These objects are used to model the physical structure, define the solver region, any sources of light or doping/generation regions as well as monitors to collect data. The pages provide detailed descriptions of each simulation object. Simulation objects can be added by clicking on the corresponding icon in the GUI.

Structures

Primitives:

Triangle - Simulation Object

FDTD MODE DGTD CHARGE HEAT FEEM

Triangular objects denote physical objects that appear triangular from above. For 2D simulations, these objects represent triangles while in 3D these objects are extruded in the z direction to a specific height. They are actually polygon objects, with the number of vertices set to 3.

Setting the vertices of the polygon object

The vertices of the polygon object can be edited by

- moving them with the mouse,

- manually editing the x,y location of each vertex in the polygon property editor,

- script command

For complex shapes, scripting in the structure group is usually best. Once the script has calculated the x,y vertex positions, they can be loaded into the polygon object with a single set("vertices",V); command. For example, use the following code to create an octagon shaped object.

# octagon properties

n_sides=8;

r=1e-6;

# x,y position of each corner

theta=linspace(0,360,n_sides+1);

theta=theta(1:n_sides);

x=r*cos(theta*pi/180);

y=r*sin(theta*pi/180);

# combine x,y into one vertices matrix

V=matrix(n_sides,2);

V(1:n_sides,1)=x(1:n_sides);

V(1:n_sides,2)=y(1:n_sides);

# add polygon object and set the vertices

addpoly;

set("vertices",V);

To get the polygon vertices, use the following command. The vertices will be returned in an Nx2 matrix. The columns of this matrix correspond to the X,Y positions of each vertex.

V=get("vertices");

?size(V);

To modify a polygon vertex, you must get the vertices matrix, modify the vertex matrix as desired, then re-apply it to the polygon object:

V=get("vertices");

V(1,1)=V(1,1)+1e-6; # change the x position of the first vertex by 1um.

set("vertices",V);

Geometry tab

- X, Y, Z: The center position of the object

- Z MIN, Z MAX: Z min, Z max position

- Z SPAN: Z span of the object

- ADD, DELETE: Add, delete vertices

Material tab

The material options are as follows:

- MATERIAL: This field can be set to any material included in the material database. It is possible to include new materials in the database, or edit the materials already included. See the material database section for more information.

- OVERRIDE MESH ORDER FROM MATERIAL DATABASE: Select to override the mesh order from the material database and manually set a mesh order. The mesh order is used by the simulation engine to select which material to use when two materials overlap. See the mesh order (optical) or mesh order (electrical) section for more details.

- MESH ORDER: Set the mesh order in this field if the OVERRIDE MESH ORDER FROM MATERIAL DATABASE option is selected. If the option is not selected, the field displays the material's default mesh order from the database. For example, a material of mesh order 1 will take precedence over a material of mesh order 2.

The following only applies to MODE and FDTD:

If <Object defined dielectric> is selected, then the INDEX property must be set.

- INDEX: The refractive index of the structure, when the material type is <Object defined dielectric>. The index must be greater than one.

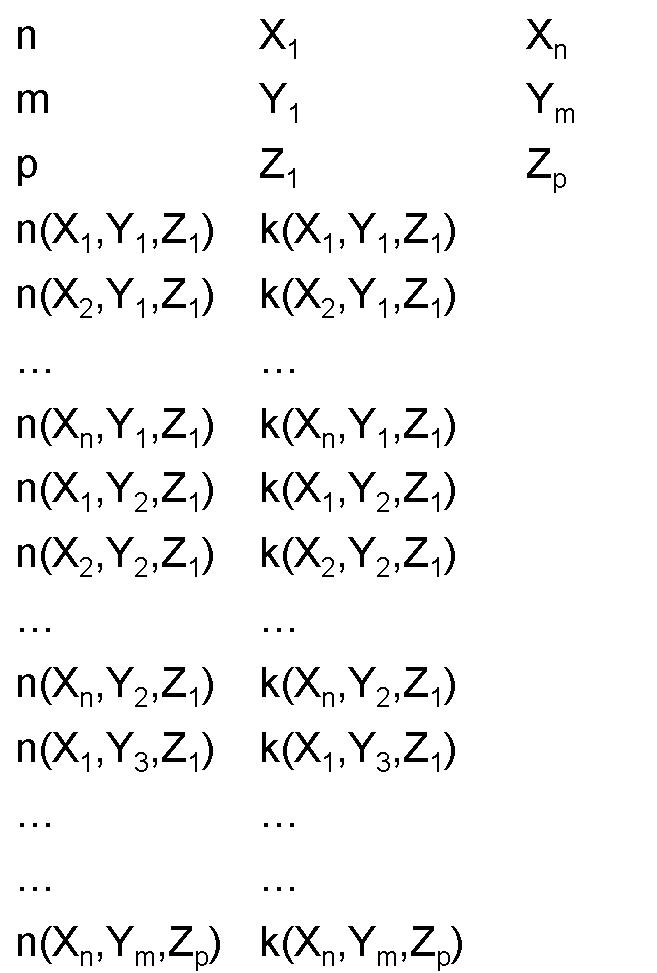

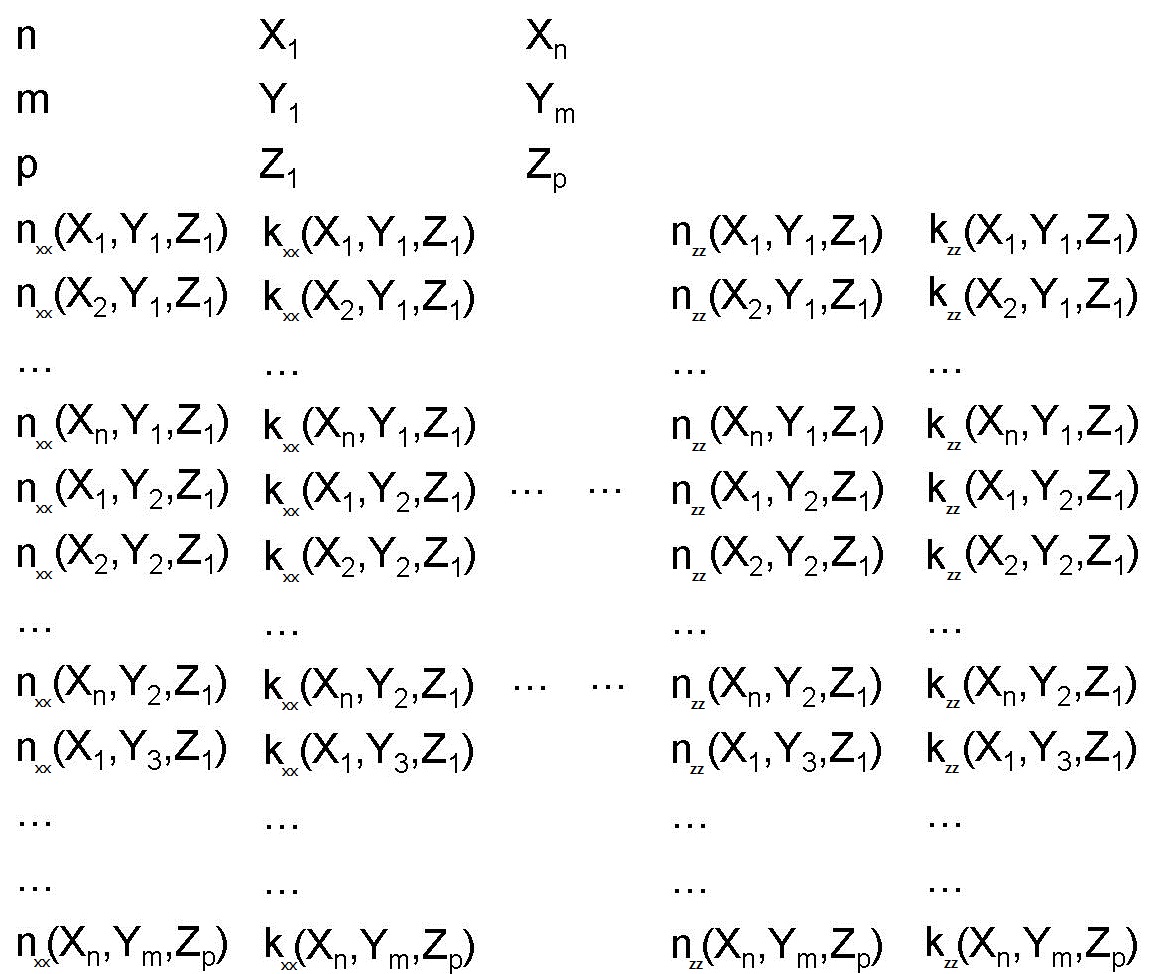

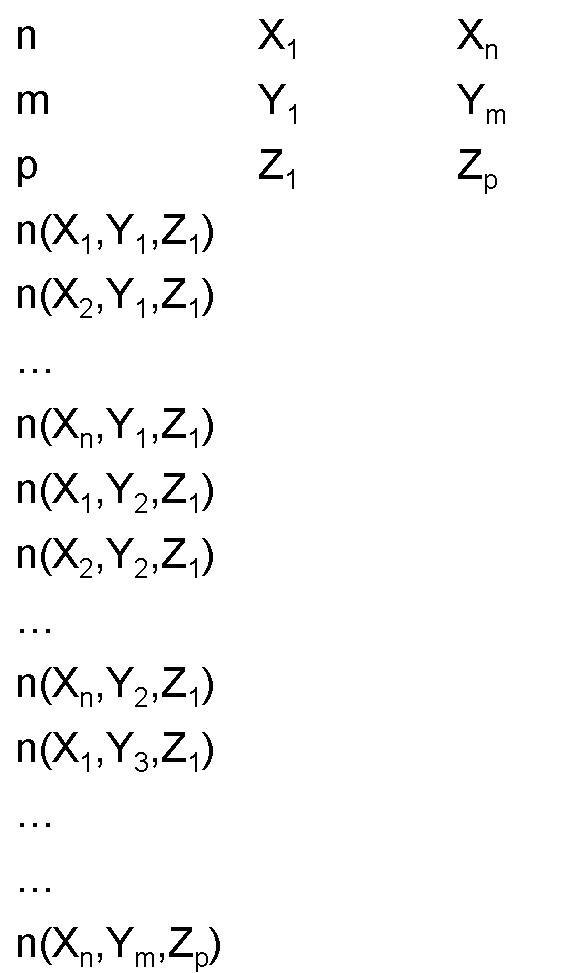

- Anisotropic index: To specify an anisotropic refractive index, use a semicolon to separate the diagonal xx,yy,zz indices. Eg. 1;1.5;1

- Spatially varying index: It is possible to specify a spatially varying refractive index by entering an equation of the variables x,y,z in this field. Eg. 2+0.1*x will create an object where the refractive index increases in the X direction. The units of the spatial variables (x,y,z) must be set with the 'INDEX UNITS' property described below. The variables x,y,z will be zero in the center of the object. When using an equation in this field, consider using a mesh override region to control the simulation mesh size. For more information on entering equations, see the Equation interpreter section.

- INDEX UNITS: Only relevant when specifying a spatially varying equation in the INDEX properly described above. Specify the units (nm, um, m) of the x,y,z position variables.

- GRID ATTRIBUTE NAME: Enter the name of the grid attribute that applies to this object, see the grid attribute section

The following only applies to CHARGE, HEAT, FEEM, DGTD:

If the material chosen from the drop down menu is a binary alloy consisting of two semiconductors, then there will be an additional property, namely, the "composition fraction" to set as well.

- COMPOSITION FRACTION: This is x, the fraction of the semiconductor in the alloy. x can either take a fixed value or vary.

The user can see which semiconductor has fraction x and which has fraction (1-x) shown in a line above this drop down menu.

- FIXED: This means that fraction x will be a constant value between 0 and 1.

- LINEAR X/Y/Z: This means that the composition fraction x will vary as a function x or y or z. In this case, user can specify the min and max fraction values for the min and max spatial points and the fraction will be interpolated linearly in between. x,y,z here are those of the unrotated object. x,y,z are local to the object.

- EQUATION: The user can enter an equation for the fraction that varies with u,v and w. u is (x-x0), v is (y-y0) and w is (z-z0) where x0, y0 and z0 are the center coordinates of the object. This means that u,v and w are local to the object.

Rotation tab

Rotate objects by setting the following variables:

- FIRST, SECOND, THIRD AXES: Select rotation axis. Up to three different rotations can be applied.

- ROTATION 1,2,3: The rotation of the object in a clockwise direction about each axis, measured in degrees.

Graphical Rendering tab

The graphical rendering tab is used to change how objects are drawn in the layout editor. The options are:

- RENDER TYPE: The options for drawing the objects are detailed or wireframe. Detailed objects are shaded and their transparency can be set using OVERRIDE COLOR OPACITY FROM MATERIAL DATABASE.

