一、简介

相位偏折术(Phase Deflectometry)是一种先进的光学测量技术,结合了相位测量偏折术,测量镜面物体,(Phase-Measuring Deflectometry, PMD)和结构光投影技术,主要用于高精度、非接触式的三维表面形貌检测 。

干涉法局限性:

- 测量自由面型的镜面物体时,干涉法所需要的光学补偿原件制作复杂且昂贵;

- 回程误差,干涉法很难快速标定;

- 测量环境苛刻,不适合干涉法测量,因为轻微抖动、温度变化,会给测量记过带来很大误差;

解决:PMD,相位偏折术,对环境不敏感,没有回程误差,因而标定相对简单,可以测量自由曲面。其实偏折术系统跟结构光系统是非常相似的,回顾下它的重建流程:

- 标定相机,以及屏幕、相机位置关系

- 使用屏幕投影条纹(结构光使用投影仪)

- 解码获取表面梯度(结构光直接获取高度)

- 梯度积分获取高度信息

综述 I 用于获取镜面 3D 形状的相位测量偏转法:对最新技术回顾 - 哔哩哔哩 (bilibili.com)

structured_light_partially_specular

相位偏折术原理概述 - 3D视觉工坊 - 博客园 (cnblogs.com)

二、基本原理

原理:

- 显示屏显示计算机生成的结构光条纹;

- 相机通过待测镜面表面拍摄显示屏上条纹的镜像;

- 如果镜面表面不平整的话,则拍摄到的条纹会产生相应的变形

详细原理:

推导如下:

-

相位偏折术通过投射特定的光栅图案(如正弦条纹)到被测物体表面,相机捕捉因表面形变导致的条纹畸变,进而解算相位变化,重建表面斜率或高度信息。

-

关键步骤:

