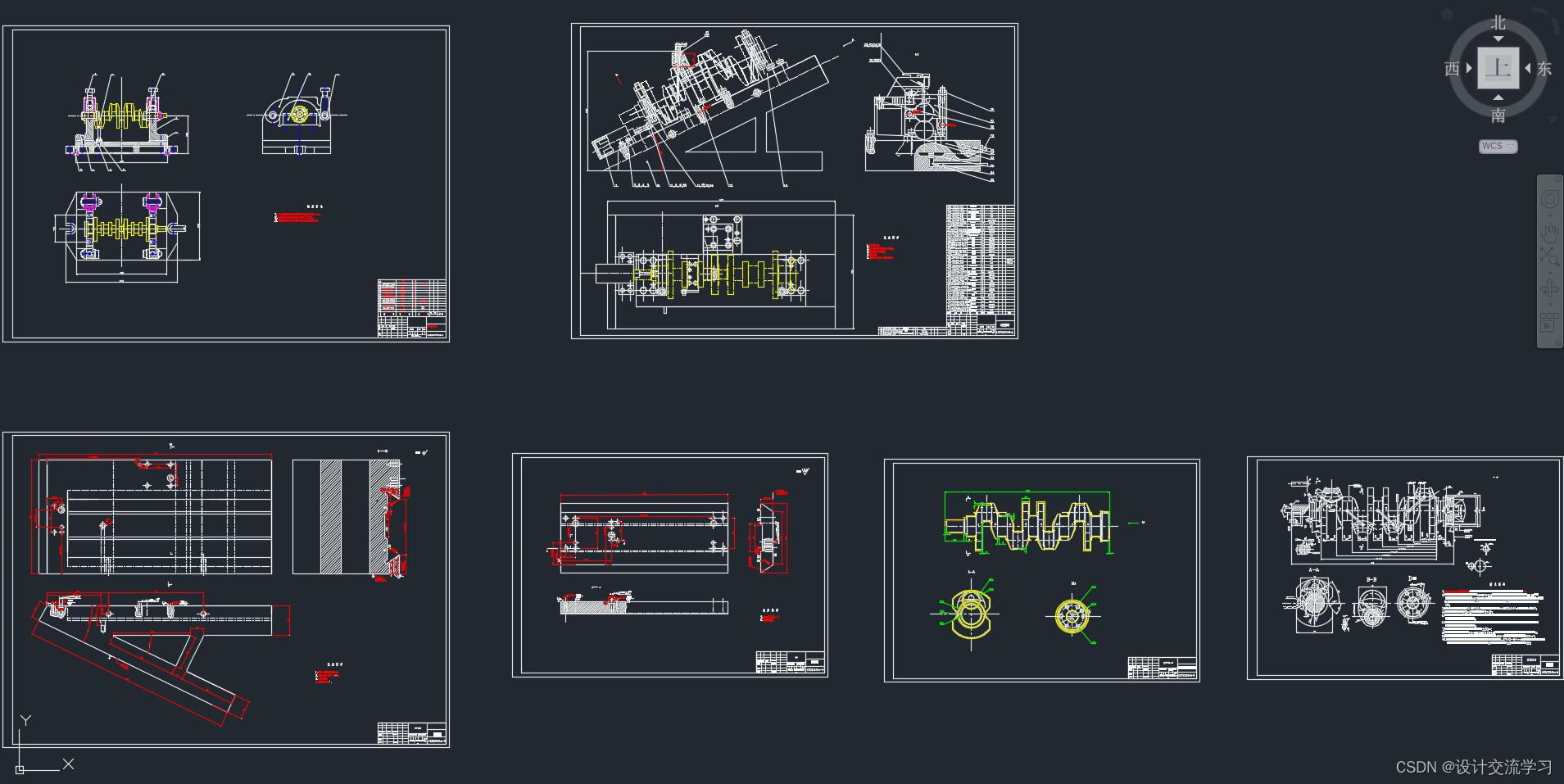

本设计主要围绕发动机曲轴的工艺规程和专用夹具设计进行研究,其内容包括了解曲轴结构,确定曲轴的生产类型及相关的技术要求。在此基础上,选择毛坯,确定毛坯的尺寸公差和机械加工余量,绘制毛坯图。并在认真详细分析零件图后,进行基准的选择,制定了表面加工方法,划分加工阶段,根据生产类型确定工序的集中和分散,合理地安排工序,编排合适的工艺路线;进行详细计算,包括:加工余量、工序尺寸和公差的确定、切削用量的计算及时间定额的计算。从而制定出一套合理的机械加工工艺卡片和机械加工工序卡片。