- DETAIL: This is a slider which takes values between 0 and 1. By default it is set to 0.5. Higher detail shows more detail, but increases the time required to draw objects. This setting has no effect on the simulation.

- OVERRIDE COLOR OPACITY FROM MATERIAL DATABASE: When unselected the opacity is determined from the material database. When selected, you can specify a value for ALPHA between 0 (transparent) and 1 (opaque) for the object, depending on how transparent you want the object to be.

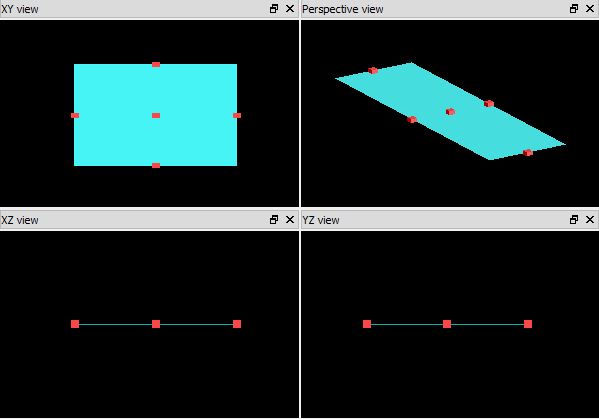

Rectangle - Simulation Object

FDTD MODE DGTD CHARGE HEAT FEEM

Rectangular regions denote physical objects that appear rectangular from above. For 2D simulations, these objects represent rectangles while in 3D these objects are extruded to a specific height.

Geometry tab

- X, Y, Z: The center position of the object

- X MIN, X MAX: X min, X max position

- Y MIN, Y MAX: Y min, Y max position

- Z MIN, Z MAX: Z min, Z max position

- X SPAN, Y SPAN, Z SPAN: X, Y, Z span of the object

Material tab

The material options are as follows:

- MATERIAL: This field can be set to any material included in the material database. It is possible to include new materials in the database, or edit the materials already included. See the material database section for more information.

- OVERRIDE MESH ORDER FROM MATERIAL DATABASE: Select to override the mesh order from the material database and manually set a mesh order. The mesh order is used by the simulation engine to select which material to use when two materials overlap. See the mesh order (optical) or mesh order (electrical) section for more details.

- MESH ORDER: Set the mesh order in this field if the OVERRIDE MESH ORDER FROM MATERIAL DATABASE option is selected. If the option is not selected, the field displays the material's default mesh order from the database. For example, a material of mesh order 1 will take precedence over a material of mesh order 2.

The following only applies to MODE and FDTD:

If <Object defined dielectric> is selected, then the INDEX property must be set.

- INDEX: The refractive index of the structure, when the material type is <Object defined dielectric>. The index must be greater than one.

-

-

- Anisotropic index: To specify an anisotropic refractive index, use a semicolon to separate the diagonal xx,yy,zz indices. Eg. 1;1.5;1

- Spatially varying index: It is possible to specify a spatially varying refractive index by entering an equation of the variables x,y,z in this field. Eg. 2+0.1*x will create an object where the refractive index increases in the X direction. The units of the spatial variables (x,y,z) must be set with the 'INDEX UNITS' property described below. The variables x,y,z will be zero in the center of the object. When using an equation in this field, consider using a mesh override region to control the simulation mesh size. For more information on entering equations, see the Equation interpreter section.

-

- INDEX UNITS: Only relevant when specifying a spatially varying equation in the INDEX properly described above. Specify the units (nm, um, m) of the x,y,z position variables.

- GRID ATTRIBUTE NAME: Enter the name of the grid attribute that applies to this object, see the grid attribute section

The following only applies to CHARGE, HEAT, FEEM, DGTD:

If the material chosen from the drop down menu is a binary alloy consisting of two semiconductors, then there will be an additional property, namely, the "composition fraction" to set as well.

- COMPOSITION FRACTION: This is x, the fraction of the semiconductor in the alloy. x can either take a fixed value or vary.

The user can see which semiconductor has fraction x and which has fraction (1-x) shown in a line above this drop down menu.

- FIXED: This means that fraction x will be a constant value between 0 and 1.

- LINEAR X/Y/Z: This means that the composition fraction x will vary as a function x or y or z. In this case, user can specify the min and max fraction values for the min and max spatial points and the fraction will be interpolated linearly in between. x,y,z here are those of the unrotated object. x,y,z are local to the object.

- EQUATION: The user can enter an equation for the fraction that varies with u,v and w. u is (x-x0), v is (y-y0) and w is (z-z0) where x0, y0 and z0 are the center coordinates of the object. This means that u,v and w are local to the object.

Rotation tab

Rotate objects by setting the following variables:

- FIRST, SECOND, THIRD AXES: Select rotation axis. Up to three different rotations can be applied.

- ROTATION 1,2,3: The rotation of the object in a clockwise direction about each axis, measured in degrees.

Graphical Rendering tab

The graphical rendering tab is used to change how objects are drawn in the layout editor. The options are:

- RENDER TYPE: The options for drawing the objects are detailed or wireframe. Detailed objects are shaded and their transparency can be set using OVERRIDE COLOR OPACITY FROM MATERIAL DATABASE.

- DETAIL: This is a slider which takes values between 0 and 1. By default it is set to 0.5. Higher detail shows more detail, but increases the time required to draw objects. This setting has no effect on the simulation.

- OVERRIDE COLOR OPACITY FROM MATERIAL DATABASE: When unselected the opacity is determined from the material database. When selected, you can specify a value for ALPHA between 0 (transparent) and 1 (opaque) for the object, depending on how transparent you want the object to be.

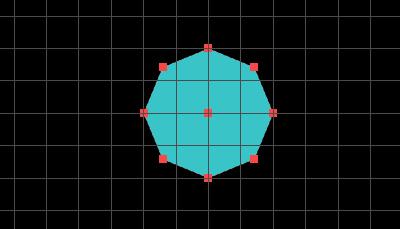

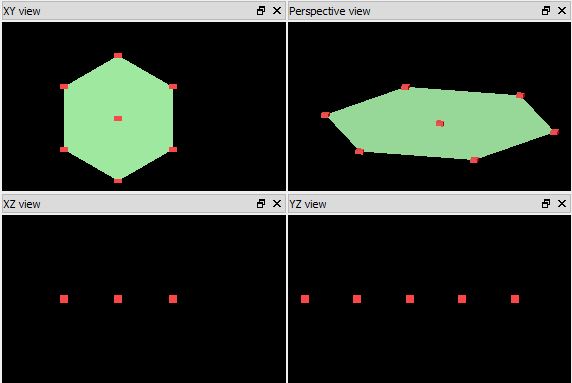

Polygon - Simulation Object

FDTD MODE DGTD CHARGE HEAT FEEM

This section describes how to set and get the vertex positions of a polygon object. Polygons allow the user to define a custom object with a variable number of vertices. The location of each vertex can be independently positioned within a plane, and the vertices are connected with straight lines. For 3D simulations, the object is extruded in the z dimension. In DEVICE, the vertices have to be entered in a counter clock wise manner for the structure to be defined and meshed properly.

Setting the vertices of the polygon object

The vertices of the polygon object can be edited by

- moving them with the mouse,

- manually editing the x,y location of each vertex in the polygon property editor,

- script command

For complex shapes, scripting in the structure group is usually best. Once the script has calculated the x,y vertex positions, they can be loaded into the polygon object with a single set("vertices",V); command. For example, use the following code to create an octagon shaped object.

# octagon properties

n_sides=8;

r=1e-6;

# x,y position of each corner

theta=linspace(0,360,n_sides+1);

theta=theta(1:n_sides);

x=r*cos(theta*pi/180);

y=r*sin(theta*pi/180);

# combine x,y into one vertices matrix

V=matrix(n_sides,2);

V(1:n_sides,1)=x(1:n_sides);

V(1:n_sides,2)=y(1:n_sides);

# add polygon object and set the vertices

addpoly;

set("vertices",V);

NOTE: Getting and modifying polygon vertices

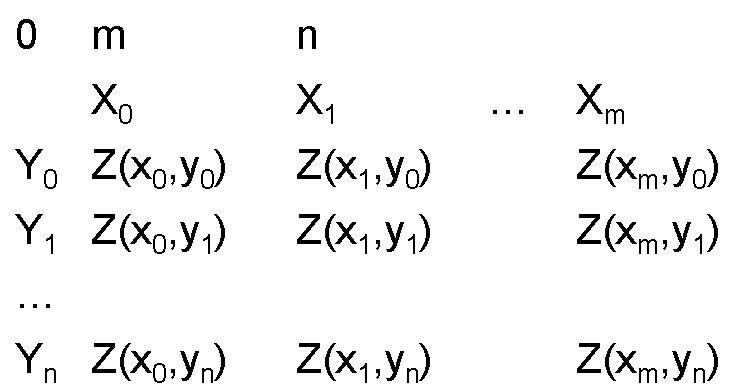

To get the polygon vertices, use the following command. The vertices will be returned in an Nx2 matrix. The columns of this matrix correspond to the X,Y positions of each vertex.

V=get("vertices");

?size(V);

To modify a polygon vertex, you must get the vertices matrix, modify the vertex matrix as desired, then re-apply it to the polygon object:

V=get("vertices");

V(1,1)=V(1,1)+1e-6; # change the x position of the first vertex by 1um.

set("vertices",V);

Geometry tab

- X, Y, Z: The center position of the object

- Z MIN, Z MAX: Z min, Z max position

- Z SPAN: Z span of the object

- ADD, DELETE: Add, delete vertices

Material tab

The material options are as follows:

- MATERIAL: This field can be set to any material included in the material database. It is possible to include new materials in the database, or edit the materials already included. See the material database section for more information.

- OVERRIDE MESH ORDER FROM MATERIAL DATABASE: Select to override the mesh order from the material database and manually set a mesh order. The mesh order is used by the simulation engine to select which material to use when two materials overlap. See the mesh order (optical) or mesh order (electrical) section for more details.

- MESH ORDER: Set the mesh order in this field if the OVERRIDE MESH ORDER FROM MATERIAL DATABASE option is selected. If the option is not selected, the field displays the material's default mesh order from the database. For example, a material of mesh order 1 will take precedence over a material of mesh order 2.

The following only applies to MODE and FDTD:

- If <Object defined dielectric> is selected, then the INDEX property must be set.

- INDEX: The refractive index of the structure, when the material type is <Object defined dielectric>. The index must be greater than one.

- Anisotropic index: To specify an anisotropic refractive index, use a semicolon to separate the diagonal xx,yy,zz indices. Eg. 1;1.5;1

- Spatially varying index: It is possible to specify a spatially varying refractive index by entering an equation of the variables x,y,z in this field. Eg. 2+0.1*x will create an object where the refractive index increases in the X direction. The units of the spatial variables (x,y,z) must be set with the 'INDEX UNITS' property described below. The variables x,y,z will be zero in the center of the object. When using an equation in this field, consider using a mesh override region to control the simulation mesh size. For more information on entering equations, see the Equation interpreter section.

- INDEX UNITS: Only relevant when specifying a spatially varying equation in the INDEX properly described above. Specify the units (nm, um, m) of the x,y,z position variables.

- GRID ATTRIBUTE NAME: Enter the name of the grid attribute that applies to this object, see the grid attribute section

The following only applies to CHARGE, HEAT, FEEM, DGTD:

If the material chosen from the drop down menu is a binary alloy consisting of two semiconductors, then there will be an additional property, namely, the "composition fraction" to set as well.

- COMPOSITION FRACTION: This is x, the fraction of the semiconductor in the alloy. x can either take a fixed value or vary.

The user can see which semiconductor has fraction x and which has fraction (1-x) shown in a line above this drop down menu.

- FIXED: This means that fraction x will be a constant value between 0 and 1.

- LINEAR X/Y/Z: This means that the composition fraction x will vary as a function x or y or z. In this case, user can specify the min and max fraction values for the min and max spatial points and the fraction will be interpolated linearly in between. x,y,z here are those of the unrotated object. x,y,z are local to the object.

- EQUATION: The user can enter an equation for the fraction that varies with u,v and w. u is (x-x0), v is (y-y0) and w is (z-z0) where x0, y0 and z0 are the center coordinates of the object. This means that u,v and w are local to the object.

Rotation tab

Rotate objects by setting the following variables:

- FIRST, SECOND, THIRD AXES: Select rotation axis. Up to three different rotations can be applied.

- ROTATION 1,2,3: The rotation of the object in a clockwise direction about each axis, measured in degrees.

Graphical Rendering tab

The graphical rendering tab is used to change how objects are drawn in the layout editor. The options are:

- RENDER TYPE: The options for drawing the objects are detailed or wireframe. Detailed objects are shaded and their transparency can be set using OVERRIDE COLOR OPACITY FROM MATERIAL DATABASE.

- DETAIL: This is a slider which takes values between 0 and 1. By default it is set to 0.5. Higher detail shows more detail, but increases the time required to draw objects. This setting has no effect on the simulation.