-

图案投影:投射多组相位移动的光栅图案(通常使用计算机屏幕或投影仪)。

-

图像采集:相机从不同角度捕获受物体表面调制后的变形条纹。

-

相位解调:通过相位移动算法(如四步相移法)提取绝对相位。

-

几何重建:根据相位变化与表面法向的关系,结合系统标定参数,计算表面三维形貌

-

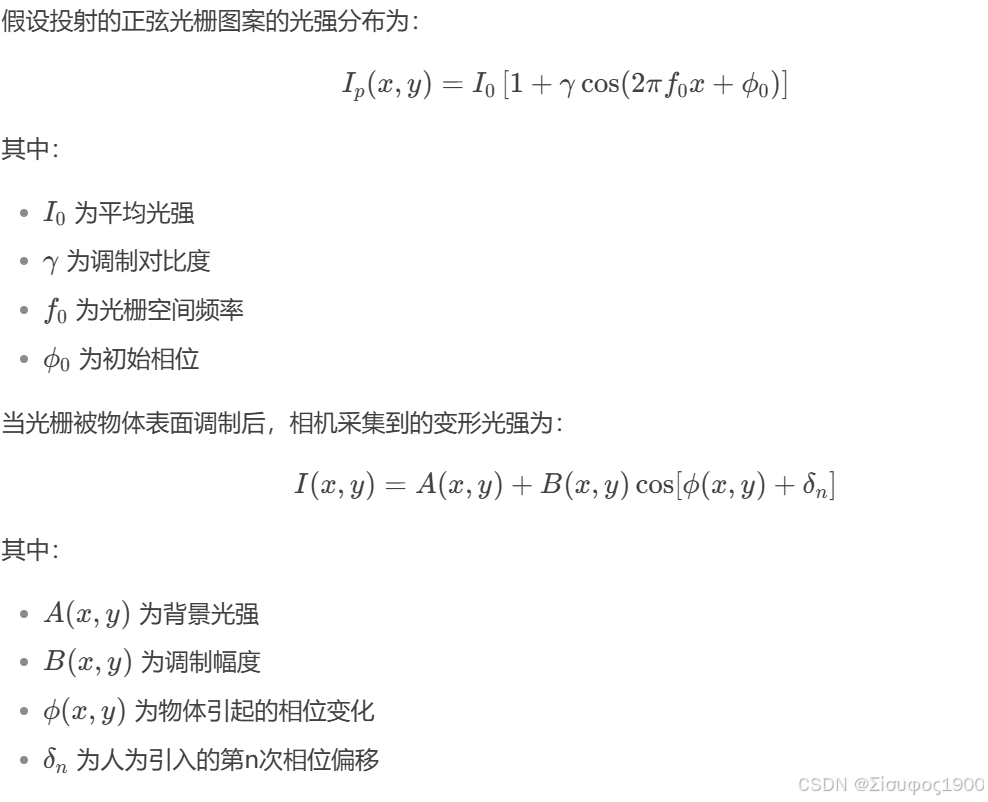

数学推导:

相位偏移法是一种通过投射多幅相位移动的结构光图案(如正弦光栅)并解调相位信息,从而恢复物体表面三维形貌的技术。其核心推导包括 光强模型建立、相位计算、相位解包裹、相位-高度映射 等步骤。以下是详细推导过程

光强模型建立

相位计算(以四步相移法为例)

相位解包裹

相位-高度映射

高度重建

一般化 N 步相移公式

改进方法

-

增加相移步数(如 12 步法)提高抗噪能力。

-

使用格雷码+相移 结合绝对相位解算。

-

深度学习去噪:用神经网络优化相位计算。

误差来源

-

非线性响应:相机或投影仪的 Gamma 校正导致非理想正弦条纹。

-

环境光干扰:背景光影响 A(x,y)A(x,y) 的稳定性。

-

振动噪声:动态测量时引入相位误差。

-

解包裹错误:在复杂表面或遮挡区域可能跳变

技术特点

-

高精度:亚微米级分辨率,适用于光学元件、精密加工表面的检测。

-

全视野测量:可一次性测量大范围区域,无需逐点扫描。

-

动态能力:适合动态表面或振动环境下的实时测量。

-

无需喷涂:对反射表面(如镜面、金属)直接测量,无需喷显影剂

与传统方法的对比

应用领域

-

光学元件检测:透镜、反射镜的面形误差(如RMS、PV值)。

-

工业制造:汽车、航空航天部件的表面质量评估。

-

半导体:晶圆、光刻掩模板的平整度测量。

-

生物医学:角膜、人工关节的表面分析。

-

系统标定:需精确校准投影仪-相机几何关系,误差敏感。

-

环境光干扰:强光环境下需屏蔽或使用主动光源。

-

高反射表面:可能需偏振滤波或多曝光策略抑制过曝。

-

算法优化:深度学习正被用于相位解算和噪声抑制。

三、迈克尔逊干涉法和相位偏移法对比

四、Halcon案例

* This example shows how to improve defect detection on partially

* specular surfaces using deflectometry.

*

* For partially specular surfaces it is often the case that multiple

* artifacts are detected and defects are hence not clearly found. In

* these scenarios, it is recommended to use the

* pattern_type='single_stripe' with a suitable single_stripe_width.

*

* The following example shows the improved defect detection that can

* be achieved with this pattern type in comparison to the default type.

* For a detailed example of the workflow of detection with deflectometry,

* please refer to the example 'structured_light_tap_collar.hdev'.

*

dev_update_off ()

dev_close_window ()

dev_open_window (0, 0, 600, 450, 'black', WindowHandle1)

set_display_font (WindowHandle1, 14, 'mono', 'true', 'false')

*

dev_disp_intro_text ()

stop ()

dev_set_draw ('margin')

dev_set_line_width (3)

*

* 1. Create the structured light model with the default pattern_type

* gray_code_and_phase_shift and set its necessary parameters.

create_structured_light_model ('deflectometry', StructuredLightModel)

*

PatternWidth := 1600

PatternHeight := 1200

MinStripeWidth := 32

MinGrayDifference := 0

Persistence := 'true'

Normalization := 'inverted_pattern'

set_structured_light_model_param (StructuredLightModel, ['pattern_width','pattern_height','min_stripe_width','min_gray_difference','normalization','persistence'], [PatternWidth,PatternHeight,MinStripeWidth,MinGrayDifference,Normalization,Persistence])

* 2. Acquire and decode images with this model and visualize the

* resulting defect image.

