This article continues the discussion of my previous 2 articles ’Extend the CPS concept, remodel the company organization ’ and ‘ Self-aware value network in the context of i4.0’.

With the development of an enterprise, the numbers of application software increases, and this for sure will create silos and barriers. So shall this situation to be continued in the era of i 4.0? What if we change mind, we don’t implement for enterprises with applications with system boundaries?

Quote from one the most famous writer in China: There’s no road in the world, as people keeping walking on it, there’s a road.

Similarly, there’s no systems in the physical world of an enterprise or the physical world, neither any boundaries.

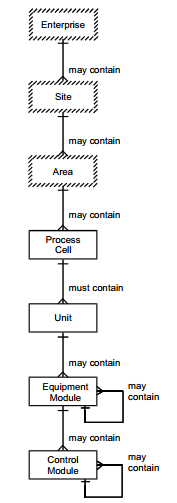

The following picture from ISA88 standards shows a enterprise physical structure:

And accordingly, in ISA95 there’s level structure for software applications:

The interfaces between each level, especially between level 3 and level4, between level 3 and level 2, are the root cause of silos. And that’s why i4.0 mentioned about the keyword vertical integration.

What I’m suggesting is, to eliminate the level structure.

If you’ve experience with the control software of equipment or automation control, you shall know, the control PC of an equipment master all the information about the equipment, it can display in real-time the information about each chamber, transferring unit, sensors and even each pumps, and some of them may support 3D view; it has full control rights to all the actionable units, it provides recipe edit and other execution functions, some even can have some routing and scheduling function over works.

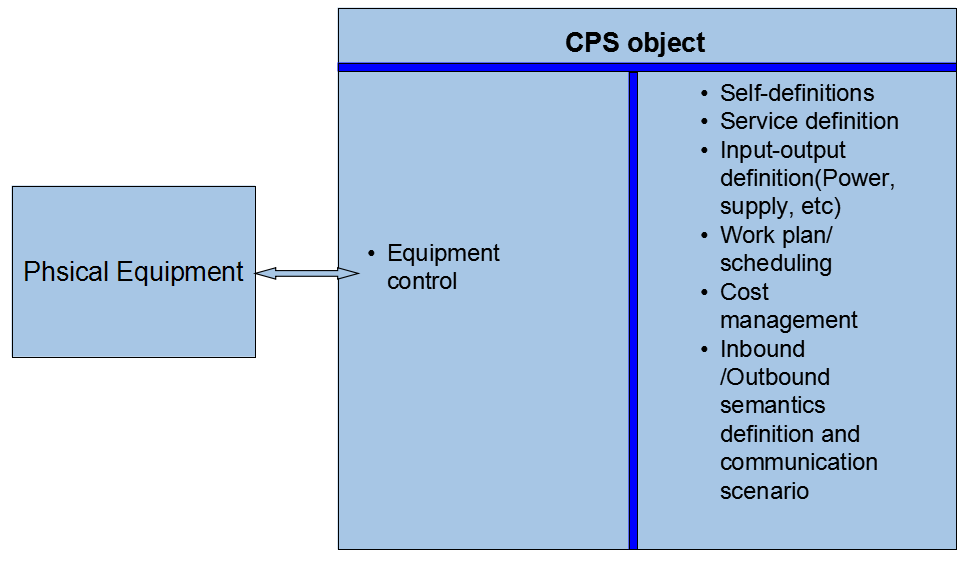

Extend the control software, other than existing functions, it shall also have the CPS functions as described(You can check my previous blog article ‘Extend the CPS concept, remodel the company organization’), to maintain the basic self-definitions, input/output, service definition, cost management, work plan and scheduling, the communication semantics and the scenarios to outside.

As following picture:

As my concept described in the ‘Extend the CPS concept, remodel the company organization , the enterprise’s gonna be formed by many different CPS objects, each of them have full control over the physical assets and provide some service to others. There’s no levels, only the combination of CPS objects and the connection of their services. Thus accordingly, the software application can be in following loose and open way:

2 examples to explain the usages:

1)Cost management

CPS objects define and monitor all the input/output materials and the power supply。

The consumption of power supply can be calculated in real-time, the consumption during idle time and meanwhile the equipment depreciation won’t be allocated to WIPs.

