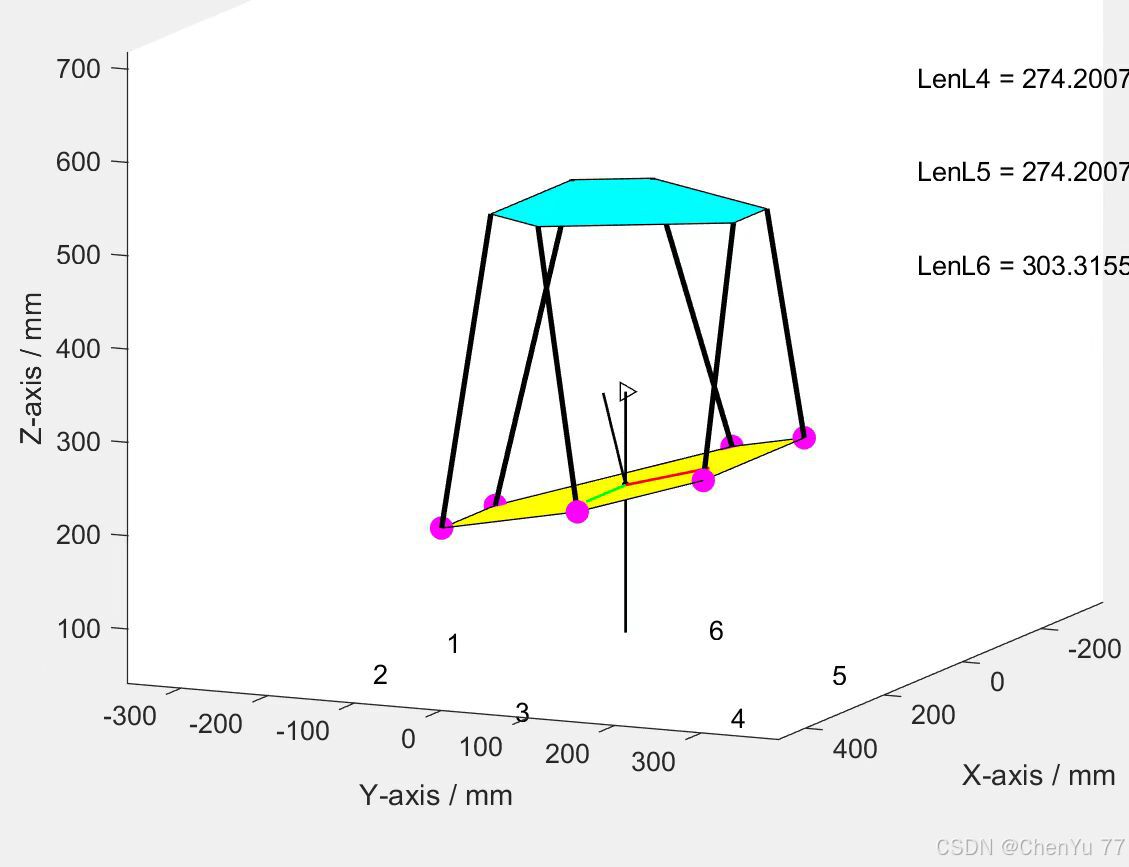

逆解算法(IK):逆解算法则是指根据给定的位姿,计算出机器人关节长度。逆解问题的求解过程用数值法求解相对比较简单,使用的公式也只有一个

相比较传统的inverse计算,这里将上平台视为姿态不变体,来求解腿长,姿态补偿的关键其实就是求解 传感器得到的姿态变化以后,六个支链需要改变的长度,所以从公式上来说这个课题并不难理解。

clc

clear all

%close all

tic

% 上平台初始位置坐标 500

X = 0;

Y = 0;

Z = 500;

XP = 0; % 下平台 相对 上平台 的初始位置下移300,这里可以设置xyz三个方向位移量

YP = 0;

ZP = -300;

ROLL = 0.1; % 相对静平台的恣态 参数类型为 角度 cosd(roll)

PITCH = 0;

YAW = 0;

P = [ X+XP; Y+YP; Z+ZP ]; % 下平台圆心点 相对 上平台 的坐标

%--------------------------平台的基本尺寸----------------------------------

R = 150; % 上平台铰点的外接圆半径

r = 200; % 下平台铰点的外接圆半径

up_angle0 = -133.5; % 动平台铰点的安装角度 87度 33度

up_angle1 = -46.5;

up_angle2 = -13.5;

up_angle3 = 73.5;

up_angle4 = 106.5;

up_angle5 = 193.5;

down_angle0 = -110.0; % 静平台铰点的安装角度 α-down θ1为80° θ2为40度

down_angle1 = -70.0;

down_angle2 = 10.0;

down_angle3 = 50.0;

down_angle4 = 130.0;

down_angle5 = 170.0;