*

* Generate the pattern images.

gen_structured_light_pattern (PatternImages, StructuredLightModel)

* Read in the camera images and decode them.

count_obj (PatternImages, Number)

gen_empty_obj (CameraImages)

for Index := 1 to Number by 1

read_image (Image, 'structured_light/varnished_metal_sheet/varnished_metal_sheet_' + Index$'02' + '.png')

concat_obj (CameraImages, Image, CameraImages)

endfor

stop ()

* Decode the structured light pattern.

decode_structured_light_pattern (CameraImages, StructuredLightModel)

* Get the binarized images.

get_structured_light_object (BinarizedImages, StructuredLightModel, 'binarized_image')

stop ()

InspectSegmentation := 'false'

*

dev_open_window (0, 609, 600, 450, 'black', WindowHandle2)

set_display_font (WindowHandle2, 14, 'mono', 'true', 'false')

*

* 3. Check whether the bright/dark decoding is correct.

* The idea here is to call the procedure and check

* whether the decoded bright regions match the bright

* regions on the camera images. If they don't match,

* as in this example, it is an indication that the

* decoding was wrong. This is usually because the surface

* is partially specular and indicates that 'single_stripe'

* pattern should be used.

* Please uncomment the following lines to run the check.

if (InspectSegmentation == 'true')

select_obj (CameraImages, CameraImagesGC, [1:2:28])

dev_set_window (WindowHandle2)

dev_clear_window ()

Text := 'The decoded bright regions for min_gray_difference = 0.'

Text[1] := ' '

Text[2] := 'If the visualized region does not match the bright region on the'

Text[3] := 'camera image, then the decoding was incorrect.'

dev_disp_text (Text, 'window', 'top', 'left', 'white', 'box', 'false')

gen_structured_light_pattern (PatternImages, StructuredLightModel)

decode_structured_light_pattern (CameraImages, StructuredLightModel)

get_structured_light_object (BinarizedImages, StructuredLightModel, 'binarized_image')

structured_light_inspect_segmentation (CameraImagesGC, BinarizedImages, WindowHandle1)

endif

* Visualize the first 2 camera images to show the effect of the used

* inverted_pattern normalization.

select_obj (CameraImages, CameraImage1, 1)

select_obj (CameraImages, CameraImage2, 2)

dev_set_window (WindowHandle1)

dev_display (CameraImage1)

dev_disp_text ('First camera image.', 'window', 12, 12, 'black', [], [])

dev_set_window (WindowHandle2)

dev_display (CameraImage2)

dev_disp_text ('Second camera image that corresponds to the inverted pattern\nof the first pattern image.', 'window', 12, 12, 'black', [], [])

dev_open_window (510, 0, 900, 220, 'black', WindowHandle3)

set_display_font (WindowHandle3, 14, 'mono', 'true', 'false')

dev_disp_inverted_pattern_text ()

stop ()

*

dev_set_window (WindowHandle1)

dev_clear_window ()

dev_set_line_width (3)

convert_image_type (CameraImage1, CamImage1, 'real')

convert_image_type (CameraImage2, CamImage2, 'real')

sub_image (CamImage1, CamImage2, DiffImage, 1, 0)

dev_display (DiffImage)

dev_disp_text ('Difference image of the first two camera images\nwith region where the first image is brighter\nthan the second.', 'window', 12, 12, 'black', [], [])

threshold (DiffImage, BrighterInFirstImage, 0, 255)

dev_display (BrighterInFirstImage)

dev_set_window (WindowHandle2)

dev_clear_window ()

dev_display (BinarizedImages)

dev_disp_text ('The corresponding binarized image with partially wrong\nidentified white and black pixels.', 'window', 12, 12, 'black', [], [])

dev_set_window (WindowHandle3)

dev_disp_problem_text ()

stop ()

dev_close_window ()

* Get the computed correspondence images.