Before processing(Including material handling/logistics), the cost information of input material/WIP shall be provided by upstream CPS object(can be upstream equipment, material handling system or a facility pipe), after processing, this CPS object adds up the supply and depreciation to the WIP cost and pass it over to downstream.(You can refer to my blog article ‘A new way of real-time product costing’)

2) Work plan and scheduling

You can look into my blog article ’Self-aware value network in the context of i4.0 ’, I described 4 steps scenario. Supply chain is pull mode. Similarly, the interaction between the CPS objects is pull mode. 1) Fore-ward CPS objects receives the request from back-ward ones; 2) calculate, pass it backward, assess respond from back-ward then respond to initial request; 3) Select the final decided path. 4) Execution step by step.

Each CPS objects maintain its own capacity plan, we can refer to ISA95 here, you might be familiar with the following picture, but as in here, this information are maintained by CPS object, not an upper system.

I will explain using a classical logistic example.

One of the most mentioned example of the total cost approach for logistic system is: A factory might need 2 service from a same logistic vendor in one single day. For say, ship some raw material to the factory in the morning and deliver the final goods to customer in the afternoon. If you don’t take the total cost approach, the logistic vendor might need deploy double capacity. That is, one loaded truck ship the raw material and left in the morning, another empty truck come in the afternoon and wait to ship out the final goods.

If we take my CPS object concept, the logistic company is a CPS object, while receiving the request from the factory, it publishes the information inside, question all the truck CPS object, each truck CPS object, according to its own schedule and status, calculates the feasibility(current location, time on road) and the cost info, provide feedback to logistic company’s CPS object.

Assume that the logistic company CPS object release the raw material delivery request first.

The respond from each truck might be as following:

|

| Truck 1 | Truck 2 | Truck 3 | Truck 4 |

| Shipping request 1, time,location, | ETA, cost if I do it | ETA, cost if I do it | ETA, cost if I do it | ETA, cost if I do it |

Then the logistic company CPS object can publish the final goods shipping request.

| Truck 1 | Truck 2 | Truck 3 | Truck 4 | |

| Shipping request 1, time,location, | ETA, cost if I do it | ETA, cost if I do it | ETA, cost if I do it | ETA, cost if I do it |

| Shipping request 2, time,location, | ETA, cost if I do it | ETA, cost if I do it | ETA, cost if I do it | ETA, cost if I do it |

Of course the respond from each truck CPS object is based on the selection the company CPS made for previous requests.

I delete the ones not been selected in each step for different request sequences to show the result.

|

| Truck 1 | Truck 2 | Truck 3 | Truck 4 |

| Shipping request 1, time,location, |

| ETA, cost if I do it |

|

|

| Shipping request 2, time,location, |

|

|

| ETA, cost if I do it |

|

| Truck 1 | Truck 2 | Truck 3 | Truck 4 |

| Shipping request 2, time,location, |

|

| ETA, cost if I do it |

|

| Shipping request 1, time,location, |

|

| ETA, cost if I do it |

|

The logistics company CPS need to select the best one. Because the best selection for each step won’t leads to the best select for the big picture. So, the logistic company CPS needs to publish N! different combinations of requests. After receiving the respond from each truck CPS for each step, sum up and select best one.

This can apply to process equipment, and the physical combinations of equipment and automation/logistic.

本文是之前的两篇文章:“扩展CPS概念,对企业信息系统进行重新建模”和“ 工业4.0背景下,具有感知能力的价值网络”的延续。

企业发展过程中,会不断地增加应用系统,久而久之之必然产生应用竖井和壁垒。那么工业4.0的时代,会否要出现类似的状况呢?如果换一个思路,我们从一开始就不尝试去给企业部署有系统边界的应用,那么结果会是如何?

套用鲁迅的话,世界上本没有路,走的人多了,也便成了路。

同样地,企业或物理世界中,本来就没有系统,也无所谓边界。

下图是ISA88标准里列出的一个企业物理架构的图。

ISA95里面对应用系统进行了分层:

每一层之间的接口,特别是第三层和第四层之间、第二和第三层之间,都是应用竖井产生的根源,也是工业4.0提出的关键字垂直化整合的根源。

我要提出的是,直接打通第二层到第四层。

如果你有接触过设备或自动化控制软件的话,你应该了解,设备控制电脑掌握设备所有信息,可以实时地显示各个腔体、传输机构、传感器、泵等等信息,有些可能会支持3D模式的显示;同时针对所有的可动作的元件有完全控制,提供配方编辑或其他命令执行功能;有些设备控制软件还可以对工作进行一定的排序。

在当前的这种设备控制软件基础上进行扩展,扩展后的功能包含两部分功能,一部分便是传统设备控制电脑所能提供的所有功能;另一部分则是这个设备的CPS对象功能(你可以回顾看一下我在“扩展CPS概念,对企业信息系统进行重新建模”里对设备CPS对象的描述。