- OVERRIDE COLOR OPACITY FROM MATERIAL DATABASE: When unselected the opacity is determined from the material database. When selected, you can specify a value for ALPHA between 0 (transparent) and 1 (opaque) for the object, depending on how transparent you want the object to be.

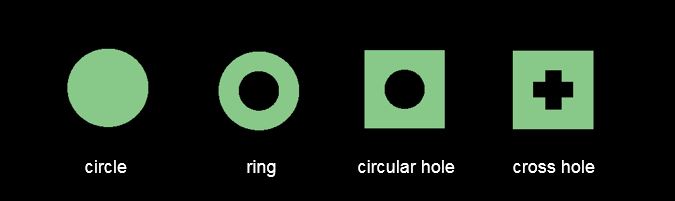

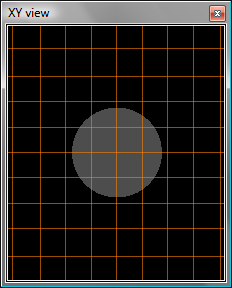

Circle - Simulation Object

FDTD MODE DGTD CHARGE HEAT FEEM

Circles denote physical objects which appear circular or ellipsoid from above. They are either circles/ellipses in 2D, or circular/ellipsoid cylinders in 3D.

Geometry tab

- X, Y, Z: The center position of the object

- Z MIN, Z MAX: Z min, Z max position

- Z SPAN: Z span of the object

- RADIUS: Radius of the object

- MAKE ELLIPSOID: If this box is checked, a second radius can be defined

Material tab

The material options are as follows:

- MATERIAL: This field can be set to any material included in the material database. It is possible to include new materials in the database, or edit the materials already included. See the material database section for more information.

- OVERRIDE MESH ORDER FROM MATERIAL DATABASE: Select to override the mesh order from the material database and manually set a mesh order. The mesh order is used by the simulation engine to select which material to use when two materials overlap. See the mesh order (optical) or mesh order (electrical) section for more details.

- MESH ORDER: Set the mesh order in this field if the OVERRIDE MESH ORDER FROM MATERIAL DATABASE option is selected. If the option is not selected, the field displays the material's default mesh order from the database. For example, a material of mesh order 1 will take precedence over a material of mesh order 2.

The following only applies to MODE and FDTD:

If <Object defined dielectric> is selected, then the INDEX property must be set.

- INDEX: The refractive index of the structure, when the material type is <Object defined dielectric>. The index must be greater than one.

-

-

- Anisotropic index: To specify an anisotropic refractive index, use a semicolon to separate the diagonal xx,yy,zz indices. Eg. 1;1.5;1

- Spatially varying index: It is possible to specify a spatially varying refractive index by entering an equation of the variables x,y,z in this field. Eg. 2+0.1*x will create an object where the refractive index increases in the X direction. The units of the spatial variables (x,y,z) must be set with the 'INDEX UNITS' property described below. The variables x,y,z will be zero in the center of the object. When using an equation in this field, consider using a mesh override region to control the simulation mesh size. For more information on entering equations, see the Equation interpreter section.

-

- INDEX UNITS: Only relevant when specifying a spatially varying equation in the INDEX properly described above. Specify the units (nm, um, m) of the x,y,z position variables.

- GRID ATTRIBUTE NAME: Enter the name of the grid attribute that applies to this object, see the grid attribute section

The following only applies to CHARGE, HEAT, FEEM, DGTD:

If the material chosen from the drop down menu is a binary alloy consisting of two semiconductors, then there will be an additional property, namely, the "composition fraction" to set as well.

- COMPOSITION FRACTION: This is x, the fraction of the semiconductor in the alloy. x can either take a fixed value or vary.

The user can see which semiconductor has fraction x and which has fraction (1-x) shown in a line above this drop down menu.

- FIXED: This means that fraction x will be a constant value between 0 and 1.

- LINEAR X/Y/Z: This means that the composition fraction x will vary as a function x or y or z. In this case, user can specify the min and max fraction values for the min and max spatial points and the fraction will be interpolated linearly in between. x,y,z here are those of the unrotated object. x,y,z are local to the object.

- EQUATION: The user can enter an equation for the fraction that varies with u,v and w. u is (x-x0), v is (y-y0) and w is (z-z0) where x0, y0 and z0 are the center coordinates of the object. This means that u,v and w are local to the object.

Rotation tab

Rotate objects by setting the following variables:

- FIRST, SECOND, THIRD AXES: Select rotation axis. Up to three different rotations can be applied.

- ROTATION 1,2,3: The rotation of the object in a clockwise direction about each axis, measured in degrees.

Graphical Rendering tab

The graphical rendering tab is used to change how objects are drawn in the layout editor. The options are:

- RENDER TYPE: The options for drawing the objects are detailed or wireframe. Detailed objects are shaded and their transparency can be set using OVERRIDE COLOR OPACITY FROM MATERIAL DATABASE.

- DETAIL: This is a slider which takes values between 0 and 1. By default it is set to 0.5. Higher detail shows more detail, but increases the time required to draw objects. This setting has no effect on the simulation.

- OVERRIDE COLOR OPACITY FROM MATERIAL DATABASE: When unselected the opacity is determined from the material database. When selected, you can specify a value for ALPHA between 0 (transparent) and 1 (opaque) for the object, depending on how transparent you want the object to be.

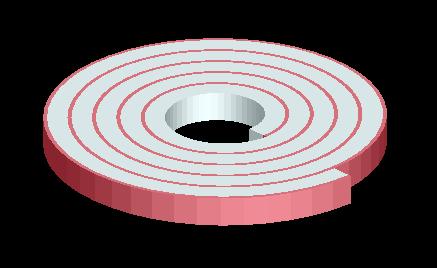

Ring - Simulation Object

FDTD MODE DGTD CHARGE HEAT FEEM

Ring regions represent physical objects that consist of full or partial rings when viewed from above. Rings in 3D simulations are extruded in the z direction to a specific height.

Geometry tab

- X, Y, Z: The center position of the object

- Z MIN, Z MAX: Z min, Z max position

- Z SPAN: Z span of the object

- OUTER RADIUS, INNER RADIUS: Outer and inner radius of the ring

- THETA START, THETA STOP: Specify the angle range that ring to be drawn, in degree.

- MAKE ELLIPSOID: if this box is checked, a second outer and inner radius can be defined

Material tab

The material options are as follows:

- MATERIAL: This field can be set to any material included in the material database. It is possible to include new materials in the database, or edit the materials already included. See the material database section for more information.

- OVERRIDE MESH ORDER FROM MATERIAL DATABASE: Select to override the mesh order from the material database and manually set a mesh order. The mesh order is used by the simulation engine to select which material to use when two materials overlap. See the mesh order (optical) or mesh order (electrical) section for more details.

- MESH ORDER: Set the mesh order in this field if the OVERRIDE MESH ORDER FROM MATERIAL DATABASE option is selected. If the option is not selected, the field displays the material's default mesh order from the database. For example, a material of mesh order 1 will take precedence over a material of mesh order 2.

The following only applies to MODE and FDTD:

If <Object defined dielectric> is selected, then the INDEX property must be set.

- INDEX: The refractive index of the structure, when the material type is <Object defined dielectric>. The index must be greater than one.

-

-

- Anisotropic index: To specify an anisotropic refractive index, use a semicolon to separate the diagonal xx,yy,zz indices. Eg. 1;1.5;1

- Spatially varying index: It is possible to specify a spatially varying refractive index by entering an equation of the variables x,y,z in this field. Eg. 2+0.1*x will create an object where the refractive index increases in the X direction. The units of the spatial variables (x,y,z) must be set with the 'INDEX UNITS' property described below. The variables x,y,z will be zero in the center of the object. When using an equation in this field, consider using a mesh override region to control the simulation mesh size. For more information on entering equations, see the Equation interpreter section.

-

- INDEX UNITS: Only relevant when specifying a spatially varying equation in the INDEX properly described above. Specify the units (nm, um, m) of the x,y,z position variables.

- GRID ATTRIBUTE NAME: Enter the name of the grid attribute that applies to this object, see the grid attribute section

The following only applies to CHARGE, HEAT, FEEM, DGTD:

If the material chosen from the drop down menu is a binary alloy consisting of two semiconductors, then there will be an additional property, namely, the "composition fraction" to set as well.

- COMPOSITION FRACTION: This is x, the fraction of the semiconductor in the alloy. x can either take a fixed value or vary.

The user can see which semiconductor has fraction x and which has fraction (1-x) shown in a line above this drop down menu.

- FIXED: This means that fraction x will be a constant value between 0 and 1.

- LINEAR X/Y/Z: This means that the composition fraction x will vary as a function x or y or z. In this case, user can specify the min and max fraction values for the min and max spatial points and the fraction will be interpolated linearly in between. x,y,z here are those of the unrotated object. x,y,z are local to the object.

- EQUATION: The user can enter an equation for the fraction that varies with u,v and w. u is (x-x0), v is (y-y0) and w is (z-z0) where x0, y0 and z0 are the center coordinates of the object. This means that u,v and w are local to the object.

Rotation tab

Rotate objects by setting the following variables:

- FIRST, SECOND, THIRD AXES: Select rotation axis. Up to three different rotations can be applied.

- ROTATION 1,2,3: The rotation of the object in a clockwise direction about each axis, measured in degrees.

Graphical Rendering tab

The graphical rendering tab is used to change how objects are drawn in the layout editor. The options are:

- RENDER TYPE: The options for drawing the objects are detailed or wireframe. Detailed objects are shaded and their transparency can be set using OVERRIDE COLOR OPACITY FROM MATERIAL DATABASE.

- DETAIL: This is a slider which takes values between 0 and 1. By default it is set to 0.5. Higher detail shows more detail, but increases the time required to draw objects. This setting has no effect on the simulation.

- OVERRIDE COLOR OPACITY FROM MATERIAL DATABASE: When unselected the opacity is determined from the material database. When selected, you can specify a value for ALPHA between 0 (transparent) and 1 (opaque) for the object, depending on how transparent you want the object to be.

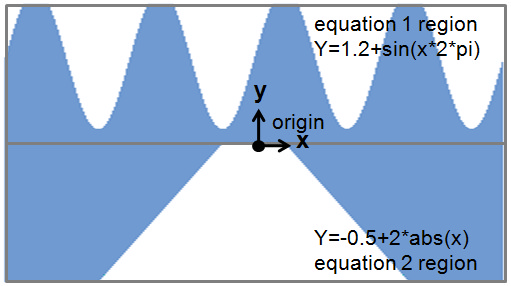

Custom structure object - Simulation Object

Custom primitives are objects that are defined by equations describing the boundaries of the physical object. The custom primitive defaults to a rectangular region upon creation, and is shaped via the entry of one or more equations in the edit window. The custom object allows you to define the y position of the object as a function of the x position. The z position is obtained via extrusion or revolution of the y edge. (X,Y)=(0,0) corresponds to the center of the object.

Geometry tab

- X, Y, Z: The center position of the object

- X MIN, X MAX: X min, X max position

- Y MIN, Y MAX: Y min, Y max position

- Z MIN, Z MAX: Z min, Z max position

- X SPAN, Y SPAN, Z SPAN: X, Y, Z span of the object

Custom tab

- EQUATION 1: Defines the equation in the upper region (y>0

- )

- MAKE NONSYMMETRIC: Enabled only when creating the object by extrusion

-

- EQUATION 2: Defines the equation in the lower region (y<0

-

-

-

- )

-

- EQUATION UNITS: The units used in the equation. (Default: microns)

- CREATE 3D OBJECT BY: Choose whether to define the 3D object by revolution or extrusion.

Material tab

The material options are as follows:

- MATERIAL: This field can be set to any material included in the material database. It is possible to include new materials in the database, or edit the materials already included. See the material database section for more information.

- OVERRIDE MESH ORDER FROM MATERIAL DATABASE: Select to override the mesh order from the material database and manually set a mesh order. The mesh order is used by the simulation engine to select which material to use when two materials overlap. See the mesh order (optical) or mesh order (electrical) section for more details.

- MESH ORDER: Set the mesh order in this field if the OVERRIDE MESH ORDER FROM MATERIAL DATABASE option is selected. If the option is not selected, the field displays the material's default mesh order from the database. For example, a material of mesh order 1 will take precedence over a material of mesh order 2.

The following only applies to MODE and FDTD:

If <Object defined dielectric> is selected, then the INDEX property must be set.

- INDEX: The refractive index of the structure, when the material type is <Object defined dielectric>. The index must be greater than one.

- Anisotropic index: To specify an anisotropic refractive index, use a semicolon to separate the diagonal xx,yy,zz indices. Eg. 1;1.5;1

- Spatially varying index: It is possible to specify a spatially varying refractive index by entering an equation of the variables x,y,z in this field. Eg. 2+0.1*x will create an object where the refractive index increases in the X direction. The units of the spatial variables (x,y,z) must be set with the 'INDEX UNITS' property described below. The variables x,y,z will be zero in the center of the object. When using an equation in this field, consider using a mesh override region to control the simulation mesh size. For more information on entering equations, see the Equation interpreter section.