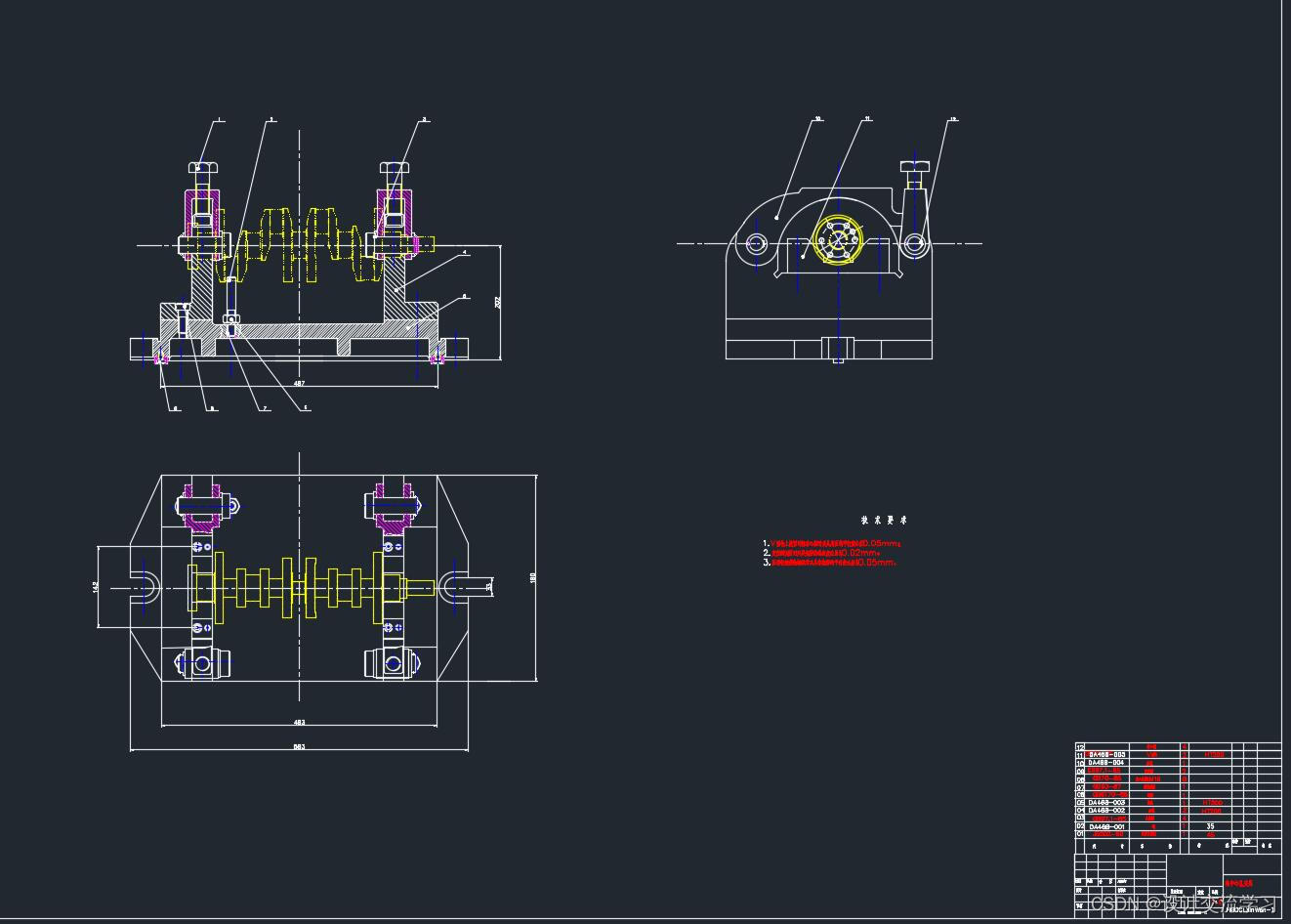

第二部分主要围绕专用钻床类夹具进行设计。首先明确夹具设计的主要任务,通过确定定位元件,导向装置,夹紧机构得出夹具的结构方案,查阅相关国家标准,绘画夹具装配图。

总之,曲轴加工工艺的安排以及专用夹具的设计是一项非常复杂的高难度工作,它是一种需大批量生产的零件,且技术要求比较高,为了确保产品的质量和水平,设计工作按照科学的程序进行,分清主次。

关键词:曲轴;加工工艺;定位;夹紧;钻孔;夹具设计

ABSTRACT

In this paper the technological procedure and proprietary drilling fixture design of the engine crankshaft were studied, whose contents included that the use of crankshaft, the production type of crankshaft of and the relevant technical requirements. On this basis, the rough was chosen, and the size of the rough was determined, and the mechanical allowances were determined. A rough map was drawn. After carefully detailed analysis of the parts, the reference was chosen, the development of surface processing methods was determined, and the demarcation of the processing stages was divided. According to the production process the type of centralization and decentralization was determined, the process was reasonably arranged, and the order and orchestrates a suitable process line were set up. Then some detail was calculated, such as allowance, processes size and the determination of tolerance. The amount of calculation and the calculation of the fixed time was cut. Thus a set of reasonable card processing machinery and mechanical processes cards were drawn up.

The second part of the design was the focus of this issue which was difficult, who was mainly centered on proprietary drilling fixture design, Z525-use vertical drilling, drilling middle-hole design process by which a drilling fixture. Firstly fixture was designed to clear the major tasks identified by positioning components, guidance devices, clamping body fixture structure, access to the relevant national standards, painting fixture assembly.

In short, the processing arrangements of crankshaft and the design of special fixture are a very complex difficult work. It is required in mass production. The technical requirements are relatively high. In order to ensure the quality and level of design the design work was carried out in accordance with the procedures of science, the relation between primary and secondary was distinguished.

Keywords: Bent axle; Processing technical; Cutting parameters; FixtureDesign

结论 40

致谢 42

附录 43

…………

该设计涉及发动机曲轴的工艺规程制定和专用夹具设计。内容涵盖曲轴结构理解、生产类型和技术要求分析、毛坯选择与尺寸公差设定、工艺路线规划和夹具设计,包括定位元件、导向装置和夹紧机构的选择。设计目的是确保大批量生产的曲轴质量和精度。

该设计涉及发动机曲轴的工艺规程制定和专用夹具设计。内容涵盖曲轴结构理解、生产类型和技术要求分析、毛坯选择与尺寸公差设定、工艺路线规划和夹具设计,包括定位元件、导向装置和夹紧机构的选择。设计目的是确保大批量生产的曲轴质量和精度。

352

352

被折叠的 条评论

为什么被折叠?

被折叠的 条评论

为什么被折叠?