%----------上平台的6个铰点,在下平台坐标系中的位置矢量---------------------

bR1 = [ R*cosd( up_angle0 ); R*sind( up_angle0 ); Z];

bR2 = [ R*cosd( up_angle1 ); R*sind( up_angle1 ); Z];

bR3 = [ R*cosd( up_angle2 ); R*sind( up_angle2 ); Z];

bR4 = [ R*cosd( up_angle3 ); R*sind( up_angle3 ); Z ];

bR5 = [ R*cosd( up_angle4 ); R*sind( up_angle4 ); Z ];

bR6 = [ R*cosd( up_angle5 ); R*sind( up_angle5 ); Z ];

%----------静平台的6个铰点,在静平台坐标系中的位置矢量---------------------

Br1 = [ r*cosd( down_angle0 ) ; r*sind( down_angle0 ); 0 ];

Br2 = [ r*cosd( down_angle1 ) ; r*sind( down_angle1 ); 0 ];

Br3 = [ r*cosd( down_angle2 ) ; r*sind( down_angle2 ); 0 ];

Br4 = [ r*cosd( down_angle3 ) ; r*sind( down_angle3 ); 0 ];

Br5 = [ r*cosd( down_angle4 ) ; r*sind( down_angle4 ); 0 ];

Br6 = [ r*cosd( down_angle5 ) ; r*sind( down_angle5 ); 0 ];

%TransM = rotz(YAW) * roty(PITCH) * rotx(ROLL); % XYZ旋转矩阵

%TransM = rotx(ROLL) * roty(PITCH) * rotz(YAW) % ZYX旋转矩阵

TransM =...

[cosd(YAW), -sind(YAW),0; ...

sind(YAW),cosd(YAW),0; ...

0,0,1 ] * ...

[ cosd(PITCH), 0, sind(PITCH);...

0, 1, 0; ...

-sind(PITCH), 0, cosd(PITCH) ]* ...

[ 1, 0, 0;...

0, cosd(ROLL),-sind(ROLL);...

0, sind(ROLL),cosd(ROLL)];

%----------动平台的6个铰点,在静平台坐标系中的位置矢量,变换矩阵---------------------

BR1 = TransM * Br1 + P;

BR2 = TransM * Br2 + P;

BR3 = TransM * Br3 + P;

BR4 = TransM * Br4 + P;

BR5 = TransM * Br5 + P;

BR6 = TransM * Br6 + P;

%下平台铰点矢量减去上平台6个位置矢量,得到杆长矢量

L1 = BR1-bR1;

L2 = BR2-bR2;

L3 = BR3-bR3;

L4 = BR4-bR4;

L5 = BR5-bR5;

L6 = BR6-bR6;

%-----------求模,得到每个杆的杆长-----------------------------------------

LenL1 = norm(L1);

LenL2 = norm(L2);

LenL3 = norm(L3);

LenL4 = norm(L4);

LenL5 = norm(L5);

LenL6 = norm(L6);

toc % 显示计算时间

%-------------------------画出3D图-----------------------------------------

h=gca; % 把原来的图删掉,避免新图和旧的图相互重叠

delete(h);

figure(1); % hold on 开启

hold on;

view([1,1,1]); % 设定3D图的观察视角

axis equal; % XYZ轴显示比例相等

plot3( [0,300], [0,0], [0,0], '-b', 'LineWidth', 1 );% 在图中画出X轴,方便观察

plot3( 300, 0, 0, '>b' );

plot3( [0,0], [0,300], [0,0], '-r', 'LineWidth', 1 );% 在图中画出Y轴,方便观察

plot3( 0, 300, 0, '>r' );

plot3( [0,0], [0,0], [0,300], '-k', 'LineWidth', 1 );% 在图中画出Z轴,方便观察

plot3( 0, 0, 300, '>k' );

PBx0 = TransM * [ 0; 0; 0 ] + P;

PBx1 = TransM * [ 0+100; 0; 0 ] + P;

PBy0 = TransM * [ 0; 0; 0 ] + P;

PBy1 = TransM * [ 0; 0+100; 0 ] + P;

PBz0 = TransM * [ 0; 0; 0 ] + P;