- INDEX UNITS: Only relevant when specifying a spatially varying equation in the INDEX properly described above. Specify the units (nm, um, m) of the x,y,z position variables.

- GRID ATTRIBUTE NAME: Enter the name of the grid attribute that applies to this object, see the grid attribute section

The following only applies to CHARGE, HEAT, FEEM, DGTD:

If the material chosen from the drop down menu is a binary alloy consisting of two semiconductors, then there will be an additional property, namely, the "composition fraction" to set as well.

- COMPOSITION FRACTION: This is x, the fraction of the semiconductor in the alloy. x can either take a fixed value or vary.

The user can see which semiconductor has fraction x and which has fraction (1-x) shown in a line above this drop down menu.

- FIXED: This means that fraction x will be a constant value between 0 and 1.

- LINEAR X/Y/Z: This means that the composition fraction x will vary as a function x or y or z. In this case, user can specify the min and max fraction values for the min and max spatial points and the fraction will be interpolated linearly in between. x,y,z here are those of the unrotated object. x,y,z are local to the object.

- EQUATION: The user can enter an equation for the fraction that varies with u,v and w. u is (x-x0), v is (y-y0) and w is (z-z0) where x0, y0 and z0 are the center coordinates of the object. This means that u,v and w are local to the object.

Rotation tab

Rotate objects by setting the following variables:

- FIRST, SECOND, THIRD AXES: Select rotation axis. Up to three different rotations can be applied.

- ROTATION 1,2,3: The rotation of the object in a clockwise direction about each axis, measured in degrees.

Graphical Rendering tab

The graphical rendering tab is used to change how objects are drawn in the layout editor. The options are:

- RENDER TYPE: The options for drawing the objects are detailed or wireframe. Detailed objects are shaded and their transparency can be set using OVERRIDE COLOR OPACITY FROM MATERIAL DATABASE.

- DETAIL: This is a slider which takes values between 0 and 1. By default it is set to 0.5. Higher detail shows more detail, but increases the time required to draw objects. This setting has no effect on the simulation.

- OVERRIDE COLOR OPACITY FROM MATERIAL DATABASE: When unselected the opacity is determined from the material database. When selected, you can specify a value for ALPHA between 0 (transparent) and 1 (opaque) for the object, depending on how transparent you want the object to be.

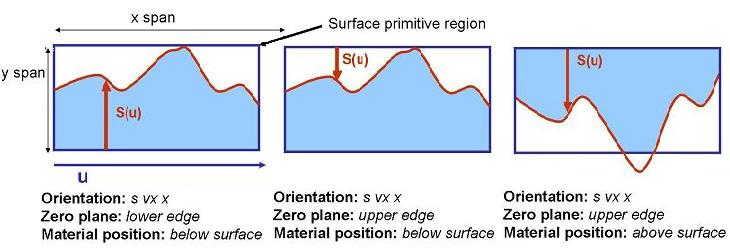

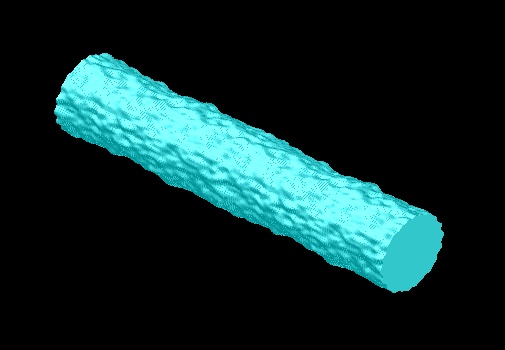

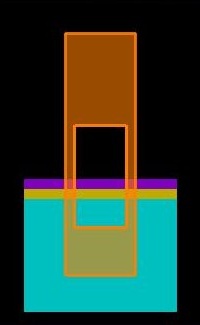

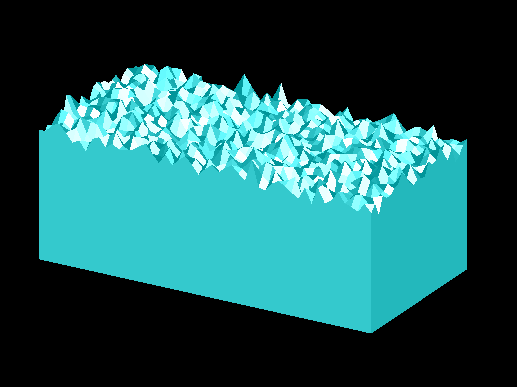

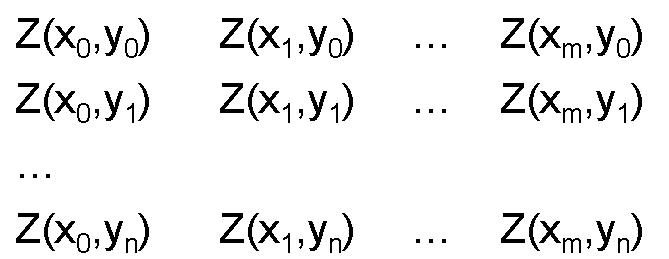

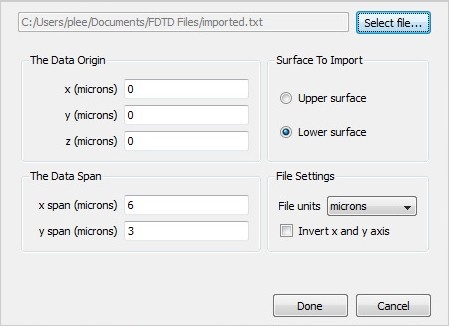

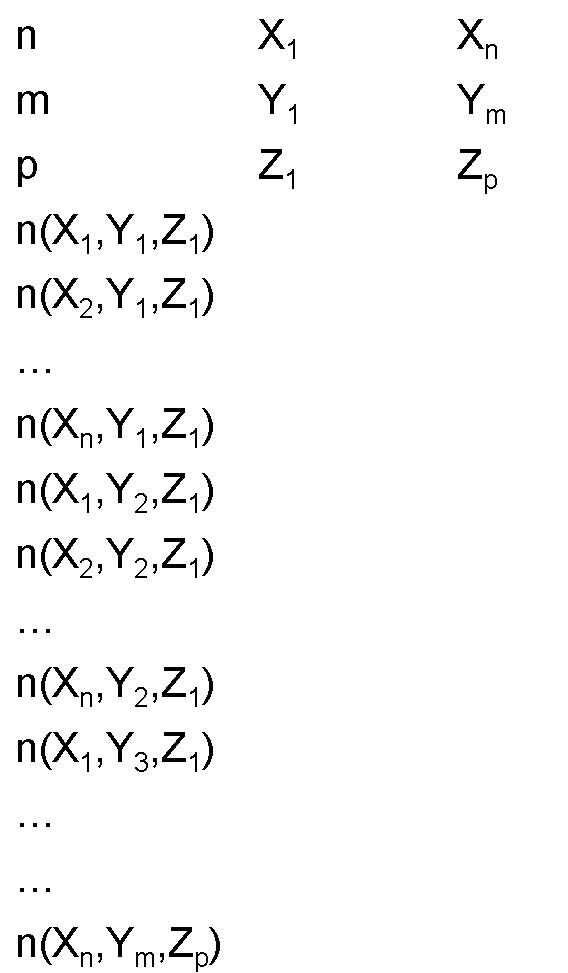

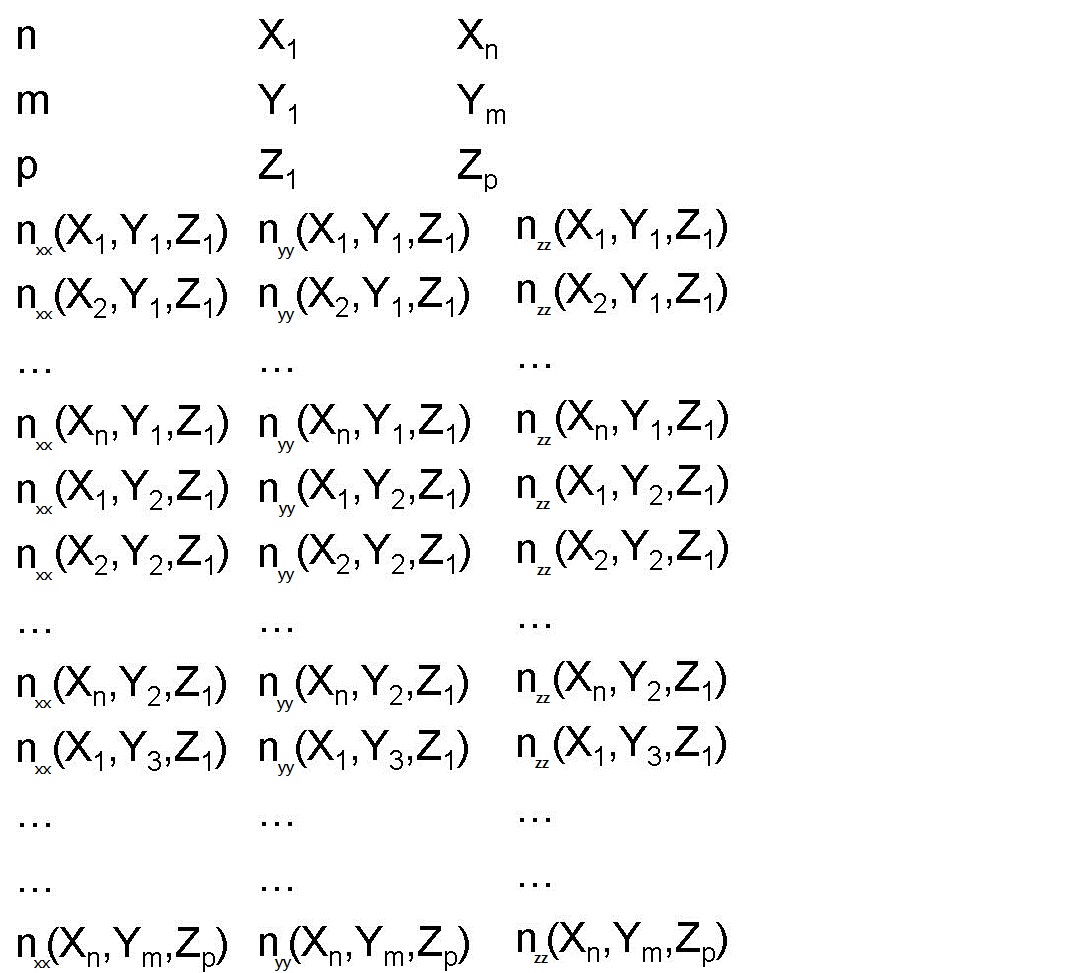

Surface structure object - Simulation Object

This page provides a simulation file containing several example structures created with the surface object, to demonstrate the types of structures that can be created with this object. Surface primitives can be used to define complex material volumes that exist above or below analytically defined surfaces. In 3D simulations, a surface (S) is defined as a function of variables u and v, i.e. S = S(u,v). The variables (u,v) can represent (x,y), (x,z) or (y,z) depending on the surface orientation. Similarly, in 2D simulations, a surface is defined as a function of u (S = S(u)) where u can represent x or y.

The simulation file usr_surface_example.fsp contains several examples of surface objects that can be created using conic, polynomial, and custom equation options. More examples of the surface objects can be found in the object library available in FDTD.