get_structured_light_object (CorrespondenceImages, StructuredLightModel, 'correspondence_image')

dev_set_window (WindowHandle1)

dev_clear_window ()

dev_display (CorrespondenceImages)

dev_disp_text ('A wrongly decoded correspondence image.', 'window', 12, 12, 'black', [], [])

gen_rectangle1 (ProblematicRegion, 130, 1050, 900, 1270)

dev_display (ProblematicRegion)

dev_set_window (WindowHandle2)

dev_disp_wrong_correspondence ()

stop ()

* Get the defect image and scale it.

get_structured_light_object (DefectImage, StructuredLightModel, 'defect_image')

scale_image_range (DefectImage, ScaledDefectImage, 0, 4)

dev_set_window (WindowHandle1)

dev_clear_window ()

dev_display (ScaledDefectImage)

dev_display (ProblematicRegion)

dev_disp_text ('Scaled defect image with default pattern_type.', 'window', 12, 12, 'black', [], [])

dev_set_window (WindowHandle2)

dev_disp_wrong_defect ()

stop ()

*

*

* 4. Create another structured light model with the pattern_type

* single_stripe and set the necessary parameters.

create_structured_light_model ('deflectometry', StructuredLightModelSS)

PatternType := 'single_stripe'

SingleStripeWidth := 64

set_structured_light_model_param (StructuredLightModelSS, ['pattern_width','pattern_height','min_stripe_width','min_gray_difference','pattern_type','single_stripe_width','persistence'], [PatternWidth,PatternHeight,MinStripeWidth,MinGrayDifference,PatternType,SingleStripeWidth,Persistence])

* 5. Acquire and decode images with this improved model and visualize

* the improved defect image.

*

* Generate the pattern images.

gen_structured_light_pattern (PatternImagesSS, StructuredLightModelSS)

dev_open_window (510, 0, 900, 220, 'black', WindowHandle3)

set_display_font (WindowHandle3, 14, 'mono', 'true', 'false')

dev_disp_single_stripe_text ()

* Read in the camera images and decode them.

dev_set_window (WindowHandle1)

SingleStripesNum := round((PatternWidth + PatternHeight) / real(SingleStripeWidth))

count_obj (PatternImagesSS, NumberSS)

gen_empty_obj (CameraImagesSS)

for Index := 1 to NumberSS by 1

select_obj (PatternImagesSS, Image, Index)

read_image (CameraImage, 'structured_light/varnished_metal_sheet/varnished_metal_sheet_single_stripe_' + Index$'02' + '.png')

if (Index <= SingleStripesNum)

* Display the single stripe image.

dev_set_window (WindowHandle1)

dev_display (Image)

dev_disp_text ('Single stripe image.', 'window', 'top', 'left', 'black', [], [])

* Display the corresponding camera image.

dev_set_window (WindowHandle2)

dev_display (CameraImage)

dev_disp_text ('Corresponding camera image.', 'window', 'top', 'left', 'black', [], [])

wait_seconds (0.1)

endif

concat_obj (CameraImagesSS, CameraImage, CameraImagesSS)

endfor

stop ()

dev_set_window (WindowHandle3)

dev_close_window ()

decode_structured_light_pattern (CameraImagesSS, StructuredLightModelSS)

* Get the computed correspondence images.

get_structured_light_object (CorrespondenceImagesSS, StructuredLightModelSS, 'correspondence_image')

dev_disp_comparison (CorrespondenceImagesSS, CorrespondenceImages, WindowHandle1, WindowHandle2, 'Correspondence image with single_stripe shows\n - expected gradual change in gray values,\n - no abrupt changes.', 'Correspondence image with default pattern_type')

stop ()

* Get the defect image and scale it.

get_structured_light_object (DefectImageSS, StructuredLightModelSS, 'defect_image')

scale_image_range (DefectImageSS, ScaledDefectImageSS, 0, 4)

dev_disp_comparison (ScaledDefectImageSS, ScaledDefectImage, WindowHandle1, WindowHandle2, 'Scaled defect image with single_stripe shows\n - more pronounced defects in comparison to the background,\n - no problematic regions where defects are not detected.', 'Scaled defect image with default pattern_type')

2505

2505

被折叠的 条评论

为什么被折叠?

被折叠的 条评论

为什么被折叠?