PBz1 = TransM * [ 0; 0; 0+100 ] + P;

plot3( [PBx0(1),PBx1(1)], [PBx0(2),PBx1(2)], [PBx0(3),PBx1(3)], '-g', 'LineWidth', 1 );% 在图中画出X轴,方便观察

plot3( [PBy0(1),PBy1(1)], [PBy0(2),PBy1(2)], [PBy0(3),PBy1(3)], '-r', 'LineWidth', 1 );% 在图中画出Y轴,方便观察

plot3( [PBz0(1),PBz1(1)], [PBz0(2),PBz1(2)], [PBz0(3),PBz1(3)], '-k', 'LineWidth', 1 );% 在图中画出Z轴,方便观察

% 动平台用红色的图块,静平台用蓝色的图块

patch( [bR1(1),bR2(1),bR3(1),bR4(1),bR5(1),bR6(1)], [bR1(2),bR2(2),bR3(2),bR4(2),bR5(2),bR6(2)], [bR1(3),bR2(3),bR3(3),bR4(3),bR5(3),bR6(3)], 'c' );

patch( [BR1(1),BR2(1),BR3(1),BR4(1),BR5(1),BR6(1)], [BR1(2),BR2(2),BR3(2),BR4(2),BR5(2),BR6(2)], [BR1(3),BR2(3),BR3(3),BR4(3),BR5(3),BR6(3)], 'y' );

plot3(BR1(1),BR1(2),BR1(3), '.m', 'MarkerSize', 30); % 画出动平台上的6个铰点

plot3(BR2(1),BR2(2),BR2(3), '.m', 'MarkerSize', 30);

plot3(BR3(1),BR3(2),BR3(3), '.m', 'MarkerSize', 30);

plot3(BR4(1),BR4(2),BR4(3), '.m', 'MarkerSize', 30);

plot3(BR5(1),BR5(2),BR5(3), '.m', 'MarkerSize', 30);

plot3(BR6(1),BR6(2),BR6(3), '.m', 'MarkerSize', 30);

plot3( P(1), P(2), P(3), '.k', 'MarkerSize',10); % 画出动、静平台的圆心,方便观察

plot3( 0, 0, 0, '.k', 'MarkerSize',10);

plot3( [BR1(1),bR1(1)], [BR1(2),bR1(2)], [BR1(3),bR1(3)], '-k', 'LineWidth', 2 ); % 动、静平台的铰点连接,也就是连杆

plot3( [BR2(1),bR2(1)], [BR2(2),bR2(2)], [BR2(3),bR2(3)], '-k', 'LineWidth', 2 );

plot3( [BR3(1),bR3(1)], [BR3(2),bR3(2)], [BR3(3),bR3(3)], '-k', 'LineWidth', 2 );

plot3( [BR4(1),bR4(1)], [BR4(2),bR4(2)], [BR4(3),bR4(3)], '-k', 'LineWidth', 2 );

plot3( [BR5(1),bR5(1)], [BR5(2),bR5(2)], [BR5(3),bR5(3)], '-k', 'LineWidth', 2 );

plot3( [BR6(1),bR6(1)], [BR6(2),bR6(2)], [BR6(3),bR6(3)], '-k', 'LineWidth', 2 );

%-------------------------设置3D图的一些格式,方便观察---------------------

xlim([ -500,600 ]); % X轴固定显示范围

ylim([ -500,500 ]); % Y轴固定显示范围

zlim([ 0,900 ]); % Z轴固定显示范围

xlabel('X-axis / mm'); % X轴标识

ylabel('Y-axis / mm'); % Y轴标识

zlabel('Z-axis / mm'); % Z轴标识

str = ['LenL1 = ',num2str(LenL1)]; % 在图上显示每条连杆的长度,mm为单位

text(-300,200,900,[str,' mm']);

str = ['LenL2 = ',num2str(LenL2)];

text(-300,200,800,[str,' mm']);

str = ['LenL3 = ',num2str(LenL3)];

text(-300,200,700,[str,' mm']);

str = ['LenL4 = ',num2str(LenL4)];

text(-300,200,600,[str,' mm']);

str = ['LenL5 = ',num2str(LenL5)];

text(-300,200,500,[str,' mm']);

str = ['LenL6 = ',num2str(LenL6)];

text(-300,200,400,[str,' mm']);

text( Br1(1), Br1(2)-50, '1' ); % 在静平台的铰点旁边,显示连杆的序号

text( Br2(1)+50, Br2(2)-50, '2' );

text( Br3(1)+50, Br3(2)-50, '3' );

text( Br4(1)+50, Br4(2)+50, '4' );

text( Br5(1)+50, Br5(2)+50, '5' );

text( Br6(1)-50, Br6(2)-50, '6' );

4551

4551

被折叠的 条评论

为什么被折叠?

被折叠的 条评论

为什么被折叠?