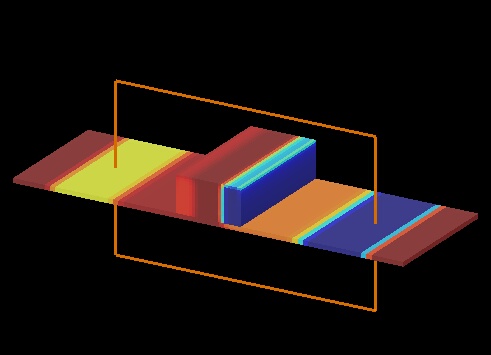

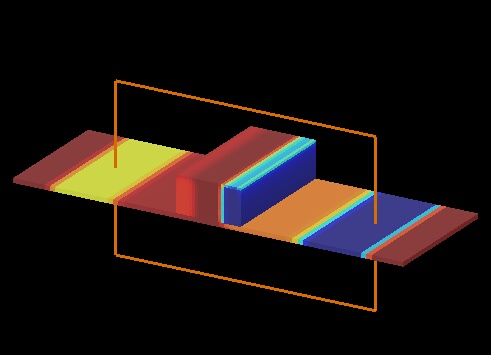

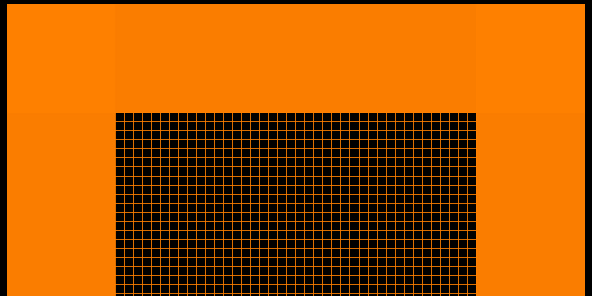

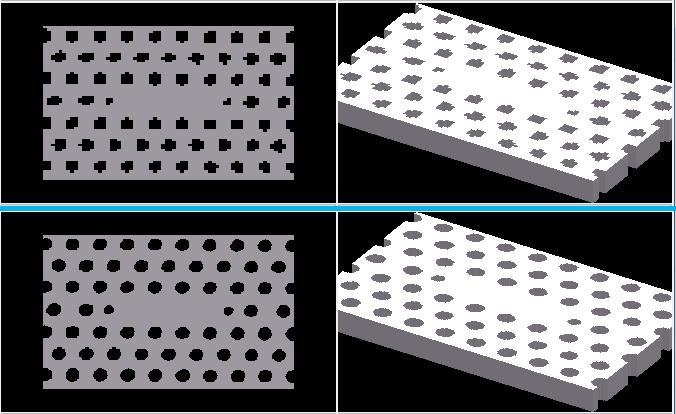

| Note: Drawing resolution Initially the object will be drawn at a low resolution, as shown in the top half of this figure. You can increase the drawing resolution with the settings on the Graphical rendering tab. The bottom half of this figure shows the object displayed at the same resolution as the image that is was imported from. It is important to note that the graphical rendering does not affect the simulation. Irrespective of the drawing resolution, the meshed object used for the simulation is always as has been defined. |

The custom tab is only available for surface primitives in MODE and FDTD. The diagrams below show how the surface is used to create a volume of desired material.

The surface equation can contain up to three terms, conic, polynomial and custom which are added together to create the total surface. Not all terms have to be included.

S=Sconic+Spolynomial+Scustom

Conic term:

Sconic=cr21+√1−(κ+1)c2r2

c = 1/R, c is the inverse of the radius of curvature of the surface at r = 0.

- κ

is the conic constant. When κ=−1 we have a parabolic surface. When κ=0

- we have a spherical surface.

- r2 = u2 + v2.

Polynomial term:

Spolynomial=∑5i,j=0Mijuivj

- There are 36 available coefficients

Custom term:

Scustom=f(u,v)

- You can choose any analytic function of (u,v).

- The syntax and functions available to specify the index are found in the Equation interpreter section.

For example, you could use

Scustom=sin(u+v)

Geometry tab

- X, Y, Z: The center position of the object

- X MIN, X MAX: X min, X max position

- Y MIN, Y MAX: Y min, Y max position

- Z MIN, Z MAX: Z min, Z max position

- X SPAN, Y SPAN, Z SPAN: X, Y, Z span of the object

Surface tab

- ORIENTATION: The surface determines if S is a function of (x,y), (x,z) or (y,z)..

- ZERO PLANE: This determines if surface is measured from the lower edge of the rectangular volume or the upper edge. See diagrams above.

- MATERIAL POSITION: This determines if the material fills the regions above the surface or below the surface. See diagrams above.

- SET UNDEFINED TERMS TO: It is possible that the surface equation becomes undefined. For example, it could be sqrt(-1) for some values of (u,v). In this case, the surface function will become either zero or the maximum value allowed by the rectangular volume encompassing the surface object.

- U0, V0: The origin of the (u,v) coordinate system, If U0, V0 are zero, then (u,v) = (0,0) will correspond to the center of the surface object. Setting these values to non-zero will offset the origin by a desired amount.

- SURFACE UNITS: All quantities defining the surface must be measured in the same units. You can choose these units with this menu.

- CONIC: Check this option to include the conic term in the surface equation. If this is checked, then set

- RADIUS OF CURVATURE: curvature of the surface at the origin. This is equal to the inverse of the parameter c described in the definition of Sconic.

- CONIC CONSTANT: The k constant.

- CUSTOM: Check this option to include the custom term in the surface equation

- EQUATION: The equation as a function u and v.

- POLYNOMIAL: Check this option to include a polynomial term in the surface equation. If this option is checked, the M coefficients as explained above can be entered into a table.

To import a surface object, please see Import object surfaces

Material tab

The material options are as follows:

- MATERIAL: This field can be set to any material included in the material database. It is possible to include new materials in the database, or edit the materials already included. See the material database section for more information.

- OVERRIDE MESH ORDER FROM MATERIAL DATABASE: Select to override the mesh order from the material database and manually set a mesh order. The mesh order is used by the simulation engine to select which material to use when two materials overlap. See the mesh order (optical) or mesh order (electrical) section for more details.

- MESH ORDER: Set the mesh order in this field if the OVERRIDE MESH ORDER FROM MATERIAL DATABASE option is selected. If the option is not selected, the field displays the material's default mesh order from the database. For example, a material of mesh order 1 will take precedence over a material of mesh order 2.

The following only applies to MODE and FDTD:

If <Object defined dielectric> is selected, then the INDEX property must be set.

- INDEX: The refractive index of the structure, when the material type is <Object defined dielectric>. The index must be greater than one.

- Anisotropic index: To specify an anisotropic refractive index, use a semicolon to separate the diagonal xx,yy,zz indices. Eg. 1;1.5;1

- Spatially varying index: It is possible to specify a spatially varying refractive index by entering an equation of the variables x,y,z in this field. Eg. 2+0.1*x will create an object where the refractive index increases in the X direction. The units of the spatial variables (x,y,z) must be set with the 'INDEX UNITS' property described below. The variables x,y,z will be zero in the center of the object. When using an equation in this field, consider using a mesh override region to control the simulation mesh size. For more information on entering equations, see the Equation interpreter section.

- INDEX UNITS: Only relevant when specifying a spatially varying equation in the INDEX properly described above. Specify the units (nm, um, m) of the x,y,z position variables.

- GRID ATTRIBUTE NAME: Enter the name of the grid attribute that applies to this object, see the grid attribute section

The following only applies to CHARGE, HEAT, FEEM, DGTD:

If the material chosen from the drop down menu is a binary alloy consisting of two semiconductors, then there will be an additional property, namely, the "composition fraction" to set as well.

- COMPOSITION FRACTION: This is x, the fraction of the semiconductor in the alloy. x can either take a fixed value or vary.

The user can see which semiconductor has fraction x and which has fraction (1-x) shown in a line above this drop down menu.

- FIXED: This means that fraction x will be a constant value between 0 and 1.

- LINEAR X/Y/Z: This means that the composition fraction x will vary as a function x or y or z. In this case, user can specify the min and max fraction values for the min and max spatial points and the fraction will be interpolated linearly in between. x,y,z here are those of the unrotated object. x,y,z are local to the object.

- EQUATION: The user can enter an equation for the fraction that varies with u,v and w. u is (x-x0), v is (y-y0) and w is (z-z0) where x0, y0 and z0 are the center coordinates of the object. This means that u,v and w are local to the object.

Rotation tab

Rotate objects by setting the following variables:

- FIRST, SECOND, THIRD AXES: Select rotation axis. Up to three different rotations can be applied.

- ROTATION 1,2,3: The rotation of the object in a clockwise direction about each axis, measured in degrees.

Graphical Rendering tab

The graphical rendering tab is used to change how objects are drawn in the layout editor. The options are:

- RENDER TYPE: The options for drawing the objects are detailed or wireframe. Detailed objects are shaded and their transparency can be set using OVERRIDE COLOR OPACITY FROM MATERIAL DATABASE.

- DETAIL: This is a slider which takes values between 0 and 1. By default it is set to 0.5. Higher detail shows more detail, but increases the time required to draw objects. This setting has no effect on the simulation.

- OVERRIDE COLOR OPACITY FROM MATERIAL DATABASE: When unselected the opacity is determined from the material database. When selected, you can specify a value for ALPHA between 0 (transparent) and 1 (opaque) for the object, depending on how transparent you want the object to be.

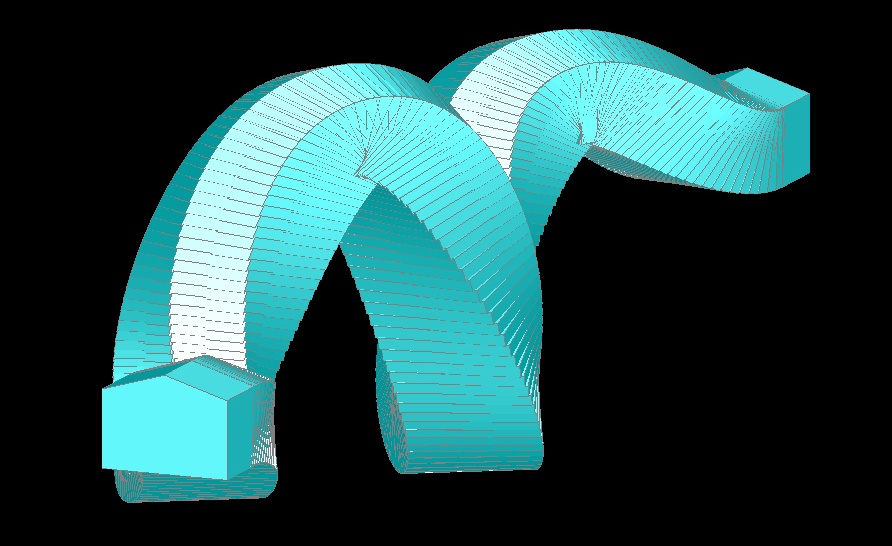

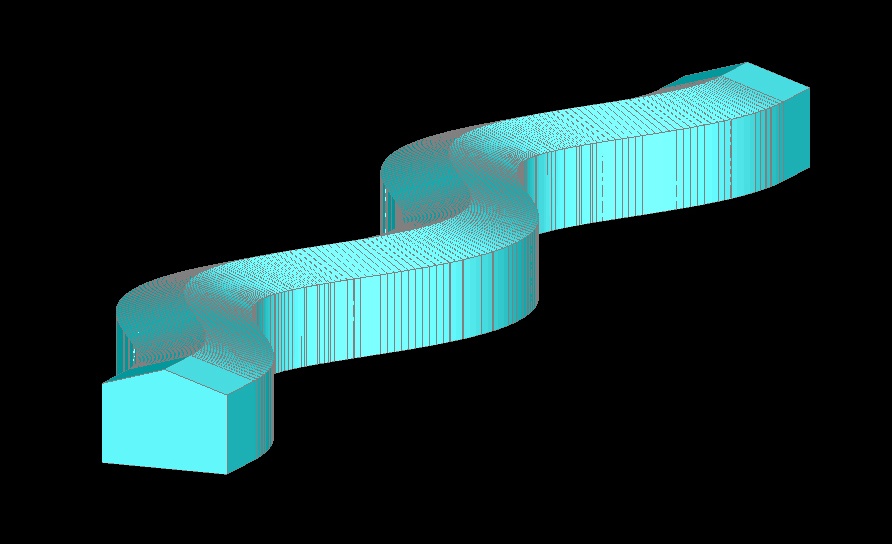

Waveguide - Simulation Object

FDTD MODE DGTD CHARGE HEAT FEEM

This section describes how to create a waveguide having an isosceles trapezoidal cross section and a Bézier-curved path.

Bézier curves are widely used in computer graphics for the generation of smooth curves. The path of the curve, B(t), are defined by a set of control points, called poles, P0, P1, ...., Pn and its mathematical representation is as follows:

where

![]()

is the binomial coefficients.

For n=1, the curve reduces to a straight line defined by the interpolation of the points P0 and P1.

For n=3, the curves are called cubic Bézier curves, which, together with quadratic (n=2) ones, are most commonly used . Some of the cubic Bezier curve examples are shown below.

Geometry tab

- X, Y, Z: The center position of the object

- Base width, Base height, Base Angle: The width, height, sidewall angle of the waveguide cross section

- Poles: Positions of Bezier poles.

Material tab

The material options are as follows:

- MATERIAL: This field can be set to any material included in the material database. It is possible to include new materials in the database, or edit the materials already included. See the material database section for more information.

- OVERRIDE MESH ORDER FROM MATERIAL DATABASE: Select to override the mesh order from the material database and manually set a mesh order. The mesh order is used by the simulation engine to select which material to use when two materials overlap. See the mesh order (optical) or mesh order (electrical) section for more details.

- MESH ORDER: Set the mesh order in this field if the OVERRIDE MESH ORDER FROM MATERIAL DATABASE option is selected. If the option is not selected, the field displays the material's default mesh order from the database. For example, a material of mesh order 1 will take precedence over a material of mesh order 2.

The following only applies to MODE and FDTD:

If <Object defined dielectric> is selected, then the INDEX property must be set.

- INDEX: The refractive index of the structure, when the material type is <Object defined dielectric>. The index must be greater than one.