),维护包括设备的基本定义、输入输出、服务能力和自身工作计划、成本管理、与外部CPS对象沟通的语义定义和通讯机制(它可以运行在云端,只需要保证和实体设备的通讯链接即可)。

如下图:

按照我在“扩展CPS概念,对企业信息系统进行重新建模”里的构想,企业会由多个CPS对象构成,每个对象对自身的实体拥有完全的掌控,都可以提供一些服务。再没有所谓的层级,而只是CPS对象及其服务的组合。那么相应的,企业的软件架构则可以是如下松散开放的结构:

举两个例子来阐述实际应用。

1)成本的计算

CPS对象针对本对象的实体定义并监控所有的输入输出的物料,能源。

实际消耗的能源可以实时统计,设备空闲状态时的能耗和设备折旧可以不归集给具体的产品。在加工处理(包括搬送)WIP时本对象收到的各种物料由输入方的CPS对象(可以是上游加工设备,可以是搬送物流系统,甚至可以是气体管路)提供成本信息,在加上本对象加工处理时消耗的能源和本对象折旧后,汇总成本信息到输出。(你可以参考一下我的博客里的“A new way of real-time costing”一文)

2)工作计划和调度

你可以回顾一下我在另一篇文章“工业4.0背景下,具有感知能力的价值网络”里描述的四段机制,价值链是拉式的。同样的,企业内的各个CPS对象的交互也是拉式的。1)前端的CPS对象收到后端的CPS对象的请求 2)逐级发出响应预案并向前传导评估最优方案并向后传导,3) 最前节点选定最终路径再逐级向后传导 4)从最后节点开始逐级完成实际工作或响应。

每个CPS对象维护自身的服务能力计划,这个我们可以再参考一下ISA95,你可能对下图也不陌生。不过这次,这个信息由CPS对象来维护。

下面就以一个经典的物流案例来阐述。

Total cost approach的一个经典问题是:一个工厂同一天可能会需要来自同一个物流供应商两项服务,比如上午运送原料到本厂,下午运出成品到客户。如果不采用Total cost approach的话,物理供应商可能需要调度双倍的运力。

如果以CPS对象的架构来看,物流企业本身是一个CPS对象,它在会收到工厂的送原料和运输成品的需求后,在对象内部发送信息,询问所有的货车CPS对象,每个货车CPS对象根据自身的能力计划,计算可行性(自身的位置,路途上可能花的时间)与相应成本,然后进行响应。

假设物流企业CPS对象先发布的是送原料的信息,那么各货车可以进行响应,

|

| Truck 1 | Truck 2 | Truck3 | Truck4 |

| Shipping request 1, time,location, | ETA, cost if I do it | ETA, cost if I do it | ETA, cost if I do it | ETA, cost if I do it |

接着物流企业CPS对象再次对内发出运输成品的请求,

|

| Truck 1 | Truck 2 | Truck3 | Truck4 |

| Shipping request 1, time,location, | ETA, cost if I do it | ETA, cost if I do it | ETA, cost if I do it | ETA, cost if I do it |

| Shipping request 2, time,location, | ETA, cost if I do it | ETA, cost if I do it | ETA, cost if I do it | ETA, cost if I do it |

当然,每个货车在针对后一个需求的响应是在决定了前一个响应的基础之上做出的。

所以如下,删掉每一个需求中未被选中的格子来标示:

|

| Truck 1 | Truck 2 | Truck3 | Truck4 |

| Shipping request 1, time,location, |

| ETA, cost if I do it |

|

|

| Shipping request 2, time,location, |

|

|

| ETA, cost if I do it |

|

| Truck 1 | Truck 2 | Truck3 | Truck4 |

| Shipping request 2, time,location, |

|

| ETA, cost if I do it |

|

| Shipping request 1, time,location, |

|

| ETA, cost if I do it |

物流企业 CPS 对象面临的则是如何选择最优,由于每一步的最优并不能保证全局的最优,所以,物流企业的选择是, N 个需求则会有 N! 个不同的需求发布顺序,每个货车 CPS 对象都据此顺序做出响应。物流企业 CPS 在收到所有需求的响应后,对每一个需求选出最优解,并计算总成本。

你可以想象一下,以上对工作计划和调度的讨论可以同样地套用在具体的生产工艺设备或者工厂内产线上的物流自动化上。

1万+

1万+

被折叠的 条评论

为什么被折叠?

被折叠的 条评论

为什么被折叠?