-

-

- Anisotropic index: To specify an anisotropic refractive index, use a semicolon to separate the diagonal xx,yy,zz indices. Eg. 1;1.5;1

- Spatially varying index: It is possible to specify a spatially varying refractive index by entering an equation of the variables x,y,z in this field. Eg. 2+0.1*x will create an object where the refractive index increases in the X direction. The units of the spatial variables (x,y,z) must be set with the 'INDEX UNITS' property described below. The variables x,y,z will be zero in the center of the object. When using an equation in this field, consider using a mesh override region to control the simulation mesh size. For more information on entering equations, see the Equation interpreter section.

-

- INDEX UNITS: Only relevant when specifying a spatially varying equation in the INDEX properly described above. Specify the units (nm, um, m) of the x,y,z position variables.

- GRID ATTRIBUTE NAME: Enter the name of the grid attribute that applies to this object, see the grid attribute section

The following only applies to CHARGE, HEAT, FEEM, DGTD:

If the material chosen from the drop down menu is a binary alloy consisting of two semiconductors, then there will be an additional property, namely, the "composition fraction" to set as well.

- COMPOSITION FRACTION: This is x, the fraction of the semiconductor in the alloy. x can either take a fixed value or vary.

The user can see which semiconductor has fraction x and which has fraction (1-x) shown in a line above this drop down menu.

- FIXED: This means that fraction x will be a constant value between 0 and 1.

- LINEAR X/Y/Z: This means that the composition fraction x will vary as a function x or y or z. In this case, user can specify the min and max fraction values for the min and max spatial points and the fraction will be interpolated linearly in between. x,y,z here are those of the unrotated object. x,y,z are local to the object.

- EQUATION: The user can enter an equation for the fraction that varies with u,v and w. u is (x-x0), v is (y-y0) and w is (z-z0) where x0, y0 and z0 are the center coordinates of the object. This means that u,v and w are local to the object.

Rotation tab

Rotate objects by setting the following variables:

- FIRST, SECOND, THIRD AXES: Select rotation axis. Up to three different rotations can be applied.

- ROTATION 1,2,3: The rotation of the object in a clockwise direction about each axis, measured in degrees.

Graphical Rendering tab

The graphical rendering tab is used to change how objects are drawn in the layout editor. The options are:

- RENDER TYPE: The options for drawing the objects are detailed or wireframe. Detailed objects are shaded and their transparency can be set using OVERRIDE COLOR OPACITY FROM MATERIAL DATABASE.

- DETAIL: This is a slider which takes values between 0 and 1. By default it is set to 0.5. Higher detail shows more detail, but increases the time required to draw objects. This setting has no effect on the simulation.

- OVERRIDE COLOR OPACITY FROM MATERIAL DATABASE: When unselected the opacity is determined from the material database. When selected, you can specify a value for ALPHA between 0 (transparent) and 1 (opaque) for the object, depending on how transparent you want the object to be.

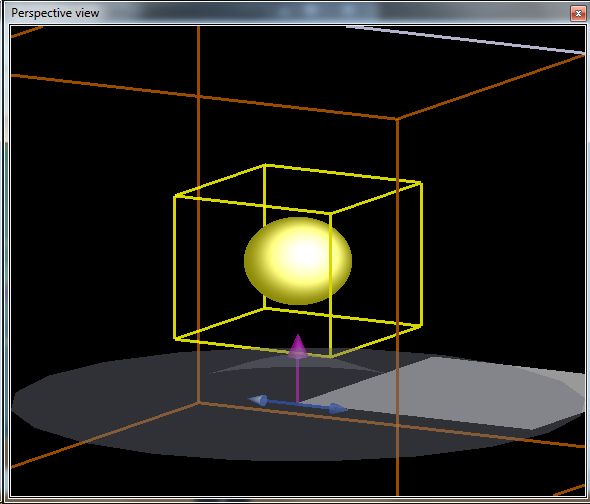

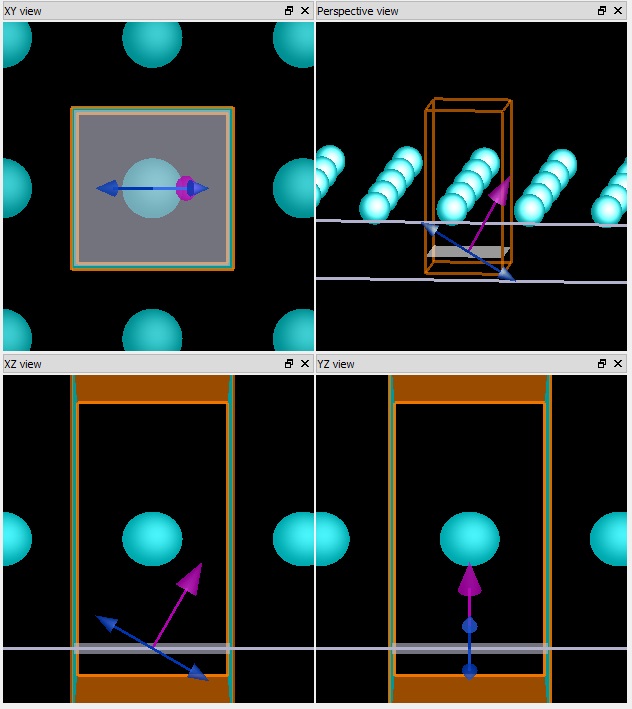

Sphere - Simulation Object

FDTD MODE DGTD CHARGE HEAT FEEM

This page describes a sphere object.

Geometry tab

- X, Y, Z: The center position of the object

- RADIUS: Radius of the object

- MAKE ELLIPSOID: If this box is checked, second and third radii can be defined

Material tab

The material options are as follows:

- MATERIAL: This field can be set to any material included in the material database. It is possible to include new materials in the database, or edit the materials already included. See the material database section for more information.

- OVERRIDE MESH ORDER FROM MATERIAL DATABASE: Select to override the mesh order from the material database and manually set a mesh order. The mesh order is used by the simulation engine to select which material to use when two materials overlap. See the mesh order (optical) or mesh order (electrical) section for more details.

- MESH ORDER: Set the mesh order in this field if the OVERRIDE MESH ORDER FROM MATERIAL DATABASE option is selected. If the option is not selected, the field displays the material's default mesh order from the database. For example, a material of mesh order 1 will take precedence over a material of mesh order 2.

The following only applies to MODE and FDTD:

If <Object defined dielectric> is selected, then the INDEX property must be set.

- INDEX: The refractive index of the structure, when the material type is <Object defined dielectric>. The index must be greater than one.

-

-

- Anisotropic index: To specify an anisotropic refractive index, use a semicolon to separate the diagonal xx,yy,zz indices. Eg. 1;1.5;1

- Spatially varying index: It is possible to specify a spatially varying refractive index by entering an equation of the variables x,y,z in this field. Eg. 2+0.1*x will create an object where the refractive index increases in the X direction. The units of the spatial variables (x,y,z) must be set with the 'INDEX UNITS' property described below. The variables x,y,z will be zero in the center of the object. When using an equation in this field, consider using a mesh override region to control the simulation mesh size. For more information on entering equations, see the Equation interpreter section.

-

- INDEX UNITS: Only relevant when specifying a spatially varying equation in the INDEX properly described above. Specify the units (nm, um, m) of the x,y,z position variables.

- GRID ATTRIBUTE NAME: Enter the name of the grid attribute that applies to this object, see the grid attribute section

The following only applies to CHARGE, HEAT, FEEM, DGTD:

If the material chosen from the drop down menu is a binary alloy consisting of two semiconductors, then there will be an additional property, namely, the "composition fraction" to set as well.

- COMPOSITION FRACTION: This is x, the fraction of the semiconductor in the alloy. x can either take a fixed value or vary.

The user can see which semiconductor has fraction x and which has fraction (1-x) shown in a line above this drop down menu.

- FIXED: This means that fraction x will be a constant value between 0 and 1.

- LINEAR X/Y/Z: This means that the composition fraction x will vary as a function x or y or z. In this case, user can specify the min and max fraction values for the min and max spatial points and the fraction will be interpolated linearly in between. x,y,z here are those of the unrotated object. x,y,z are local to the object.

- EQUATION: The user can enter an equation for the fraction that varies with u,v and w. u is (x-x0), v is (y-y0) and w is (z-z0) where x0, y0 and z0 are the center coordinates of the object. This means that u,v and w are local to the object.

Rotation tab

Rotate objects by setting the following variables:

- FIRST, SECOND, THIRD AXES: Select rotation axis. Up to three different rotations can be applied.

- ROTATION 1,2,3: The rotation of the object in a clockwise direction about each axis, measured in degrees.

Graphical Rendering tab

The graphical rendering tab is used to change how objects are drawn in the layout editor. The options are:

- RENDER TYPE: The options for drawing the objects are detailed or wireframe. Detailed objects are shaded and their transparency can be set using OVERRIDE COLOR OPACITY FROM MATERIAL DATABASE.

- DETAIL: This is a slider which takes values between 0 and 1. By default it is set to 0.5. Higher detail shows more detail, but increases the time required to draw objects. This setting has no effect on the simulation.

- OVERRIDE COLOR OPACITY FROM MATERIAL DATABASE: When unselected the opacity is determined from the material database. When selected, you can specify a value for ALPHA between 0 (transparent) and 1 (opaque) for the object, depending on how transparent you want the object to be.

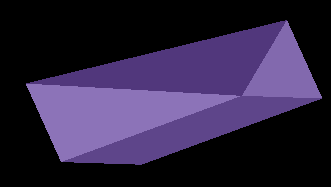

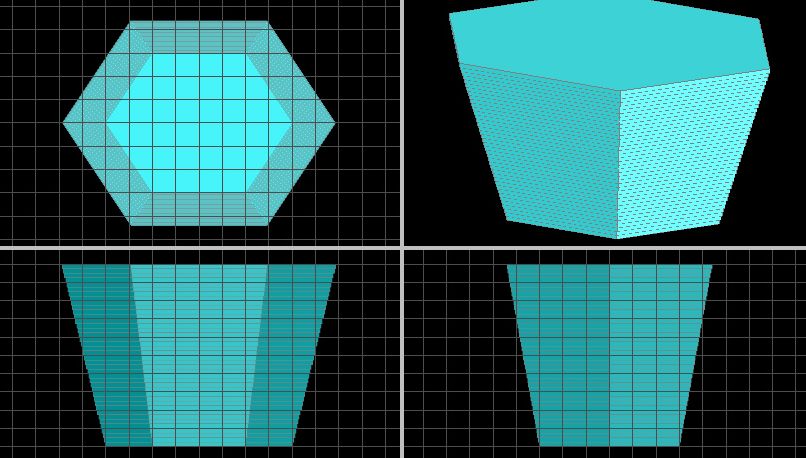

Pyramid - Simulation Object

FDTD MODE DGTD CHARGE HEAT FEEM

This page describes a pyramid object. Pyramids can be configured to half flat tops and/or flat bottoms, and either narrow or expand in the vertical z direction.

Geometry tab

- X, Y, Z: The center position of the object

- X SPAN BOTTOM, X SPAN TOP: X bottom, top span of the object

- Y SPAN BOTTOM, Y SPAN TOP: Y bottom, top span of the object

- Z MIN, Z MAX: Z min, Z max position

- Z SPAN: Z span of the object

Material tab

The material options are as follows:

- MATERIAL: This field can be set to any material included in the material database. It is possible to include new materials in the database, or edit the materials already included. See the material database section for more information.

- OVERRIDE MESH ORDER FROM MATERIAL DATABASE: Select to override the mesh order from the material database and manually set a mesh order. The mesh order is used by the simulation engine to select which material to use when two materials overlap. See the mesh order (optical) or mesh order (electrical) section for more details.

- MESH ORDER: Set the mesh order in this field if the OVERRIDE MESH ORDER FROM MATERIAL DATABASE option is selected. If the option is not selected, the field displays the material's default mesh order from the database. For example, a material of mesh order 1 will take precedence over a material of mesh order 2.

The following only applies to MODE and FDTD:

If <Object defined dielectric> is selected, then the INDEX property must be set.

- INDEX: The refractive index of the structure, when the material type is <Object defined dielectric>. The index must be greater than one.

-

-

- Anisotropic index: To specify an anisotropic refractive index, use a semicolon to separate the diagonal xx,yy,zz indices. Eg. 1;1.5;1

- Spatially varying index: It is possible to specify a spatially varying refractive index by entering an equation of the variables x,y,z in this field. Eg. 2+0.1*x will create an object where the refractive index increases in the X direction. The units of the spatial variables (x,y,z) must be set with the 'INDEX UNITS' property described below. The variables x,y,z will be zero in the center of the object. When using an equation in this field, consider using a mesh override region to control the simulation mesh size. For more information on entering equations, see the Equation interpreter section.

-

- INDEX UNITS: Only relevant when specifying a spatially varying equation in the INDEX properly described above. Specify the units (nm, um, m) of the x,y,z position variables.

- GRID ATTRIBUTE NAME: Enter the name of the grid attribute that applies to this object, see the grid attribute section

The following only applies to CHARGE, HEAT, FEEM, DGTD:

If the material chosen from the drop down menu is a binary alloy consisting of two semiconductors, then there will be an additional property, namely, the "composition fraction" to set as well.

- COMPOSITION FRACTION: This is x, the fraction of the semiconductor in the alloy. x can either take a fixed value or vary.

The user can see which semiconductor has fraction x and which has fraction (1-x) shown in a line above this drop down menu.

- FIXED: This means that fraction x will be a constant value between 0 and 1.

- LINEAR X/Y/Z: This means that the composition fraction x will vary as a function x or y or z. In this case, user can specify the min and max fraction values for the min and max spatial points and the fraction will be interpolated linearly in between. x,y,z here are those of the unrotated object. x,y,z are local to the object.

- EQUATION: The user can enter an equation for the fraction that varies with u,v and w. u is (x-x0), v is (y-y0) and w is (z-z0) where x0, y0 and z0 are the center coordinates of the object. This means that u,v and w are local to the object.

Rotation tab

Rotate objects by setting the following variables:

- FIRST, SECOND, THIRD AXES: Select rotation axis. Up to three different rotations can be applied.

- ROTATION 1,2,3: The rotation of the object in a clockwise direction about each axis, measured in degrees.

Graphical Rendering tab

The graphical rendering tab is used to change how objects are drawn in the layout editor. The options are:

- RENDER TYPE: The options for drawing the objects are detailed or wireframe. Detailed objects are shaded and their transparency can be set using OVERRIDE COLOR OPACITY FROM MATERIAL DATABASE.

- DETAIL: This is a slider which takes values between 0 and 1. By default it is set to 0.5. Higher detail shows more detail, but increases the time required to draw objects. This setting has no effect on the simulation.

- OVERRIDE COLOR OPACITY FROM MATERIAL DATABASE: When unselected the opacity is determined from the material database. When selected, you can specify a value for ALPHA between 0 (transparent) and 1 (opaque) for the object, depending on how transparent you want the object to be.

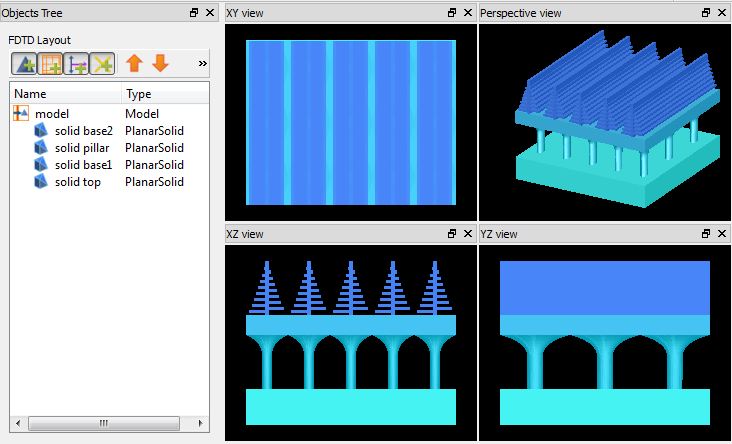

Planar solid - Simulation Object

FDTD MODE DGTD CHARGE HEAT FEEM

The planar solid object behaves somewhat like the polygon structure, but generalized to 3D. The object vertices cannot be set via the GUI; a script command must be used. The image below shows how a facet is defined to denote positive or negative spaces. In the shape below one facet comprises of two paths : p1=[1,3,2,5,4] , p2=[16,17,18,19].

Setting the vertices of the polygon object

The vertices of the planar solid object can be edited using scripting by two methods:

- Specifying the vertices as a cell array.

- Specifying the vertices as a matrix.

For complex shapes, one can use multiple primitives and set the mesh orders of overlapping structures to achieve the desired shape, but using the planar solid primitive allows you to use just one object to implement complex shapes.

Geometry tab

- X, Y, Z: The center position of the object

Material tab

The material options are as follows:

MATERIAL: This field can be set to any material included in the material database. It is possible to include new materials in the database, or edit the materials already included. See the material database section for more information.

- OVERRIDE MESH ORDER FROM MATERIAL DATABASE: Select to override the mesh order from the material database and manually set a mesh order. The mesh order is used by the simulation engine to select which material to use when two materials overlap. See the mesh order (optical) or mesh order (electrical) section for more details.

- MESH ORDER: Set the mesh order in this field if the OVERRIDE MESH ORDER FROM MATERIAL DATABASE option is selected. If the option is not selected, the field displays the material's default mesh order from the database. For example, a material of mesh order 1 will take precedence over a material of mesh order 2.

The following only applies to MODE and FDTD:

If <Object defined dielectric> is selected, then the INDEX property must be set.

- INDEX: The refractive index of the structure, when the material type is <Object defined dielectric>. The index must be greater than one.

-

-

- Anisotropic index: To specify an anisotropic refractive index, use a semicolon to separate the diagonal xx,yy,zz indices. Eg. 1;1.5;1

- Spatially varying index: It is possible to specify a spatially varying refractive index by entering an equation of the variables x,y,z in this field. Eg. 2+0.1*x will create an object where the refractive index increases in the X direction. The units of the spatial variables (x,y,z) must be set with the 'INDEX UNITS' property described below. The variables x,y,z will be zero in the center of the object. When using an equation in this field, consider using a mesh override region to control the simulation mesh size. For more information on entering equations, see the Equation interpreter section.

-

- INDEX UNITS: Only relevant when specifying a spatially varying equation in the INDEX properly described above. Specify the units (nm, um, m) of the x,y,z position variables.

- GRID ATTRIBUTE NAME: Enter the name of the grid attribute that applies to this object, see the grid attribute section

The following only applies to CHARGE, HEAT, FEEM, DGTD:

If the material chosen from the drop down menu is a binary alloy consisting of two semiconductors, then there will be an additional property, namely, the "composition fraction" to set as well.

- COMPOSITION FRACTION: This is x, the fraction of the semiconductor in the alloy. x can either take a fixed value or vary.

The user can see which semiconductor has fraction x and which has fraction (1-x) shown in a line above this drop down menu.

- FIXED: This means that fraction x will be a constant value between 0 and 1.

- LINEAR X/Y/Z: This means that the composition fraction x will vary as a function x or y or z. In this case, user can specify the min and max fraction values for the min and max spatial points and the fraction will be interpolated linearly in between. x,y,z here are those of the unrotated object. x,y,z are local to the object.

- EQUATION: The user can enter an equation for the fraction that varies with u,v and w. u is (x-x0), v is (y-y0) and w is (z-z0) where x0, y0 and z0 are the center coordinates of the object. This means that u,v and w are local to the object.

Rotation tab

Rotate objects by setting the following variables:

- FIRST, SECOND, THIRD AXES: Select rotation axis. Up to three different rotations can be applied.

- ROTATION 1,2,3: The rotation of the object in a clockwise direction about each axis, measured in degrees.

Graphical Rendering tab

The graphical rendering tab is used to change how objects are drawn in the layout editor. The options are:

- RENDER TYPE: The options for drawing the objects are detailed or wireframe. Detailed objects are shaded and their transparency can be set using OVERRIDE COLOR OPACITY FROM MATERIAL DATABASE.

- DETAIL: This is a slider which takes values between 0 and 1. By default it is set to 0.5. Higher detail shows more detail, but increases the time required to draw objects. This setting has no effect on the simulation.

- OVERRIDE COLOR OPACITY FROM MATERIAL DATABASE: When unselected the opacity is determined from the material database. When selected, you can specify a value for ALPHA between 0 (transparent) and 1 (opaque) for the object, depending on how transparent you want the object to be.

Scripting example

Here we show an example script for constructing a cube with two planar holes using the planar solid primitive.

# Select method of formatting data used to create the object

method_type = 1;

# Specify vertex locations (Refer to the figure above)

vtx = [0,0,0;

1,0,0;

1,1,0;

0,1,0;

0,0,1;

1,0,1;

1,1,1;

0,1,1;

0.25,.25,0;

0.8,.25,0;

0.25,.8,0;

0.25,.25,1;

0.8,.25,1;

0.25,.8,1;

0.5,.8,0;

0.8,.5,0;

0.8,.8,0;

0.5,.8,1;

0.8,.5,1;

0.8,.8,1]*1e-6;

# Data format method 1: facet table as cell array

a = cell(12);

for (i = 1:12) {

if ((i == 1) | (i == 6)) {

a{i} = cell(3);

} else {

a{i} = cell(1);

}

}

a{1}{1} = [1,4,3,2]; # bottom facet has two holes

a{1}{2} = [9,10,11]; # first hole (orientation auto-corrected)

a{1}{3} = [15,16,17]; # second hole

a{2}{1} = [1,5,8,4]; # x min

a{3}{1} = [1,2,6,5]; # y min

a{4}{1} = [2,6,7,3]; # x max

a{5}{1} = [3,4,8,7]; # y max

a{6}{1} = [5,6,7,8]; # top face has two matching holes to bottom

a{6}{2} = [14,13,12];

a{6}{3} = [20,19,18];

a{7}{1} = [10,9,12,13]; # inner faces of holes

a{8}{1} = [11,10,13,14];

a{9}{1} = [9,11,14,12];

a{10}{1} = [16,15,18,19];

a{11}{1} = [15,17,20,18];

a{12}{1} = [17,16,19,20];

if (method_type == 1) {

addplanarsolid(vtx,a);

}

# Data format method : facet table as matrix

else {

b = matrix(4,3,12); # max four points per polygon, max 3 polygon per facet

for (i = 1:12) {

for (ipol = 1:length(a{i})) {

fpoly = a{i}{ipol};

for (j = 1:length(fpoly)) {

b(j,ipol,i) = fpoly(j);

}

}

}

addplanarsolid;

set('vertices',vtx); # must be done first

set('facets',b);

}

2D Rectangle - Simulation Object

FDTD MODE DGTD CHARGE HEAT FEEM

This is a true 2D rectangle (or a surface object), which has no thickness in the normal direction. This object can be used with the graphene model using the surface conductivity approach.

Geometry tab

- Surface normal: X, Y or Z. This is the surface normal of the 2D rectangle. When a direction of the normal is selected, the 2D rectangle object will be rotated accordingly and the corresponding direction options to specify span and min/max values will be grayed out. The 2D rectangle object has no thickness.

- X, Y, Z: The center position of the object

- X MIN, X MAX: X min, X max position

- Y MIN, Y MAX: Y min, Y max position

- Z MIN, Z MAX: Z min, Z max position

- X SPAN, Y SPAN, Z SPAN: X, Y, Z span of the object

Material tab

The material options are as follows:

- MATERIAL: The material assigned to a 2D rectangle is filtered. It can only be a dielectric with fixed index or a graphene material type.

- OVERRIDE MESH ORDER FROM MATERIAL DATABASE: Select to override the mesh order from the material database and manually set a mesh order. The mesh order is used by the simulation engine to select which material to use when two materials overlap. See the mesh order (optical) or mesh order (electrical) section for more details.

- MESH ORDER: Set the mesh order in this field if the OVERRIDE MESH ORDER FROM MATERIAL DATABASE option is selected. If the option is not selected, the field displays the material's default mesh order from the database. For example, a material of mesh order 1 will take precedence over a material of mesh order 2.

Note:Mesh order between 2D and 3D objects

- 2d objects always take priority over 3d objects. For example, a 3d cylinder overlapping a 2d rectangle will not create a hole in the 2d rectangle, regardless of their mesh order.

- 2d objects respect mesh order among themselves. For example, a 2d rectangle with RLC overlapping a 2d polygon with PEC. The material of the overlap is determined according to mesh orders.

- Please refer to the Understanding mesh order for overlapping objects for further information.

INDEX: The refractive index of the structure, when the material type is <Object defined dielectric>. The index must be greater than one.If <Object defined dielectric> is selected, then the INDEX property must be set.

-

-

- Anisotropic index: To specify the anisotropy, use the "Surface normal" option in the geometry tab.

- Spatially varying index: This is not supported in this 2D rectangle object.

-

- INDEX UNITS: Only relevant when specifying a spatially varying equation in the INDEX properly described above. Specify the units (nm, um, m) of the x,y,z position variables.

- GRID ATTRIBUTE NAME: Enter the name of the grid attribute that applies to this object, see the grid attribute section

Rotations tab

Rotate objects by setting the following variables:

- FIRST, SECOND, THIRD AXES: Select rotation axis. Up to three different rotations can be applied.

- ROTATION 1,2,3: The rotation of the object in a clockwise direction about each axis, measured in degrees.

| Note: Axis rotation This object does not support arbitrary angle of rotation on the non-normal axis. For example, with z axis being the normal, rotation of 30 degrees along z is allowed. However, rotation of 30 degrees along x or y axis is not allowed. Also note, the "Surface normal" option in the "Geometry tab" also rotates the object accordingly. |

Graphical Rendering tab

The graphical rendering tab is used to change how objects are drawn in the layout editor. The options are:

- RENDER TYPE: The options for drawing the objects are detailed or wireframe. Detailed objects are shaded and their transparency can be set using OVERRIDE COLOR OPACITY FROM MATERIAL DATABASE.

- DETAIL: This is a slider which takes values between 0 and 1. By default it is set to 0.5. Higher detail shows more detail, but increases the time required to draw objects. This setting has no effect on the simulation.

- OVERRIDE COLOR OPACITY FROM MATERIAL DATABASE: When unselected the opacity is determined from the material database. When selected, you can specify a value for ALPHA between 0 (transparent) and 1 (opaque) for the object, depending on how transparent you want the object to be.

2D Polygon - Simulation Object

FDTD MODE DGTD CHARGE HEAT FEEM

The object is defined in 2d surface and does not have thickness in the surface-normal direction. It can be used with 2D materials such as graphene, PEC and sampled 2d data.

Note: 2d objects always take priority over 3d objects when it comes to mesh orders. Please refer to the Understanding mesh order for overlapping objects for further information.

Here are some of the example structures that can be created using a 2D polygon object. To create any one of these structures, open the 2d_poly_examples.lsf and run the corresponding part of the script.

Geometry tab

- X, Y, Z: The center position of the object

Setting the vertices of the polygon object

The vertices of the polygon object can be edited by

- moving them with the mouse,

- manually editing the x,y location of each vertex in the polygon property editor,

- script command

For complex shapes, scripting in the structure group is usually best. Once the script has calculated the x,y vertex positions, they can be loaded into the polygon object with a single set("vertices",V); command. For example, use the following code to create an octagon shaped object.

# octagon properties

n_sides=8;

r=1e-6;

# x,y position of each corner

theta=linspace(0,360,n_sides+1);

theta=theta(1:n_sides);

x=r*cos(theta*pi/180);

y=r*sin(theta*pi/180);

# combine x,y into one vertices matrix

V=matrix(n_sides,2);

V(1:n_sides,1)=x(1:n_sides);

V(1:n_sides,2)=y(1:n_sides);

# add polygon object and set the vertices

addpoly;

set("vertices",V);

Getting and modifying polygon vertices

To get the polygon vertices, use the following command. The vertices will be returned in an Nx2 matrix. The columns of this matrix correspond to the X, Y positions of each vertex.

V=get("vertices");

?size(V);

To modify a polygon vertex, you must get the vertices matrix, modify the vertex matrix as desired, then re-apply it to the polygon object:

V=get("vertices");

V(1,1)=V(1,1)+1e-6; # change the x position of the first vertex by 1um.

set("vertices",V);

Material tab

The material options are as follows:

- MATERIAL: The material assigned to a 2D polygon is filtered. It can only accept graphene, PEC(perfect electric conductor), sampled 2d data material types.

- OVERRIDE MESH ORDER FROM MATERIAL DATABASE: Select to override the mesh order from the material database and manually set a mesh order. The mesh order is used by the simulation engine to select which material to use when two materials overlap. See the mesh order (optical) or mesh order (electrical) section for more details.

- MESH ORDER: Set the mesh order in this field if the OVERRIDE MESH ORDER FROM MATERIAL DATABASE option is selected. If the option is not selected, the field displays the material's default mesh order from the database. For example, a material of mesh order 1 will take precedence over a material of mesh order 2.

Note:Mesh order between 2D and 3D objects

- 2d objects always take priority over 3d objects. For example, a 3d cylinder overlapping a 2d rectangle will not create a hole in the 2d rectangle, regardless of their mesh order.

- 2d objects respect mesh order among themselves. For example, a 2d rectangle with RLC overlapping a 2d polygon with PEC. The material of the overlap is determined according to mesh orders.

- Please refer to the Understanding mesh order for overlapping objects for further information.

Rotations tab

Rotate objects by setting the following variables:

- FIRST, SECOND, THIRD AXES: Select rotation axis. Up to three different rotations can be applied.

- ROTATION 1,2,3: The rotation of the object in a clockwise direction about each axis, measured in degrees.

| Note: Axis rotation This object does not support an arbitrary angle of rotation on the non-normal axis. For example, with z axis being the normal, rotation of 30 degrees along z is allowed. However, rotation of 30 degrees along x or y axis is not allowed. Also note, the "Surface normal" option in the "Geometry tab" also rotates the object accordingly. |

Graphical Rendering tab

The graphical rendering tab is used to change how objects are drawn in the layout editor. The options are:

- RENDER TYPE: The options for drawing the objects are detailed or wireframe. Detailed objects are shaded and their transparency can be set using OVERRIDE COLOR OPACITY FROM MATERIAL DATABASE.

- DETAIL: This is a slider which takes values between 0 and 1. By default it is set to 0.5. Higher detail shows more detail, but increases the time required to draw objects. This setting has no effect on the simulation.

- OVERRIDE COLOR OPACITY FROM MATERIAL DATABASE: When unselected the opacity is determined from the material database. When selected, you can specify a value for ALPHA between 0 (transparent) and 1 (opaque) for the object, depending on how transparent you want the object to be.

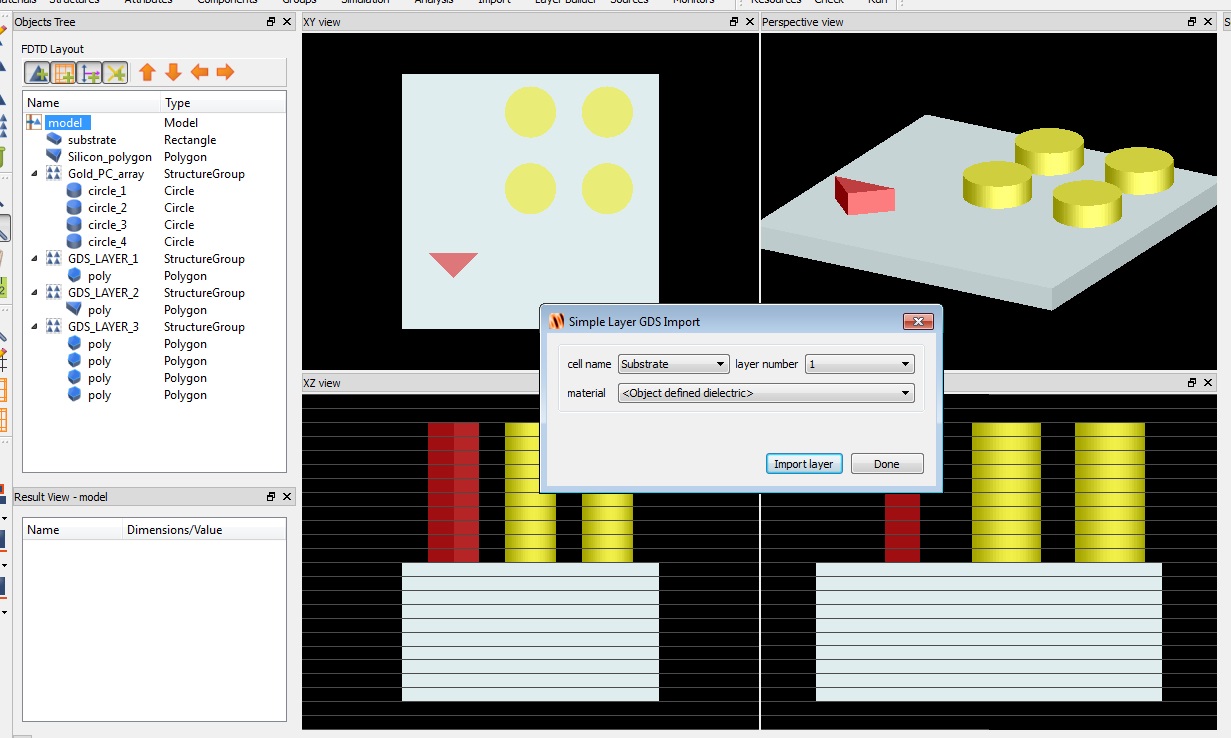

Complex structures:

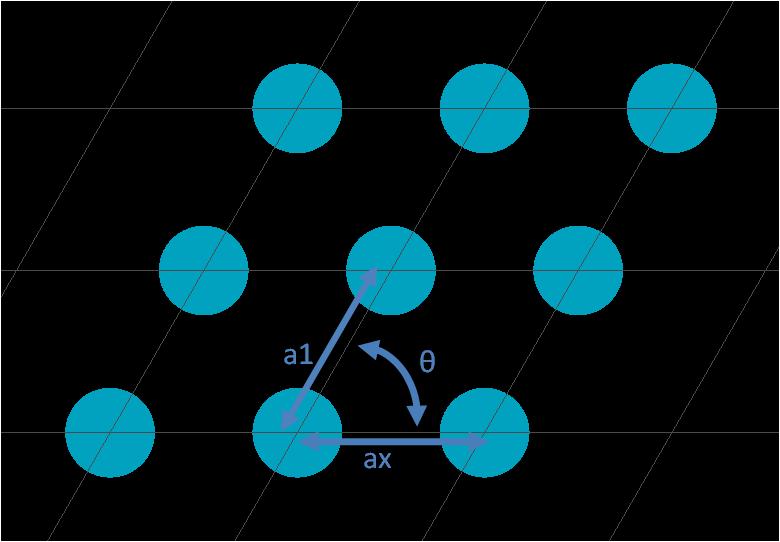

Structure group to create arrays of objects

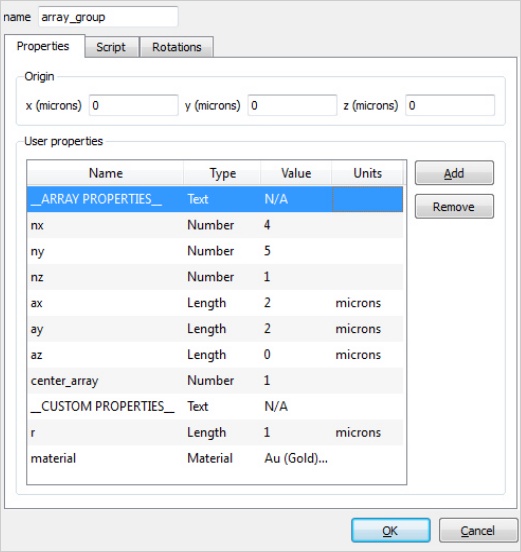

This page provides a structure group that can be used to create arrays of other objects. The simulation file usr_array_structure_group.fsp contains a structure group that will create an array of objects that are placed within the group.

For example, suppose we want to create an array of hemispheres.

| Step 1 Create the structure that you want to array. In this case, we have created a hemisphere using the surface object. If your structure is composed of more than one primitive, remember to group the primitives together. |

| ||||||

| Step 2 Change the name of your structure to 'object'. Move your structure named 'object' into the array_group. This is most easily accomplished with the reposition arrows (circled in the screenshot to the right). |

| ||||||

| Step 3 Setup the array structure group as required.

It's possible to add custom properties to this object to modify each instance of the original object. In this example, we have radius and material properties to adjust the hemisphere. |

| ||||||

| Step 4 The array structure group will automatically create an array of the objects. |

|

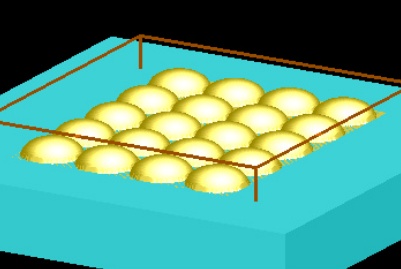

For another example of a structure group that can be used to create arrays, see the Structure groups page. This page provides a detailed description of how to create your the 2D array object shown below.

Tips for creating structures with rounded corners

This section describes how to create objects with rounded corners. The example file here was created in FDTD, but these structures can be found in the component libraries of other products as well.

Creating objects with rounded corners

Method 1:

Objects with rounded corners can be created with the polygon object. The simulation file usr_round_corners.fsp contains an n-sided equilateral shape with rounded corners created using the polygon primitive and then extruding. This object can also be accessed via the object library. By default, one corner of the object always points in the +X direction. The rotation tab of the structure group can be used to rotate the object.

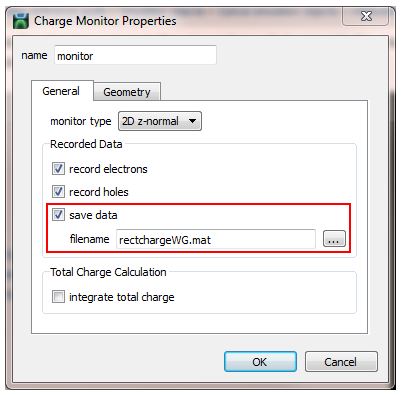

Method 2: